Spraying method for electric arc spraying coating of well drilling water string and hole sealing coating thereof

An arc spraying and water riser technology, which is applied in the coating, the device for coating liquid on the surface, the spraying device, etc., can solve the problems of complicated spraying of sealing agent, unsatisfactory coating quality and complicated processing technology, etc. To achieve the effect of simple and reliable spraying process, saving spraying operation time and spraying site, and simple device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

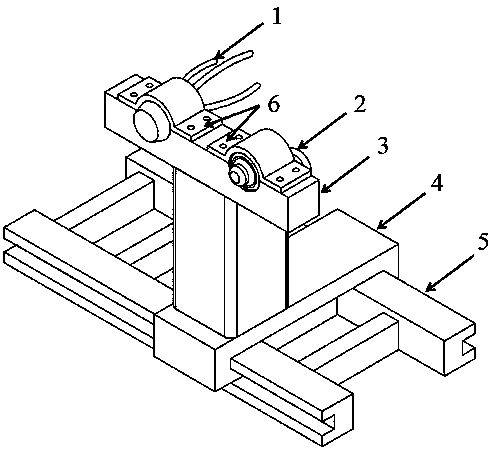

[0043] 1. The arc spray gun and the sealing spray gun are installed at an interval of 1 m.

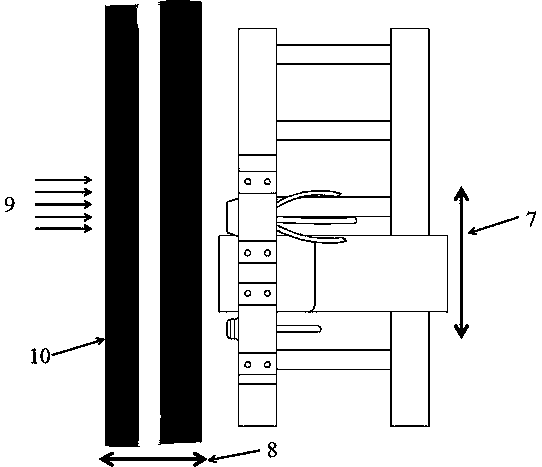

[0044] 2. Spray Al with a diameter of 3.0 mm on the pretreated waterproof casing by arc spraying technology 2 o 3 / Al-Zn powder core wire.

[0045] 3. When spraying the metal coating for the last time, open the sealing spray gun and apply a sealant at the same time. The dry film thickness of the sealing coating is 30-80 microns.

[0046] The test piece was subjected to a corrosion test in 3.5% NaCl solution, and the test piece was taken out, and it was found that the surface morphology of the composite coating of the test piece did not change, and all coating surfaces did not appear blistering, rusting, peeling, etc.

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is: in step 1, adjust the distance between the spray guns according to the sealing agent; in step 2, select the Al-Mg-Ti-RE powder core wire material with a diameter of 3.0 mm; in step 3, seal the hole The agent is sprayed twice, and the dry film thickness of the seal coat is 50-100 microns.

[0049] The test piece was subjected to a corrosion test in 3.5% NaCl solution, and the test piece was taken out, and it was found that the surface morphology of the composite coating of the test piece did not change, and all coating surfaces did not appear blistering, rusting, peeling, etc.

Embodiment 3

[0051] The difference between this embodiment and Example 1 is: in step 1, the spray gun spacing is adjusted according to the sealing agent; in step 2, the Fe-Cr-Ni powder core wire material with a diameter of 3.0 mm is selected; The dry film thickness of the seal coat is 50-100 microns.

[0052] The test piece was subjected to a corrosion test in 3.5% NaCl solution, and the test piece was taken out. It was found that the surface morphology of the composite coating of the test piece did not change, and all the coating surfaces did not appear blistering, rusting, peeling, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap