Colored Photosensitive Resin Composition, Color Filter and Image Display Device

A technology of photosensitive resin and composition, applied in the directions of instruments, optics, filters, etc., can solve the problems of easy generation of water streaks, lamination residues, etc., and achieve the effects of no water streaks and lamination residues, and excellent solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0208] Synthesis Example 1: Triazine Compound

[0209] As a triazine derivative, a compound of the following Chemical Formula 13 was produced as follows.

[0210] Add 18.4 parts by weight of 2-chloro-4,6-diamino-1,3,5-triazine and 21 parts by weight of 3-(2-ethylhexyloxy)propylamine to 100 parts by weight of water. React for 1 hour. The resulting reactant was reacted at 85°C for 5 hours. The residue obtained by leaching the obtained reactant was washed with water, and then left to stand overnight in a thermostat at 100° C. for drying to obtain a compound of the following chemical formula 13.

[0211] [chemical formula 13]

[0212]

Synthetic example 2

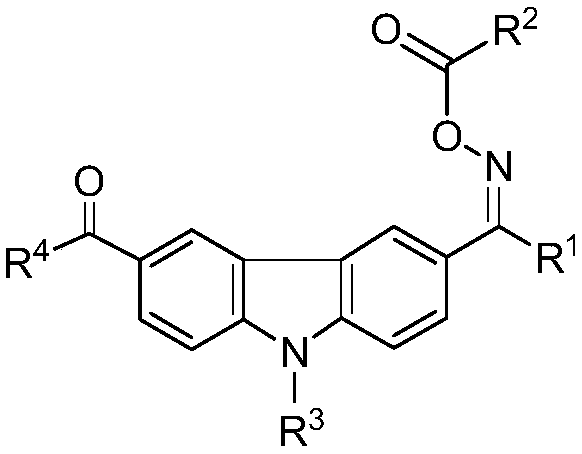

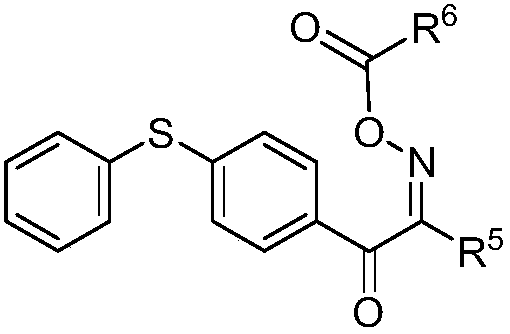

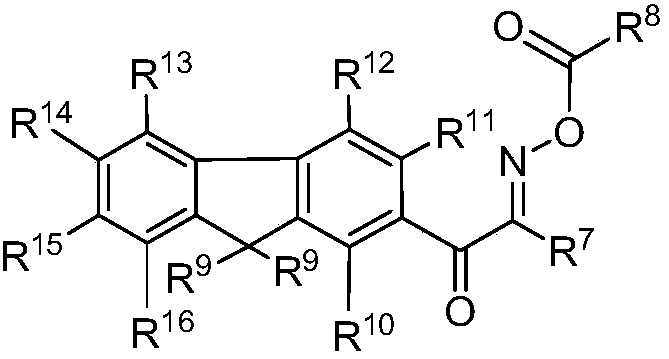

[0213] Synthesis example 2: the compound of chemical formula 3

[0214] As the oxime compound, the compound of Chemical Formula 3 was produced as follows.

[0215] Reactant 1

[0216] Under a nitrogen atmosphere, 200.0 g of fluorene, 268.8 g of potassium hydroxide, and 19.9 g of potassium iodide were dissolved in 1 L of anhydrous dimethyl sulfoxide, and the reactant was maintained at 15° C., and then bromoethane 283.3 g was slowly added over 2 hours. g. The reaction was stirred at 15°C for 1 hour. Then, after adding 2 L of distilled water to the reactant and stirring for 30 minutes, the product was extracted with 2 L of dichloromethane, and after the extracted organic layer was washed twice with 2 L of distilled water, the recovered organic layer was dried with anhydrous magnesium sulfate. Then, the solvent was distilled off under reduced pressure, and the resulting product was fractionally distilled under reduced pressure to obtain 248.6 g of a pale yellow reactant 1 (9,9-die

Synthetic example 3

[0223] Synthesis Example 3: Resin B-1

[0224] Prepare a flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube. On the other hand, as a monomer dropping funnel, prepare 74.8 g (0.20 mol) of benzylmaleimide and 43.2 g of acrylic acid. (0.30 mol), 118.0 g (0.50 mol) of vinyltoluene, 4 g of tert-butyl peroxy-2-ethylhexanoate, and 40 g of propylene glycol monomethyl ether acetate (PGMEA) were charged and mixed with stirring, As a chain transfer agent dropping tank, what was prepared by adding 6 g of n-dodecane mercaptan and 24 g of PGMEA and stirring and mixing them was prepared. Thereafter, 395 g of PGMEA was introduced into the flask, and the atmosphere in the flask was replaced with nitrogen from air, and then the temperature of the flask was raised to 90° C. while stirring. Next, the monomer and the chain transfer agent were added dropwise from the dropping funnel. During the dropwise addition, each was carried out

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap