Scattering device used for powder treatment and powder scattering machine

A technology of dispersing machine and powder, which is applied in the direction of grain processing, etc., can solve the problems of difficult to handle and cannot be used normally, and achieve the effects of convenient operation, efficient dispersing and efficient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

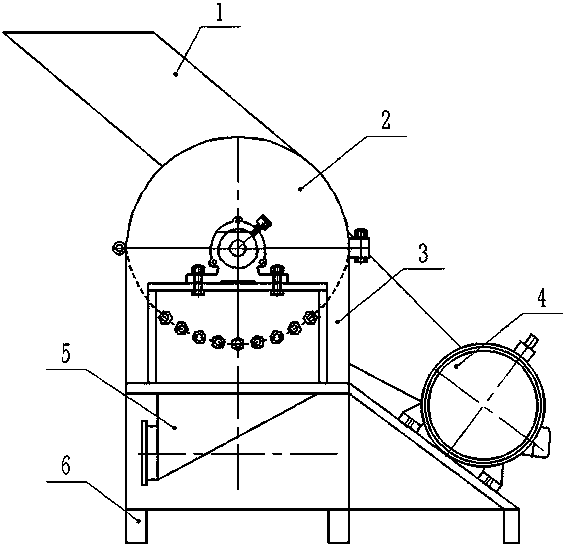

[0025] refer to figure 1 The powder dispersing machine includes a frame 6 , a dispersing device for powder processing, an input hopper 1 and an output hopper 5 .

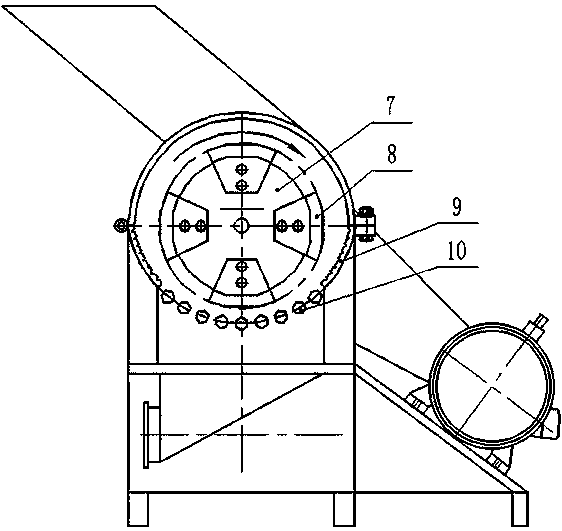

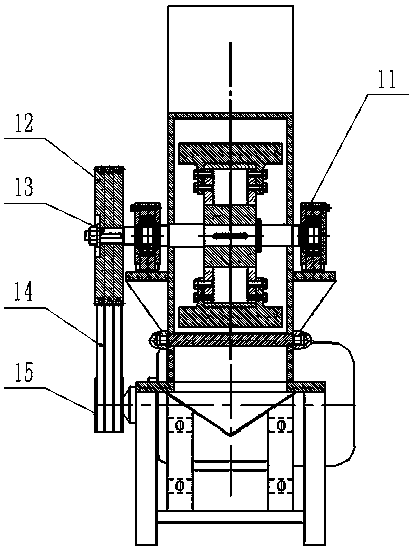

[0026] refer to figure 2 , the dispersing device used for powder processing includes a housing, a dispersing motor 4, a rotor disk 7 and

[0027] The stator part; wherein the shell is arranged on the frame 6, and the upper cavity 2 and the lower cavity 3 are installed inside the shell. One end of the upper cavity 2 and the lower cavity 3 is connected by a hinge structure, and the other end is connected by a bolt and nut assembly The detachable connection is integrated; the dispersing motor 4 is located at the side of the frame 6, and the output end of the dispersing motor 4 is connected to a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap