Seed film tape maker

A seed film and film tape technology, which is applied in the field of agricultural production, can solve the problems of low manual operation efficiency, large workload, and is not suitable for large-scale promotion, and achieves the effects of high production efficiency, reasonable structure and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

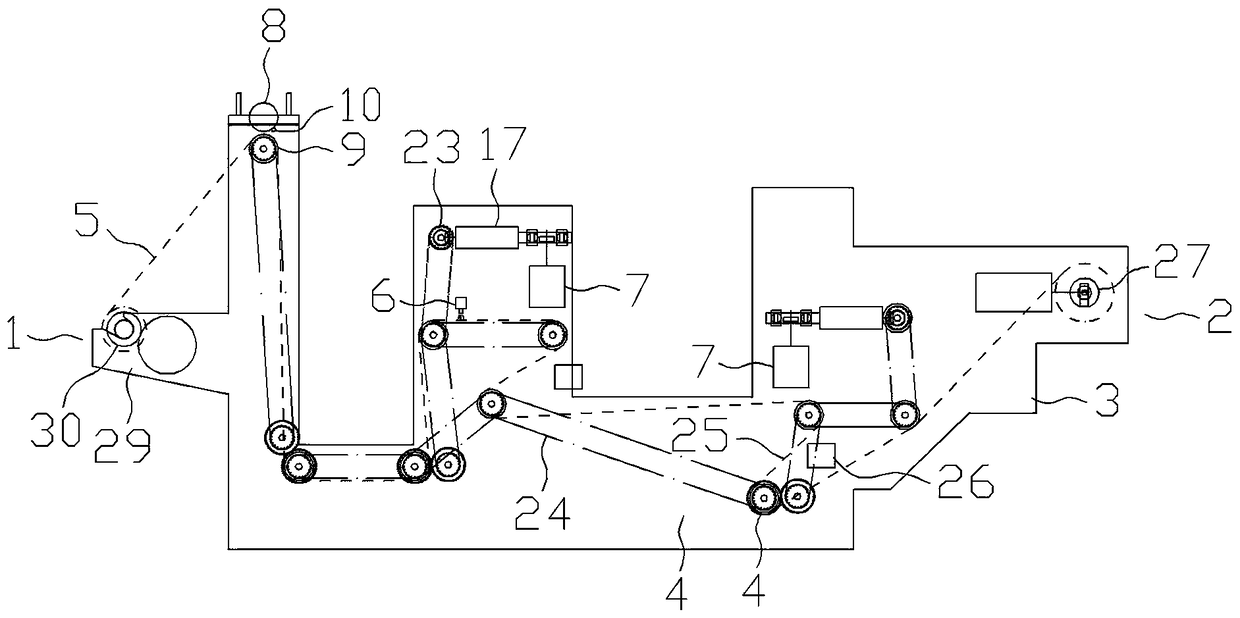

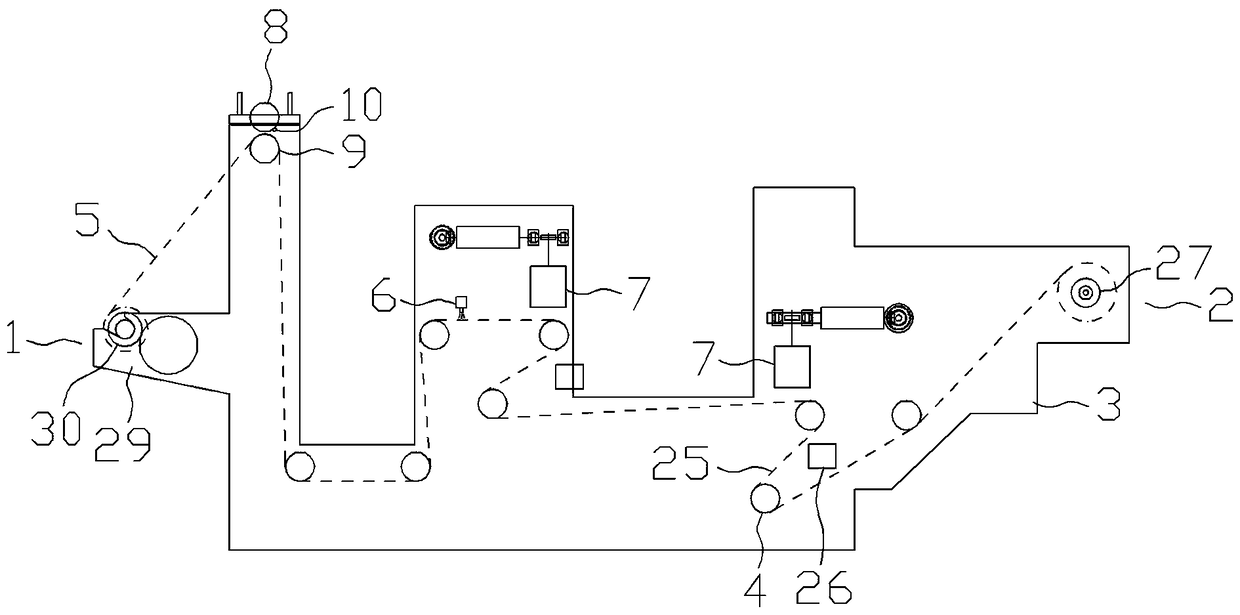

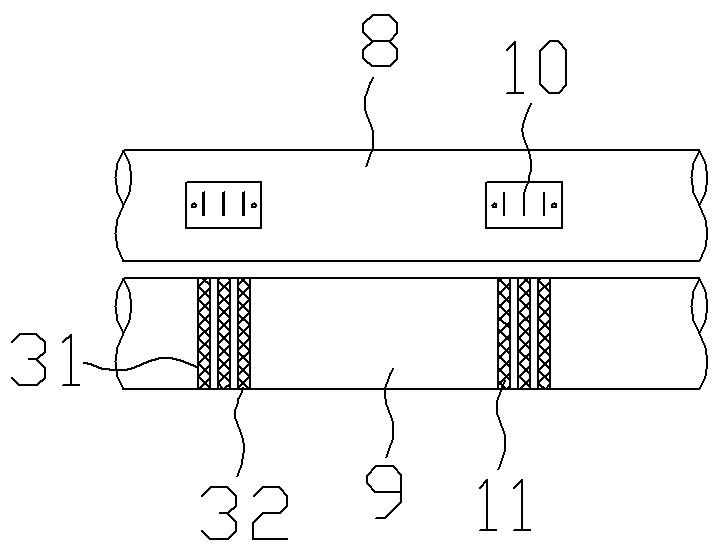

[0012] Such as Figure 1-6 As shown, the seed film belt machine includes a film belt machine body 3 provided with an input end 1, an output end 2 and a control device. The film belt machine body 3 is provided with several roller shafts 4 driven by a driving device, which can make the film belt 5 is conveyed from the input end 1 to the output end 2 under the path arranged by the roller shaft 4, and the film belt machine body 3 is provided with a pair of cutting knives sequentially from the input end 1 to the output end 2 above the route that the film belt 5 passes through. Roller, viscose nozzle 6, spreading device 7 for spreading seeds and spreading device 7 for spreading fertilizer, the cutter pair of rollers includes adjacently arranged knife roller 8 and bearing knife roller 9, and the peripheral surface of knife roller 8 is distributed with cuts Knife 10, the knife bearing roller 9 is provided with the knife bearing portion 11 that cooperates with the cutting knife 10, and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap