Trimming mold used for car rear wall outside plate

A technology for trimming molds and peripheral panels, applied in the field of auto parts processing, can solve problems such as safety hazards, thread breakage, fatigue loss, etc., and achieve the effects of easy replacement and maintenance, prolonging service life, and avoiding fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

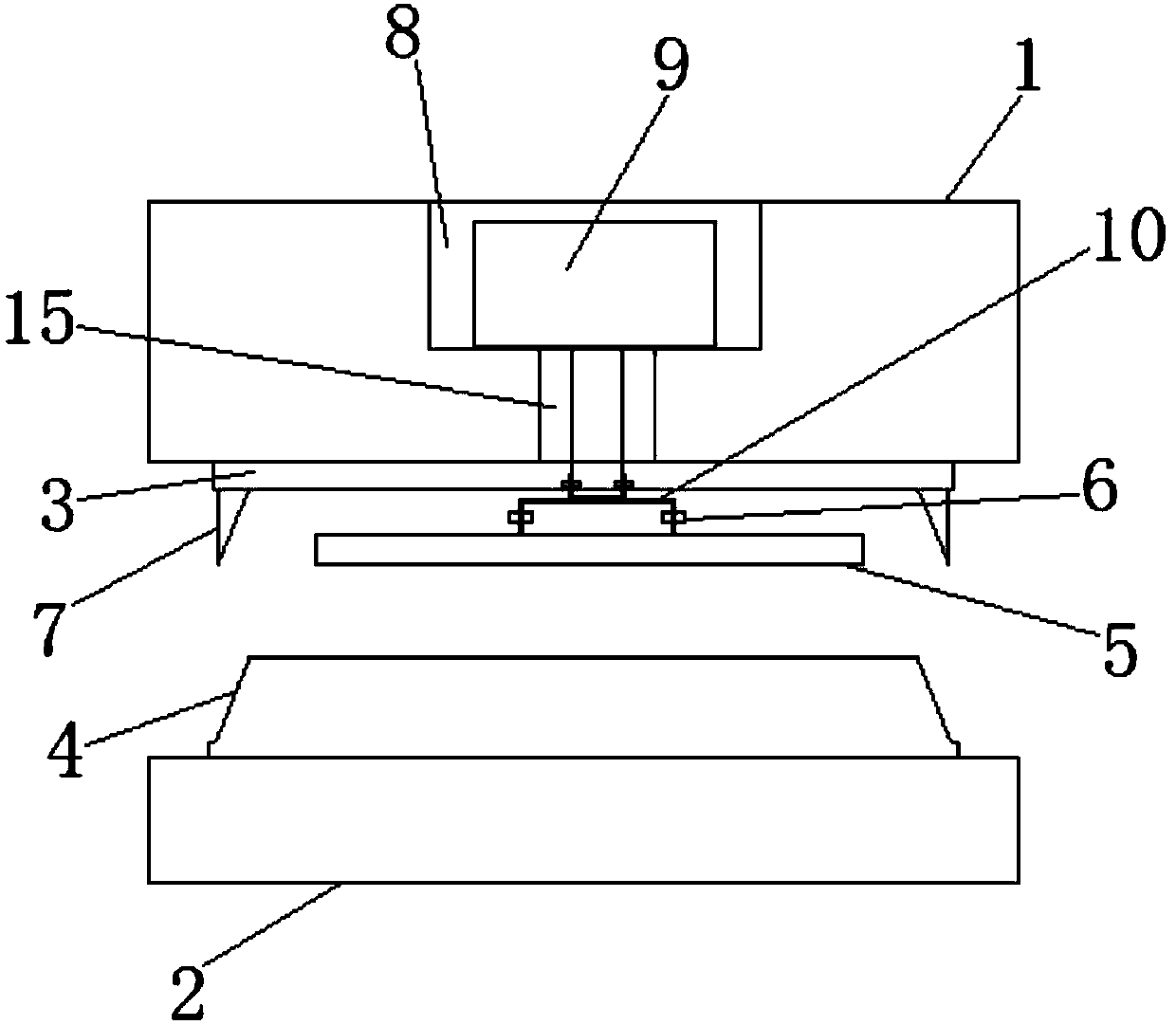

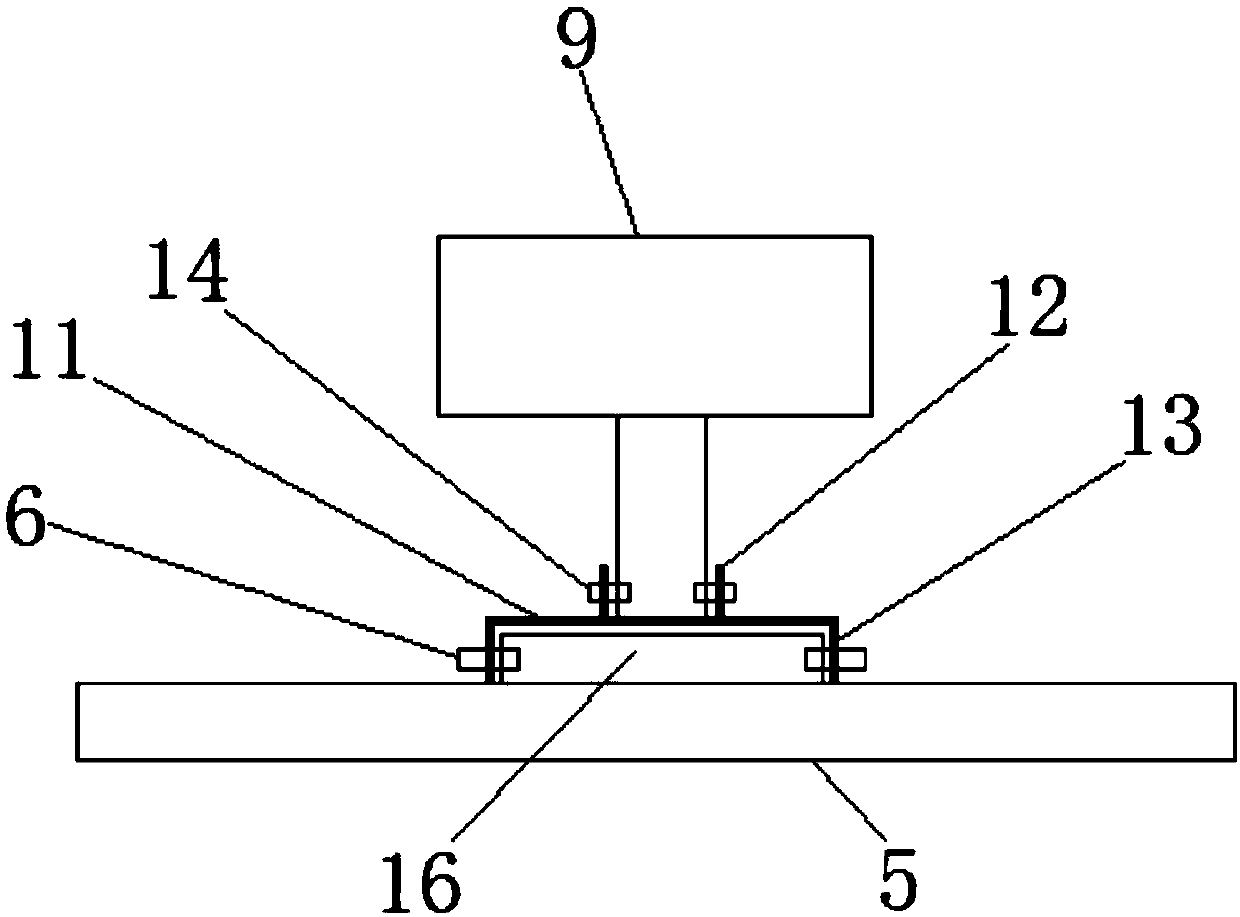

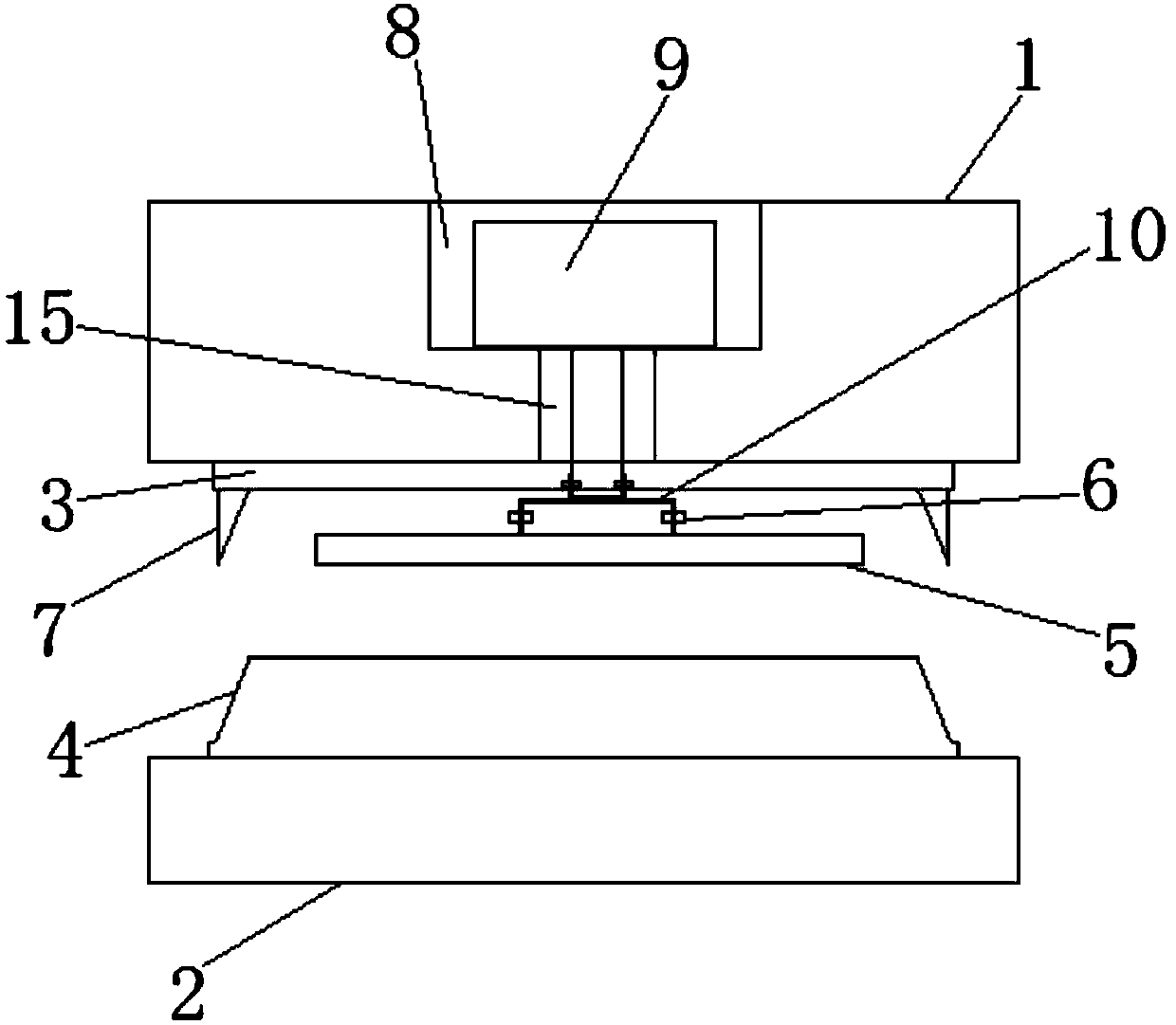

[0024] Such as figure 1 Shown is a trimming mold for the rear panel of an automobile, the mold includes an upper mold base 1 and a lower mold base 2 that is compatible with the upper mold base 1, and an upper mold base 1 is provided on the lower surface of the upper mold base 1. Die trimming insert 3, the lower die base 2 is provided with the lower die trimming insert 4 that matches with upper die trimming insert 3, and mold also includes moving along the vertical direction and is arranged on the upper die base 1 and the lower die base. The binder plate 5 between the mold bases 2 and the binder plate drive mechanism connected with the binder plate 5 transmission, the binder plate connecting pin 6 is provided along the horizontal direction between the binder plate 5 and the binder plate drive mechanism, and It is fixedly connected to the driving mechanism of the pressing plate through the connecting pin 6 of the pressing plate.

[0025] Wherein, the upper mold trimming insert 3 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap