Method for preparing novel ZnO/Se/SiO2 composite material and application thereof in preparation of phthalide

A composite material, phthalide technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

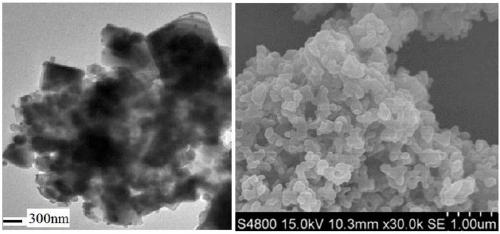

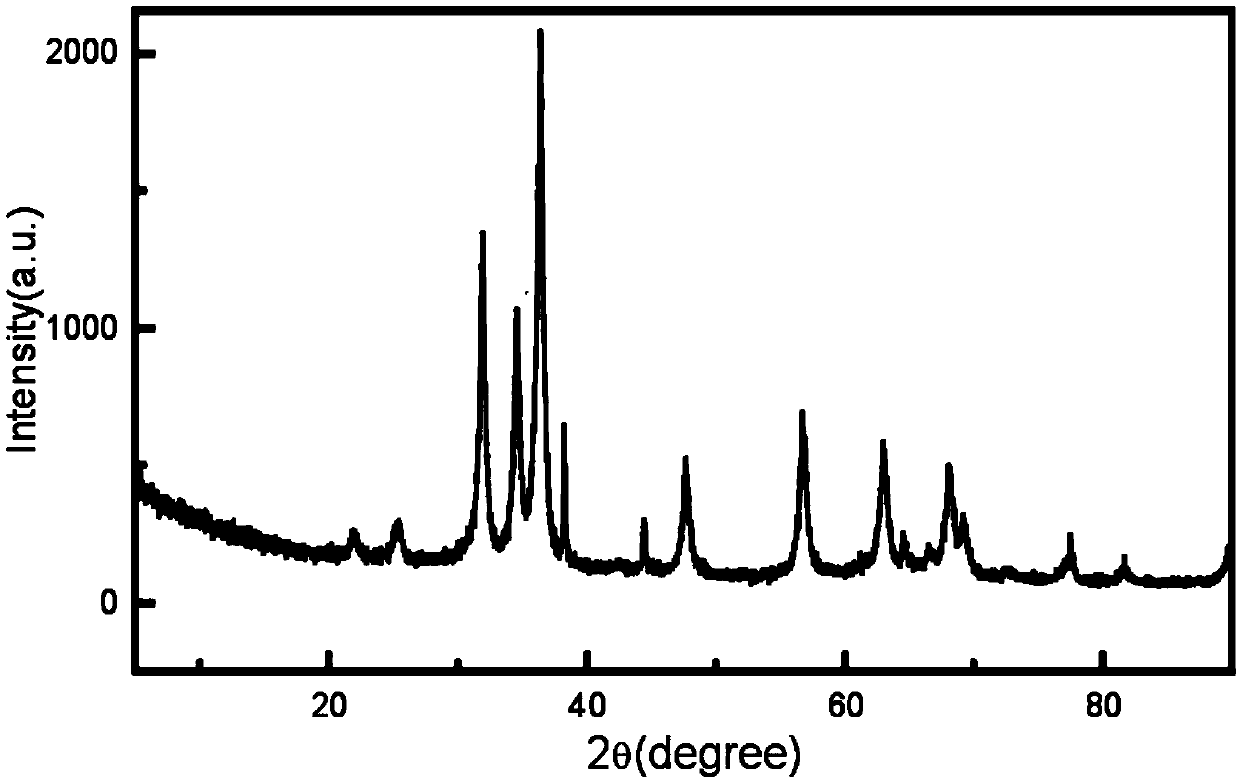

[0014] At room temperature, under stirring, add selenium-containing hydrazine hydrate (10 mL, containing 100 mg selenium) to the zinc nitrate solution (0.1 mmol / mL, 100 mL), continue stirring for 20 min, then raise the temperature to 170 ° C (autoclave) and react for 12 h. After naturally cooling to 90°C, add tetraethyl orthosilicate (1.5mL), continue to stir until naturally cooling to room temperature, filter and precipitate, wash with deionized water, absolute ethanol in turn, and vacuum dry to obtain the ZnO / Se / SiO 2 Composite material (hereinafter referred to as product A, figure 1 , 2 ).

Embodiment 2

[0016] At room temperature, under stirring, add selenium-containing hydrazine hydrate (30 mL, containing 180 mg selenium) to the zinc nitrate solution (0.2 mmol / mL, 100 mL), continue stirring for 30 min, then raise the temperature to 180 ° C (autoclave) and react for 8 h. After natural cooling to 90°C, add tetraethyl orthosilicate (4.0 mL), continue to stir until natural cooling to room temperature, filter, precipitate, wash with deionized water, absolute ethanol in turn, and vacuum dry to obtain the ZnO / Se / SiO 2 Composite material (hereinafter referred to as product B, the SEM image is consistent with product A).

Embodiment 3

[0018] At room temperature, under stirring, add selenium-containing hydrazine hydrate (10 mL, containing 100 mg selenium) to the zinc nitrate solution (0.1 mmol / mL, 100 mL), continue stirring for 20 min, then raise the temperature to 170 ° C (autoclave) and react for 12 h. Naturally cool to room temperature, filter, precipitate, wash with deionized water, absolute ethanol, and vacuum dry to obtain the ZnO / Se composite material (hereinafter referred to as product C).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap