Biomass continuous depolymerization device and method capable of taking materials on line

A biomass and feed technology, which is applied to the chemical industry technical equipment and energy fields of biomass, can solve the problems that affect the industrialization of continuous reaction devices, easily generate a large number of by-products, and be difficult to reclaim materials online. The effect of hydrolysis efficiency and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

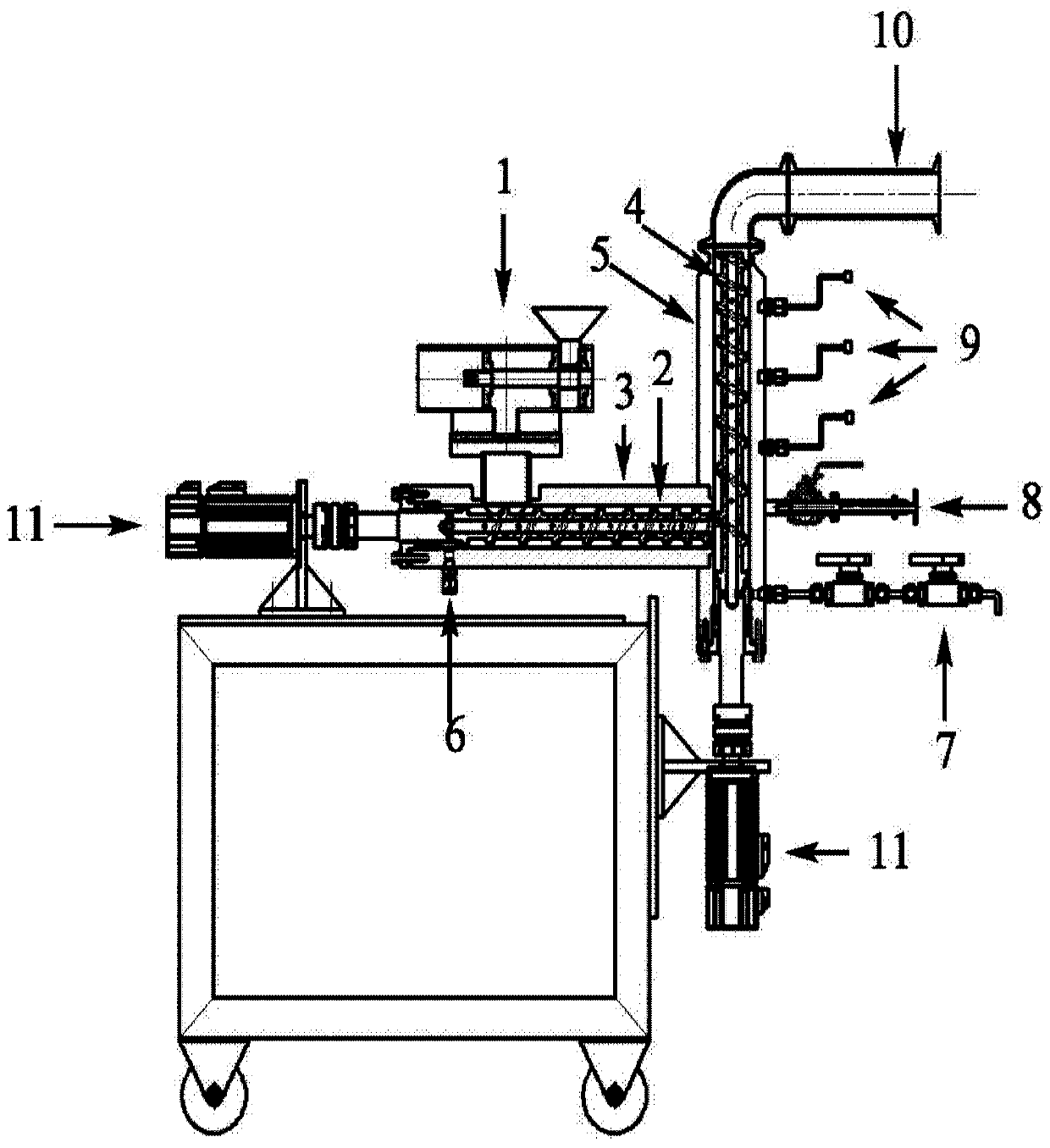

[0109] Such as figure 1 As shown, a biomass continuous depolymerization device capable of online reclaiming includes a pressurized feeding system, a reaction system, an online reclaiming system, and a reactant collector. Specifically include: reciprocating pressurized feeding system 1, equal pitch screw (first screw) 2, horizontal reactor (first reactor) 3, variable pitch hollow screw (second screw) 4, vertical reactor ( Second reactor) 5, catalyst feed port 6, hydrolyzate outlet 7, solid sampling port 8, sensor 9, residue outlet 10, power motor (power unit) 11.

[0110] Taking corn stalks as raw materials as an example, the crushed corn stalks are transported to the horizontal reactor 3 through the reciprocating pressurized feeding system 1, and at the same time, the high-temperature steam carries the acid liquid through the catalyst feed port 6 and the equal-pitch screw 2 to enter the reaction. Mix with the solid material in the container, and push it under the push of equal-p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap