Direct-blowing type drying cylinder cover welded assembly

A dryer hood, direct-blowing technology, applied in textiles and papermaking, papermaking machines, dryers, etc., can solve the problems of large steam consumption, increase production costs, reduce production efficiency, etc., to improve production efficiency, The effect of reducing production costs and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

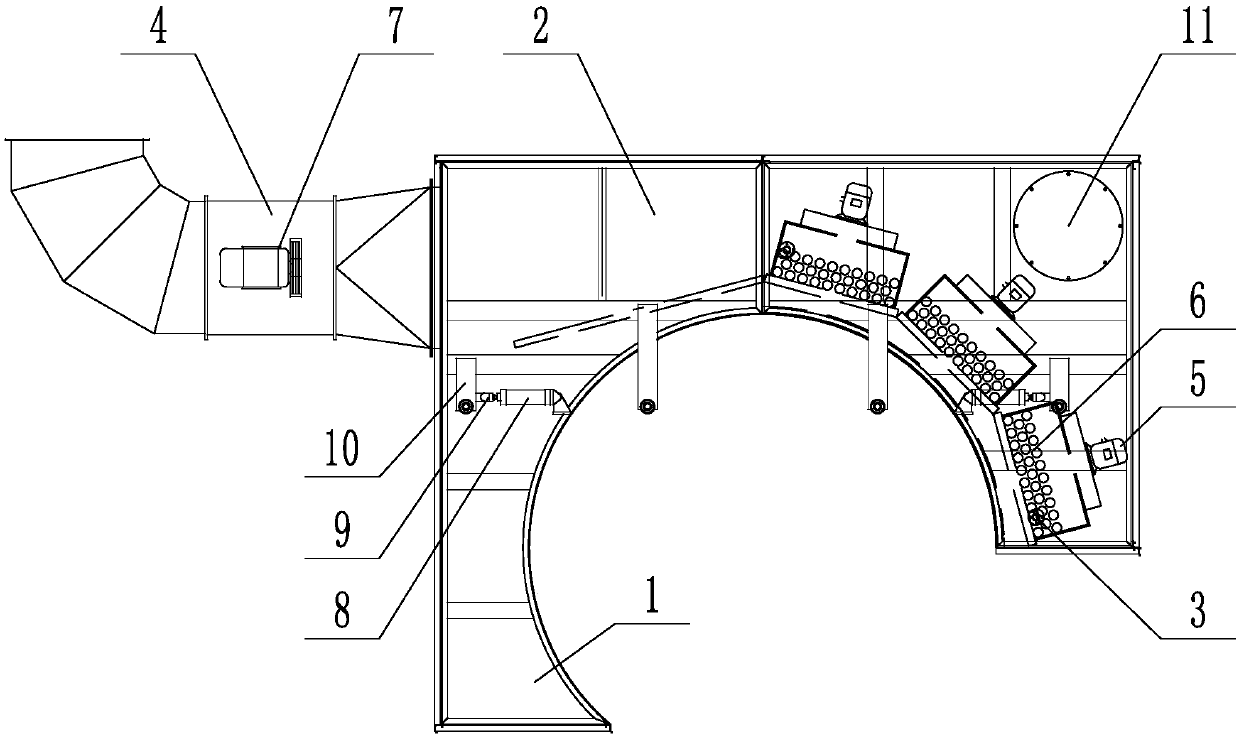

[0007] Such as figure 1 As shown, the present invention includes a main body 1, a drying cover 2, a steam inlet pipe 3, an air outlet pipe 4, a blower 5, a cooling fin 6 and an exhaust fan 7. A group of cylinders 8 are respectively installed at the left and right ends of the inner side of the top, and a group of support plates 10 are installed on the front ends of each group of cylinders 8 through the cylinder shaft 9, and the two groups of support plates 10 are welded to the drying cover 2 at the top of the main body 1 Above, the inside of the upper right end of the drying cover 2 is provided with a wet paper inlet 11, and the lower right corner of the main body 1 is provided with a steam inlet pipe 3, and the end of the steam inlet pipe 3 is connected with three sets of cooling fins along the bottom of the arc-shaped main body 1. 6. A set of blowers 5 is installed above each set of cooling fins 6 , an air outlet pipe 4 is installed outside the upper left corner of the drying co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap