Soil remediation agent used for heavy metal pollution and preparation method thereof

A soil remediation agent and a technology of heavy metals, applied in the field of soil remediation, can solve the problems of limited use of soil and the disappearance of soil value, etc., and achieve the effect of good removal effect, wide sources and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

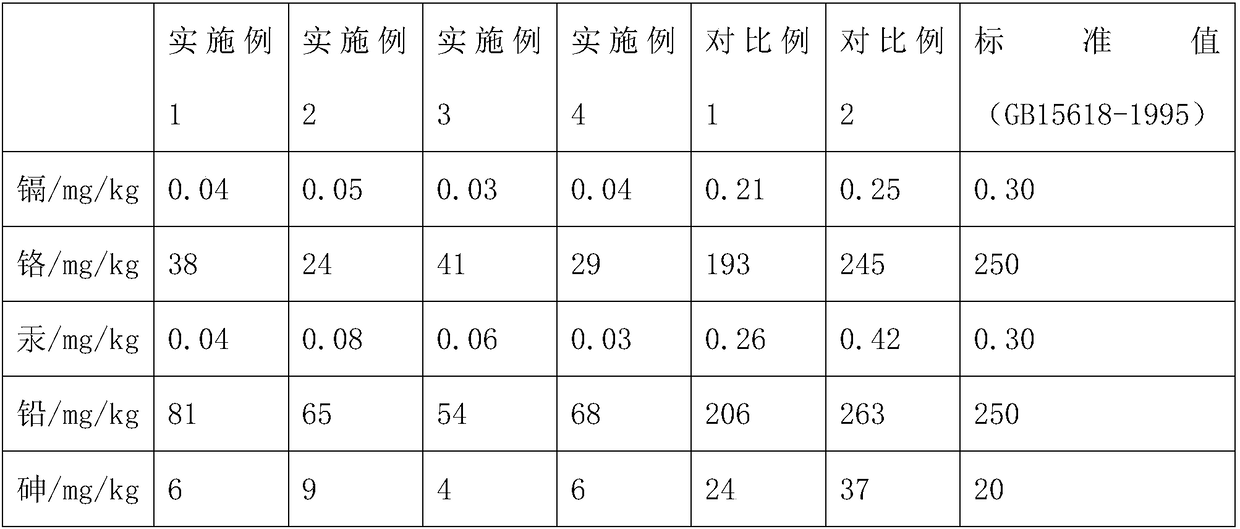

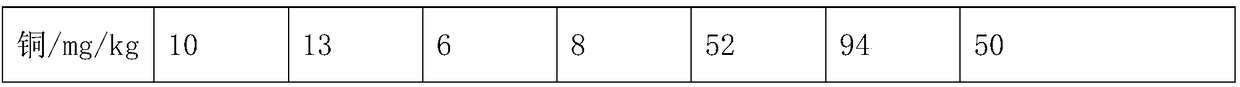

Examples

Embodiment 1

[0019] A soil remediation agent for heavy metal pollution, comprising the following raw materials in parts by weight: 45 parts of clay minerals, 24 parts of straw, 10 parts of chitosan, 5 parts of alfalfa, 6 parts of polydimethyldiallylammonium chloride , 8 parts of water-soluble polyvinyl alcohol, 1.5 parts of guar gum, 4 parts of sodium carbonate, 5 parts of metal oxide and 2 parts of sodium humate, clay minerals include attapulgite and a mixture of montmorillonite and kaolin. The metal oxide includes a mixture of magnesium oxide, sodium oxide and potassium oxide, and the straw is sugarcane straw.

[0020] The preparation method of the soil remediation agent for heavy metal pollution, the specific steps are as follows:

[0021] Step 1, mixing sodium carbonate with straw and heating at 480 degrees Celsius in isolation from the air, naturally cooling to normal temperature and crushing to 160 mesh to obtain the first mixture;

[0022] Step 2, the alfalfa is crushed, then extracte

Embodiment 2

[0027] A soil remediation agent for heavy metal pollution, comprising the following raw materials in parts by weight: 52 parts of clay minerals, 28 parts of straw, 11.5 parts of chitosan, 6 parts of alfalfa, 7.5 parts of polydimethyldiallylammonium chloride , 11 parts of water-soluble polyvinyl alcohol, 2 parts of guar gum, 4.8 parts of sodium carbonate, 7.5 parts of metal oxides and 3 parts of sodium humate, clay minerals include a mixture of sepiolite, palygorskite and illite. The particle diameter of the clay mineral is 0.12mm.

[0028] The preparation method of the soil remediation agent for heavy metal pollution, the specific steps are as follows:

[0029] Step 1, mixing sodium carbonate with straw and heating at 450 degrees Celsius in isolation from the air, naturally cooling to normal temperature and crushing to 180 mesh to obtain the first mixture;

[0030] Step 2, crush the alfalfa, then extract it with 0.75mol / L hydrochloric acid solution for 88 minutes, the mass rat

Embodiment 3

[0035] A soil remediation agent for heavy metal pollution, comprising the following raw materials in parts by weight: 61 parts of clay minerals, 30 parts of straw, 13 parts of chitosan, 7.5 parts of alfalfa, and 8 parts of polydimethyldiallylammonium chloride , 14 parts of water-soluble polyvinyl alcohol, 2.5 parts of guar gum, 5.5 parts of sodium carbonate, 9 parts of metal oxides and 4.2 parts of sodium humate, clay minerals include palygorskite, illite, montmorillonite and kaolin mixture. The particle diameter of the clay mineral is 0.08mm.

[0036] The preparation method of the soil remediation agent for heavy metal pollution, the specific steps are as follows:

[0037] Step 1, mixing sodium carbonate with straw and heating at 485 degrees Celsius in isolation from air, naturally cooling to normal temperature and crushing to 200 mesh to obtain the first mixture;

[0038] Step 2, the alfalfa is crushed, then extracted with 0.75mol / L hydrochloric acid solution for 88 minutes,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap