Fructus rosae laevigatae standard decoction lyophilized powder and production process thereof

A production process and freeze-dried powder technology, applied in the field of Jinyingzi standard decoction freeze-dried powder and its production technology, can solve the problems of collapse, high viscosity of freeze-dried powder, unable to achieve ideal freeze-drying effect, etc., and achieve smooth surface. , Low hygroscopicity, and the effect of improving freeze-drying rate and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

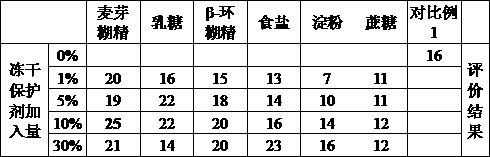

[0022] A standard decoction freeze-dried powder of Fructus Rosa Fructus, take 2 mL of standard decoction of Fructus Rosa Fructus, add 10% freeze-drying protective agent, freeze-dry to obtain freeze-dried powder. The lyoprotectant is maltodextrin. The density of described Fructus Rosa Rosa standard decoction is 1g / mL. The freezing temperature of the freeze-drying is -50°C, and the freezing time is not less than 3 hours; after the freezing is completed, the temperature is raised to -35°C within 8 minutes, and after being maintained for 20 hours, the temperature is raised to -30°C and maintained for 18 hours; Keep at -20°C for 10 hours, continue to raise the temperature to -10°C, and keep for 5 hours; raise the temperature to 30°C within 8 minutes for analysis and drying.

[0023] Adding a freeze-drying protective agent into a certain amount of standard decoction of Rosa chinensis can effectively prevent the freeze-dried product from excessive viscosity and serious collapse durin

Embodiment 2

[0026] The difference between Example 2 and Example 1 is that 2 mL of the standard decoction of Fructus Rosa Radix is taken, 1% of lyoprotectant is added, and the lyophilized powder can be obtained after lyophilization. The lyoprotectant is maltodextrin. The freezing temperature of the freeze-drying is -55°C, and the freezing time is not less than 2 hours; after the freezing is completed, the temperature is raised to -40°C within 5 minutes, and after being maintained for 15 hours, the temperature is raised to -33°C and maintained for 15 hours; Keep at -25°C for 5 hours, continue to raise the temperature to -15°C, and keep for 3 hours; within 5 minutes, raise the temperature to 20°C for analysis and drying.

[0027] The sublimation temperature is set to -40°C and -30°C, the production efficiency is high and the product quality is good. Catechin has various functions such as anti-tumor, anti-oxidation, anti-bacteria, and protection of heart and brain organs. The freeze-dried pro

Embodiment 3

[0029] The difference between Example 3 and Example 1 is that 2 mL of the standard decoction of Fructus Rosa Rosa Fructus is taken, 30% of lyoprotectant is added, and the lyophilized powder can be obtained after lyophilization. The lyoprotectant is maltodextrin. The freezing temperature of the freeze-drying is -45°C, and the freezing time is not less than 4 hours; after the freezing is completed, the temperature is raised to -32°C within 10 minutes, and after being maintained for 25 hours, the temperature is raised to -28°C and maintained for 20 hours; Keep at -15°C for 15 hours, continue to raise the temperature to -5°C, and keep for 10 hours; within 10 minutes, raise the temperature to 35°C for analysis and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap