Heat dissipation system for battery pack of new energy automobile

A new energy vehicle and heat dissipation system technology, applied in the field of new energy vehicle battery pack heat dissipation system, can solve the problems of reduced service life of power battery, poor heat dissipation effect, difficult disassembly, etc., and achieve the effect of improving heat dissipation efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

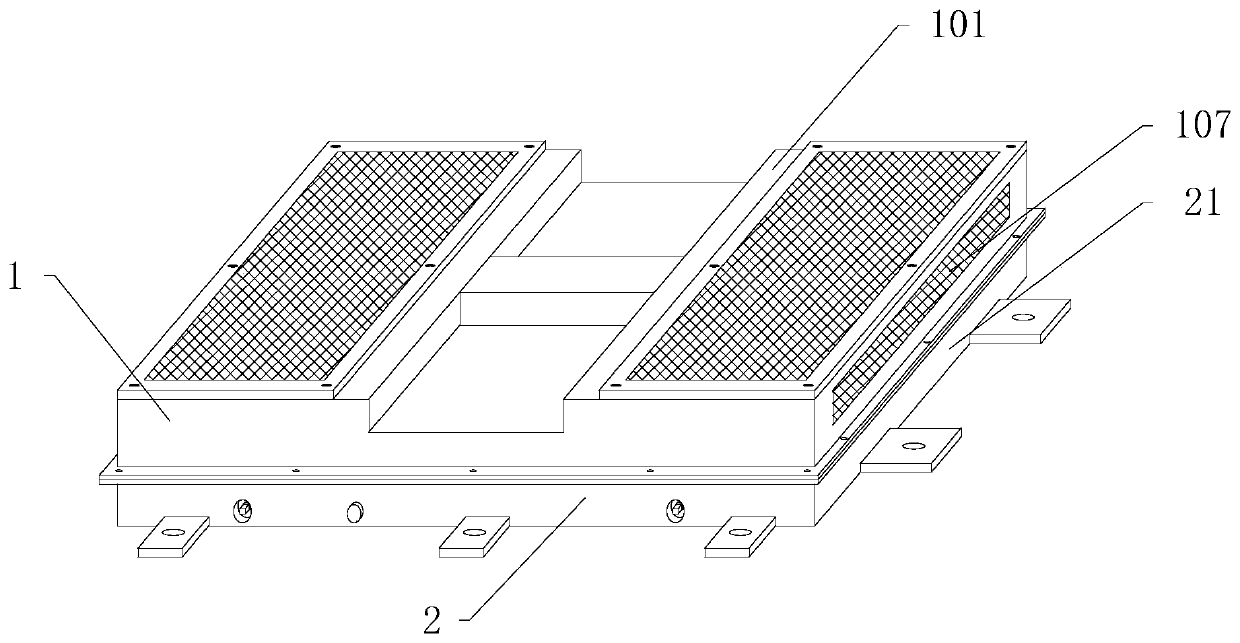

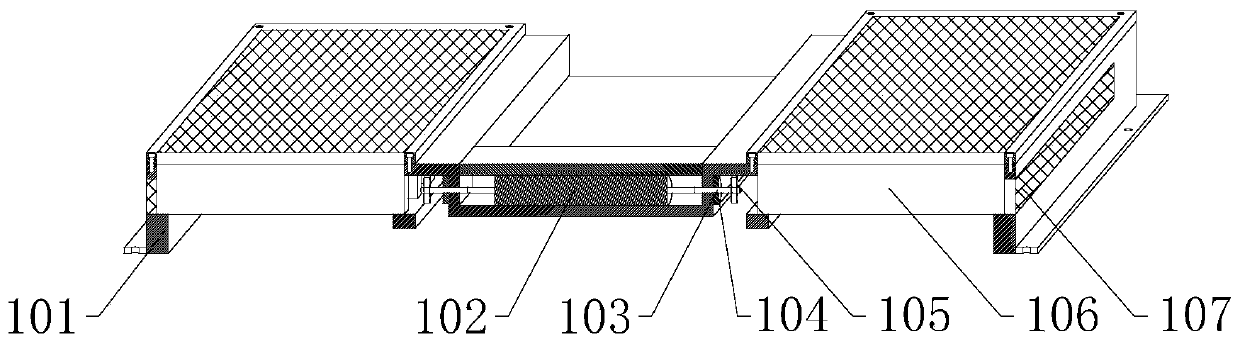

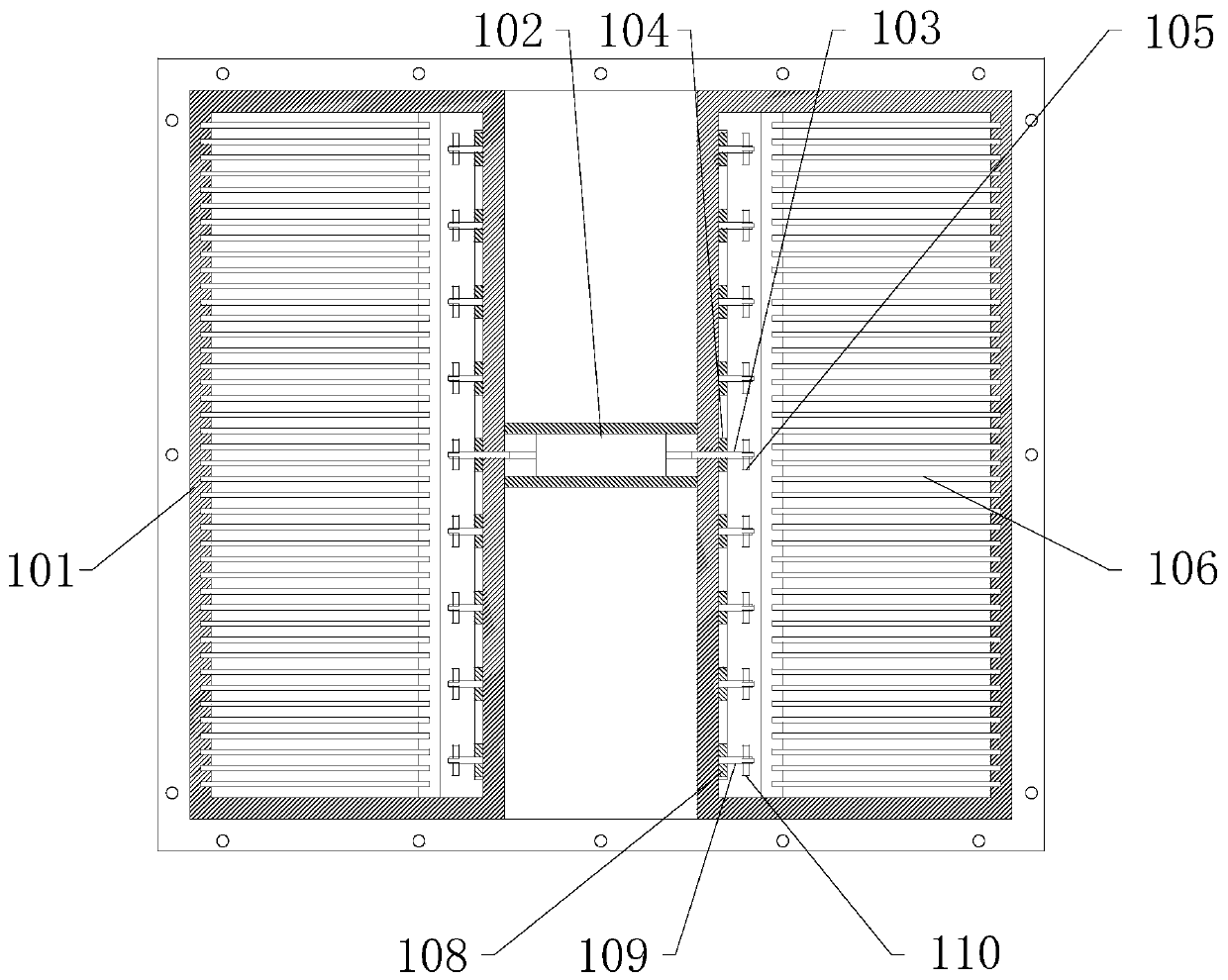

[0022] See Figure 1-Figure 6 , The present invention provides a technical solution: a new energy vehicle battery pack heat dissipation system, including a heat dissipation mechanism 1 and an auxiliary mechanism 2. The heat dissipation mechanism 1 has an auxiliary mechanism 2 installed at the lower end, and the heat dissipation mechanism 1 includes an upper shell 101, a double-head motor 102, The main shaft 103, the pulley one 104, the fan blade 105, the heat sink 106, the cooling net 107, the pulley two 108, the auxiliary shaft 109 and the fan blade two 110, the auxiliary mechanism 2 includes a lower shell 21, a bottom plate 22, a through groove 23, and a rotating shaft 24 and a curved single lever 25.

[0023] As an embodiment of the present invention: in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap