Glucose composition, microbial fermentation raw material, and method for producing chemical product

A technology of microbial fermentation and composition, applied in the directions of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of low fermentation yield and difficult fermentation, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

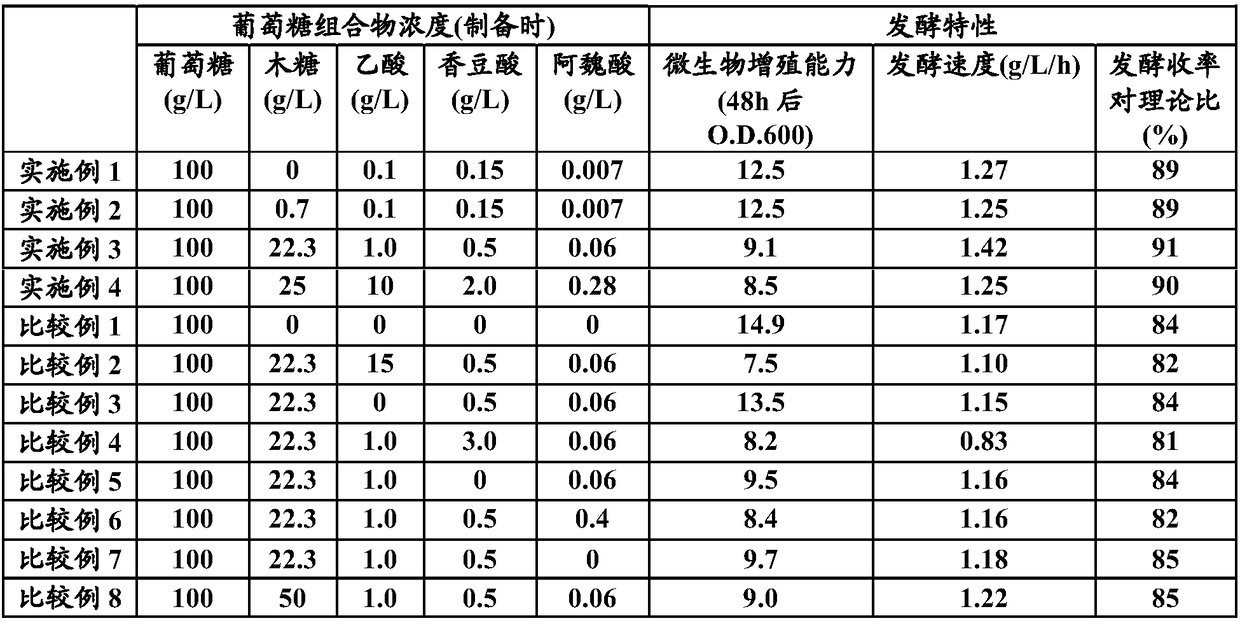

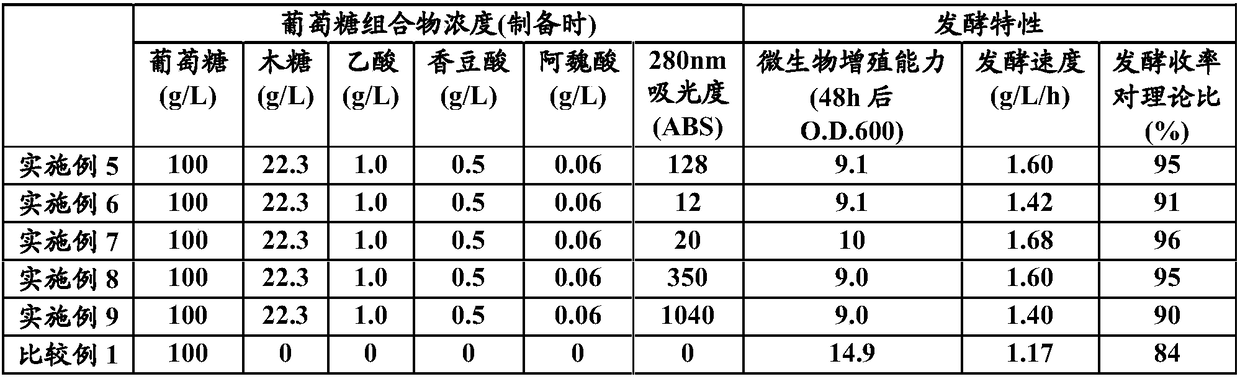

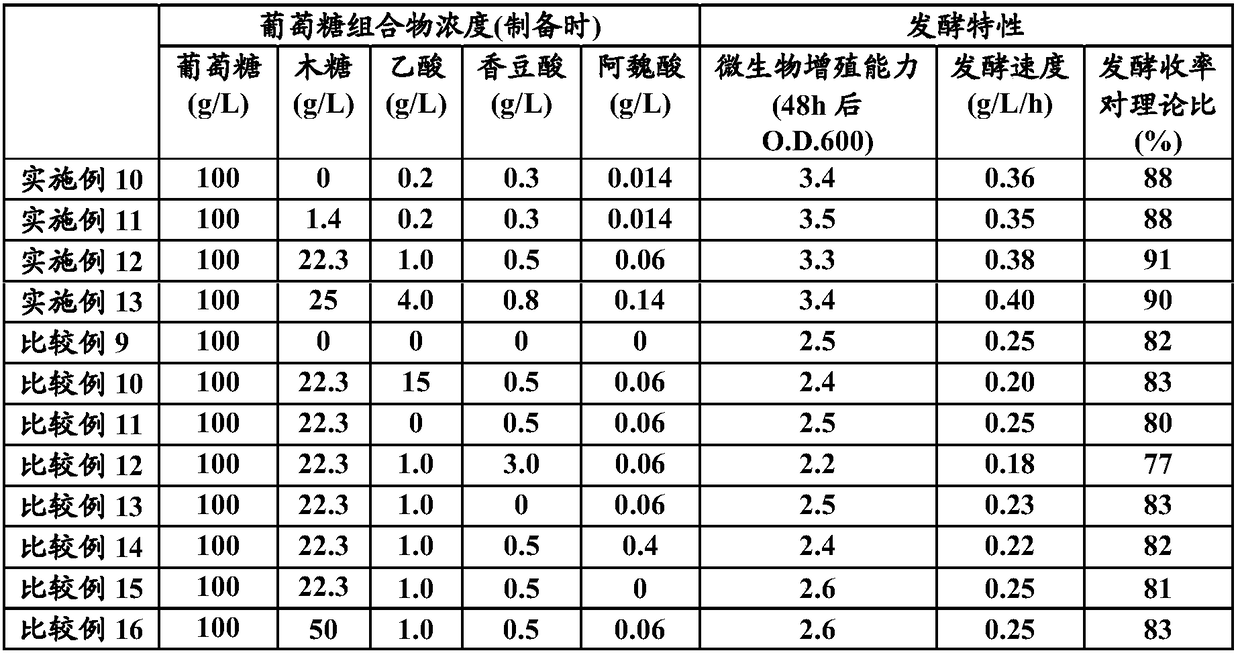

Examples

Embodiment

[0060] Examples are given below to describe the present invention in detail. However, the present invention is not limited by these Examples.

reference example 1

[0061] (Reference Example 1) Preparation of Yeast (Saccaromyces cereveciae) for Ethanol Fermentation Evaluation Test

[0062] As the ethanol-fermenting microorganism, Saccharomyces cereveciae (strain of red wine yeast OC2, NBRC2260) was used. YPD medium (the peptone, yeast extract concentrate, and glucose concentrate were sterilized in an autoclave at 121°C for 20 minutes, and prepared into 20 g / L peptone, 10 g / L yeast extract, and 10 g / L glucose. Culture medium) 2 mL was added to a test tube, and a platinum loop was used to inoculate yeast colonies formed on YPD agar medium plate culture (30° C., 1 to 2 days) in a clean bench. This was cultured with reciprocating shaking at 50°, 30° C., and 120 rpm using a shaker (TAITEC Co., Ltd., BIO-SHAKER BR-40LF) for 24 hours to obtain a preculture solution. The preculture solution was centrifuged at 15,000×g for 5 minutes at 4° C., the supernatant was removed, and suspended in 2 mL of physiological saline to obtain a preculture cell

reference example 2

[0063] (Reference example 2) Measurement of sugar and ethanol concentration

[0064] The concentrations of glucose and xylose contained in the sugar solution, and the concentration of ethanol produced by fermentation were quantified by comparison with standard samples under the HPLC conditions shown below.

[0065] Column: Shodex SH1011 (manufactured by Showa Denko Co., Ltd.)

[0066] Mobile phase: sulfuric acid 5mM (flow rate 0.6mL / min)

[0067] Reaction solution: no

[0068] Detection method: RI (differential refractive index)

[0069] Temperature: 65°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap