Phase change heat storage device

A phase-change heat storage and hot water technology, which is applied in heat storage equipment, heat storage heaters, fluid heaters, etc., can solve the problems of insignificant enhancement of heat transfer effect, heavy material weight, stratification or settlement, etc. Light weight, good heat storage performance and low supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

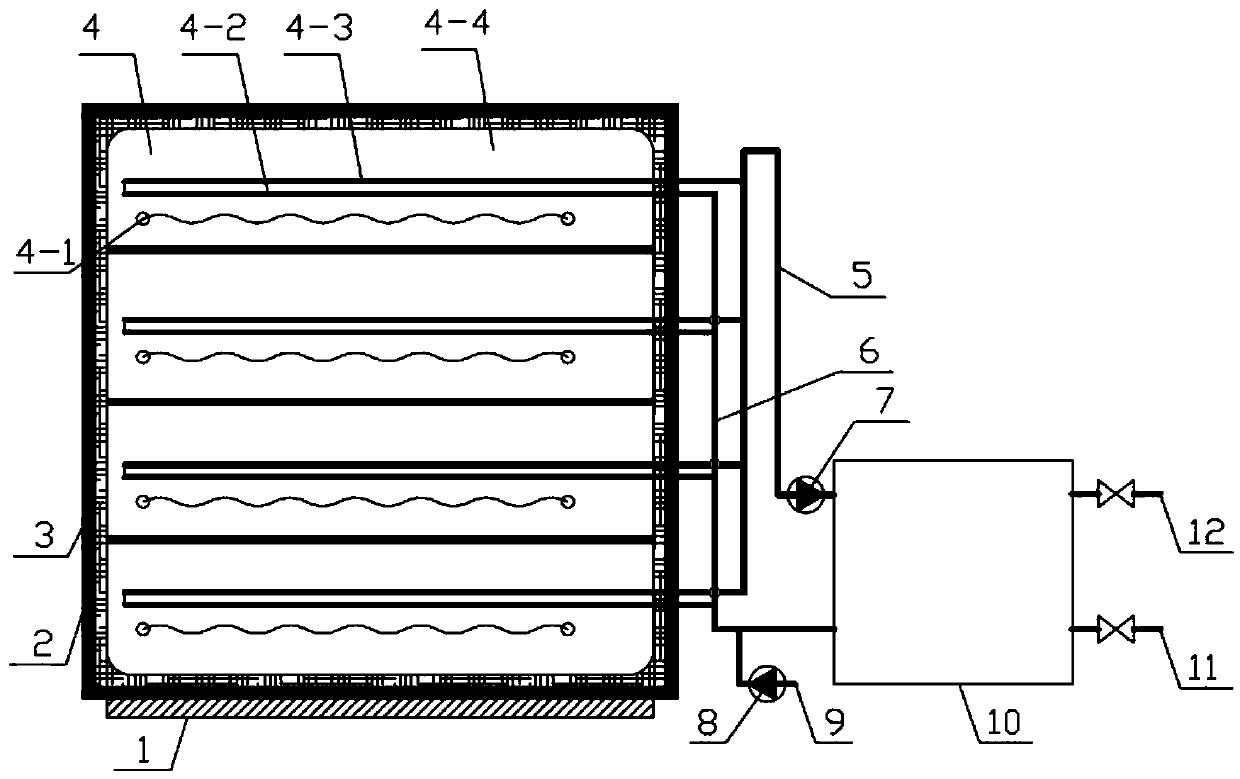

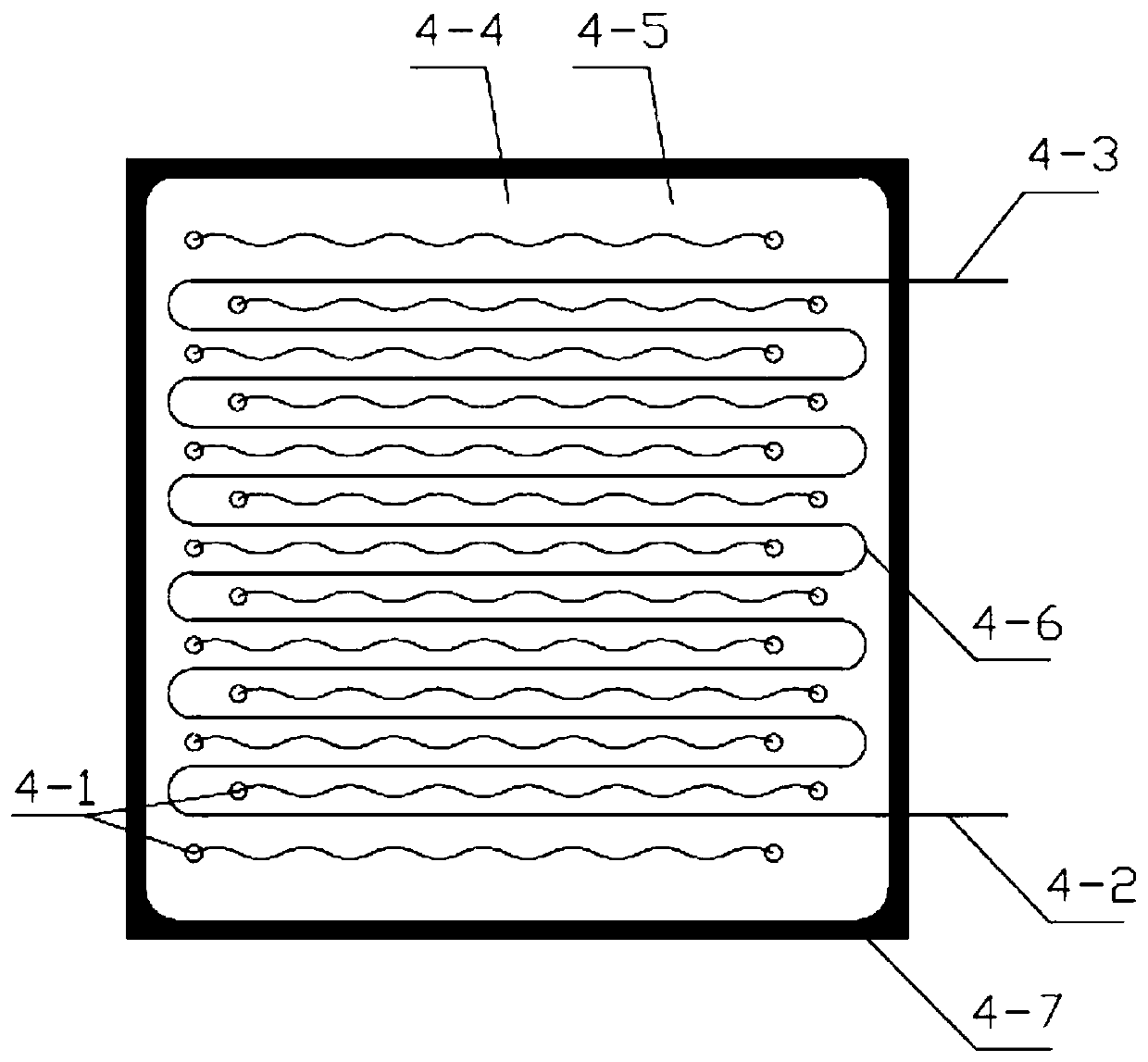

[0021] Such as Figure 1~2 As shown, the phase change heat storage device of the present invention includes a base 1 and a metal shell 2 fixed on the base 1. The inner side wall of the metal shell 2 is covered with an insulation layer 3, and several insulation layers 3 are arranged in parallel along the longitudinal direction. Phase change heat storage modules 4, each phase change heat storage module 4 is stacked up and down, the upper and lower surfaces of adjacent phase change heat storage modules 4 are attached to each other, and each phase change heat storage module 4 is placed directly or through a slot In the thermal insulation layer 3; the phase change heat storage module 4 includes a metal frame 4-7, a metal foam 4-5 evenly filled in the closed metal frame 4-7, and a phase change material 4 evenly filled in the metal foam 4-5 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap