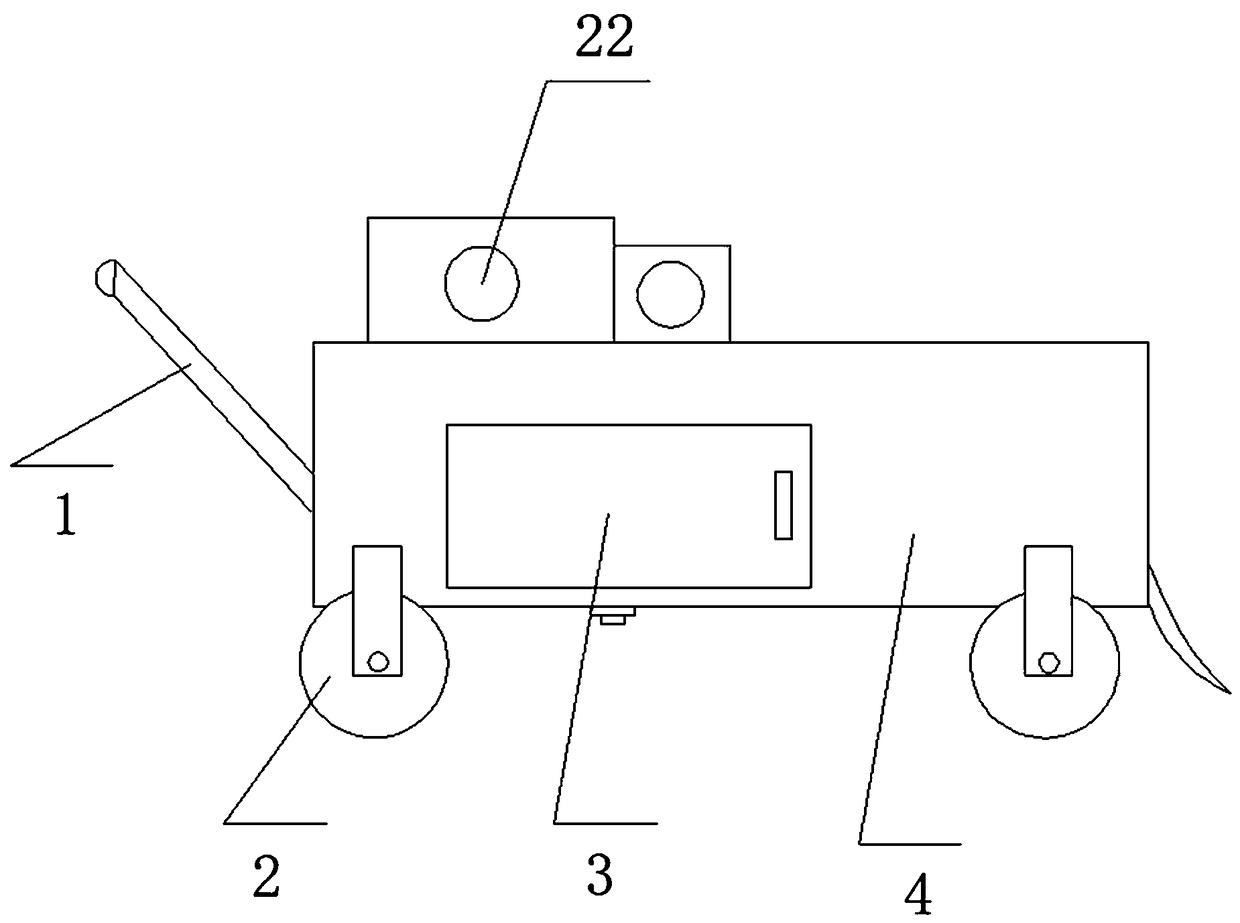

Sweet potato vine collection device for agricultural production

A collection device and technology of sweet potato seedlings are applied in the field of agricultural machinery to achieve the effects of reducing workload, wide application range and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

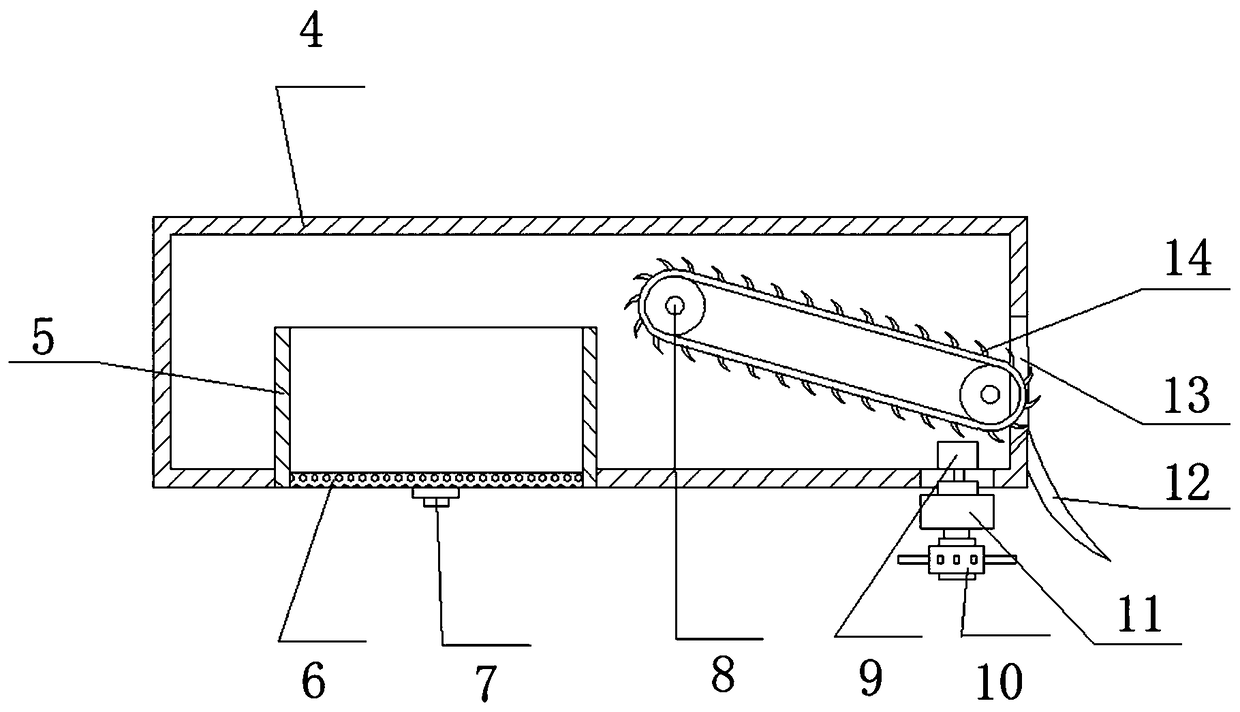

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

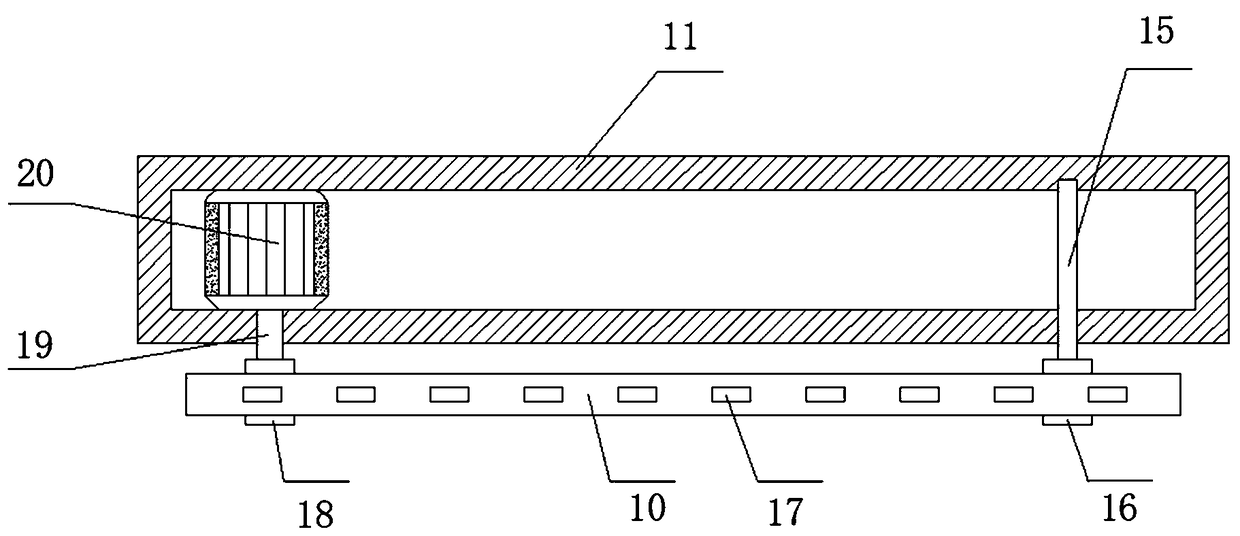

[0023] refer to Figure 1-4 , a sweet melon seedling collection device for agricultural production, comprising a car body 4, a rectangular groove is provided on one side of the bottom outer wall of the car body 4, and the inner walls of both sides of the rectangular groove are connected with the same storage case 5 by bolts, the storage case 5 The bottoms of the inner walls on both sides are connected with the same horizontally placed screen 6 through tension springs, and the bottom outer wall of the screen 6 is connected with a vibration motor 7 through bolts, and the inner walls at both ends of the car body 4 are connected with the same obliquely placed electric motor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap