On-line separation device for enzymatic hydrolysate

A technology of separation device and enzymatic solution, applied in the direction of liquid separation, immiscible liquid separation, liquid separation auxiliary equipment, etc., can solve the problems of high labor intensity, unstable separation effect, time-consuming and labor-intensive, etc., and achieve the degree of automation And the effect of high accuracy, reducing static layering process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the examples, which are only used to illustrate the present invention and not limit the scope of the present invention.

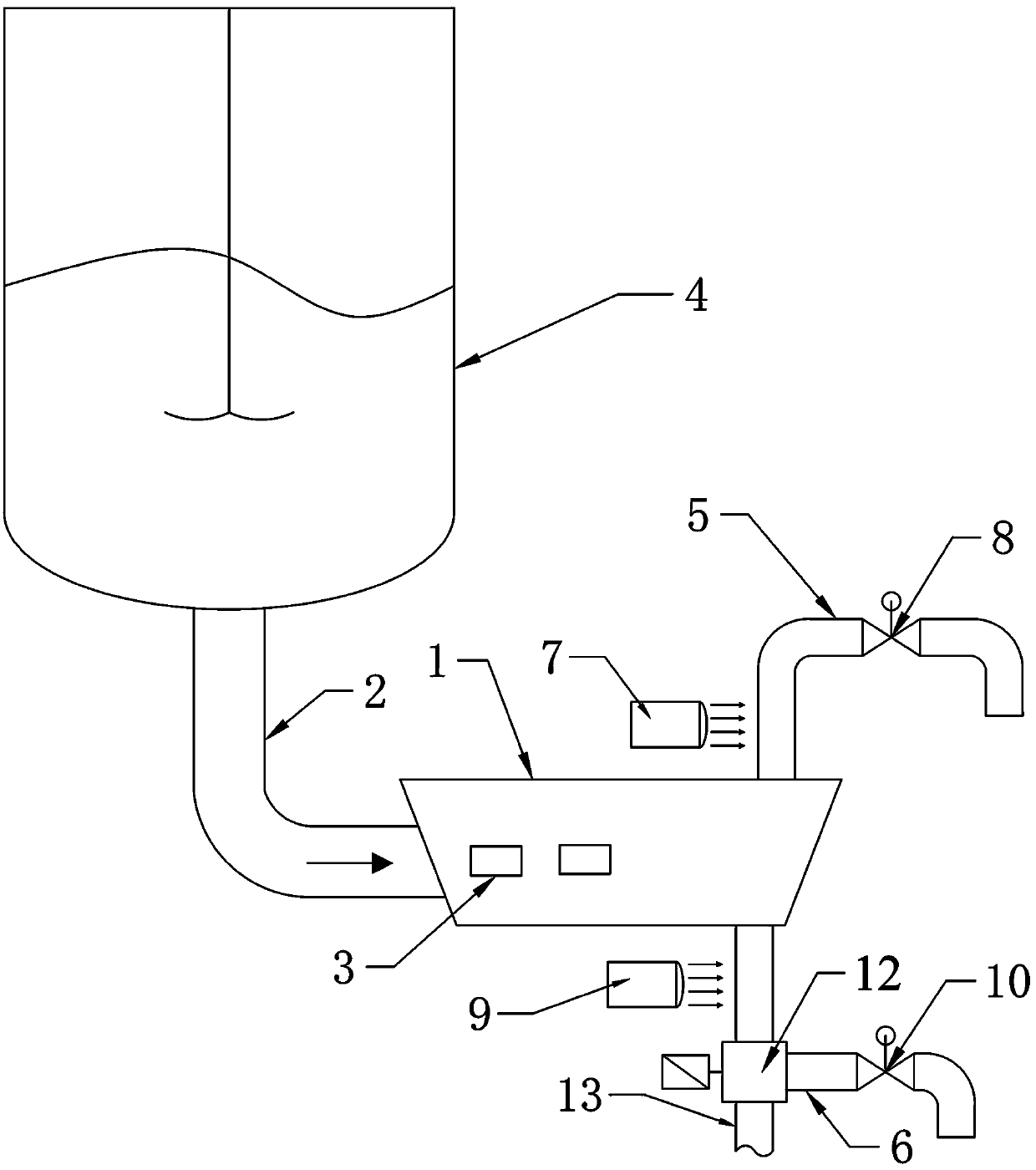

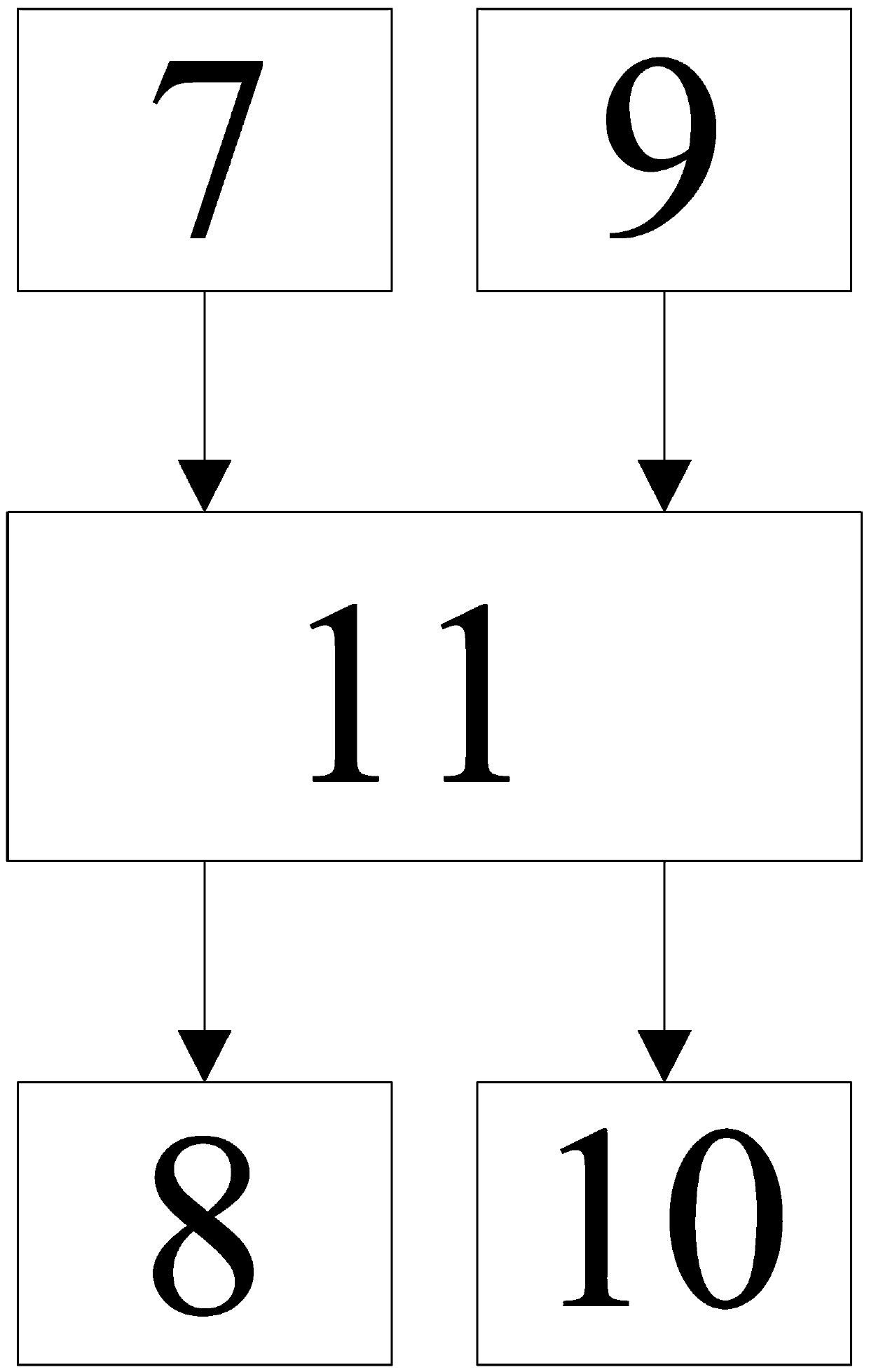

[0020] Such as Figure 1-2 Among them, an on-line separation device for enzymolysis liquid, including a separation container 1, an inlet pipe 2 and a vibrator 3, the two ends of the inlet pipe 2 are respectively connected to the separation container 1 and the enzymolysis tank 4, and the vibrator 3 is built in The side of the separation container 1 close to the entrance, the height of the separation container 1 is one-fifth of the width to form a shallow separation pool, the direction in which the mixed liquid flows in and the direction of separation are perpendicular to each other, so that the separation effect of the oil and the enzymolysis liquid More prefe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap