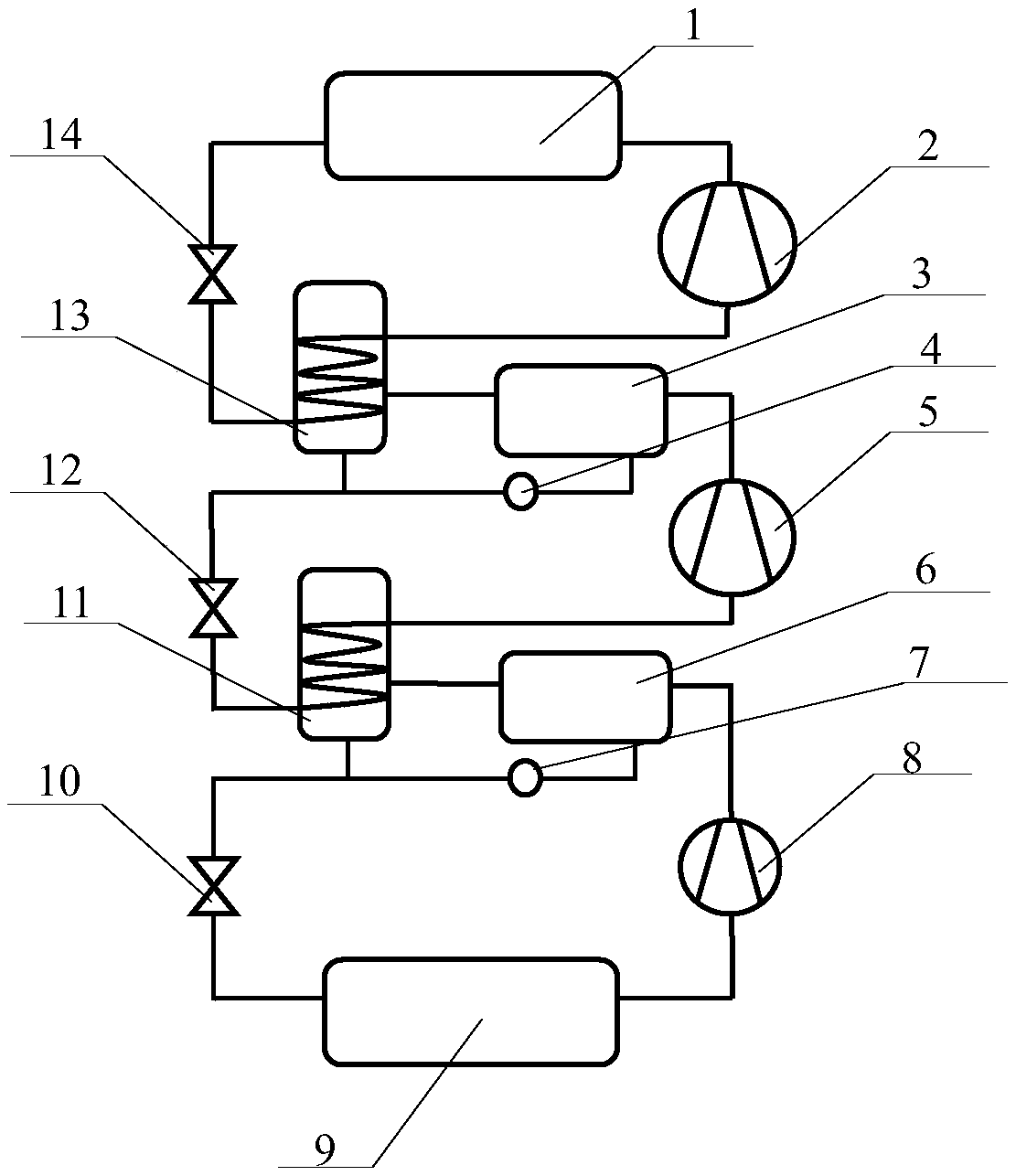

Three-stage cascade direct contact condensing and refrigerating circulating system

A circulation system and direct technology, applied in the direction of refrigerators, refrigeration and liquefaction, compressors with cascading work, etc., can solve the problem of low temperature for cold rooms, high pressure of refrigeration compressors, and failure of refrigeration compressors to work normally etc. to reduce power consumption, save energy, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the three-stage cascade direct-contact condensation refrigeration cycle system of the present invention includes a condenser 1, a high-temperature refrigeration compressor 2, a medium-temperature direct-contact heat exchanger 3, a medium-temperature circulation pump 4, a medium-temperature refrigeration compressor 5, and a low-temperature direct-contact heat exchanger. Heater 6, low temperature circulation pump 7, low temperature refrigeration compressor 8, evaporator 9, low temperature expansion valve 10, low temperature subcooler 11, medium temperature expansion valve 12, medium temperature subcooler 13, high temperature expansion valve 14;

[0014] The outlet of the evaporator 9 is connected to the inlet of the low-temperature refrigeration compressor 8, and the exhaust outlet of the low-temperature r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap