Clamping jaw structure for automobile engine cylinder body or cylinder cover

A technology for automobile engines and grippers, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of single grasping position, unstable grasping parts, etc., and achieve small size, high work efficiency and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

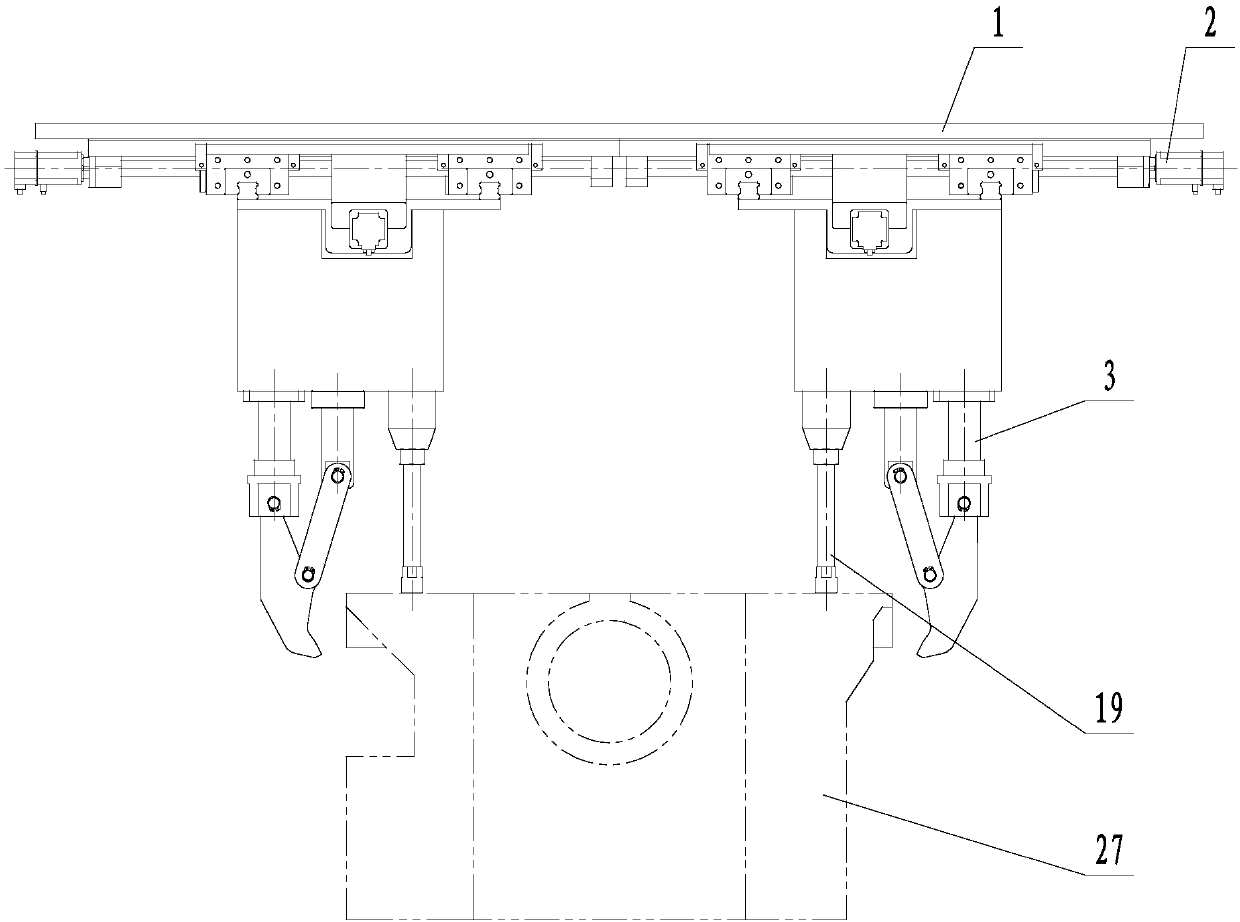

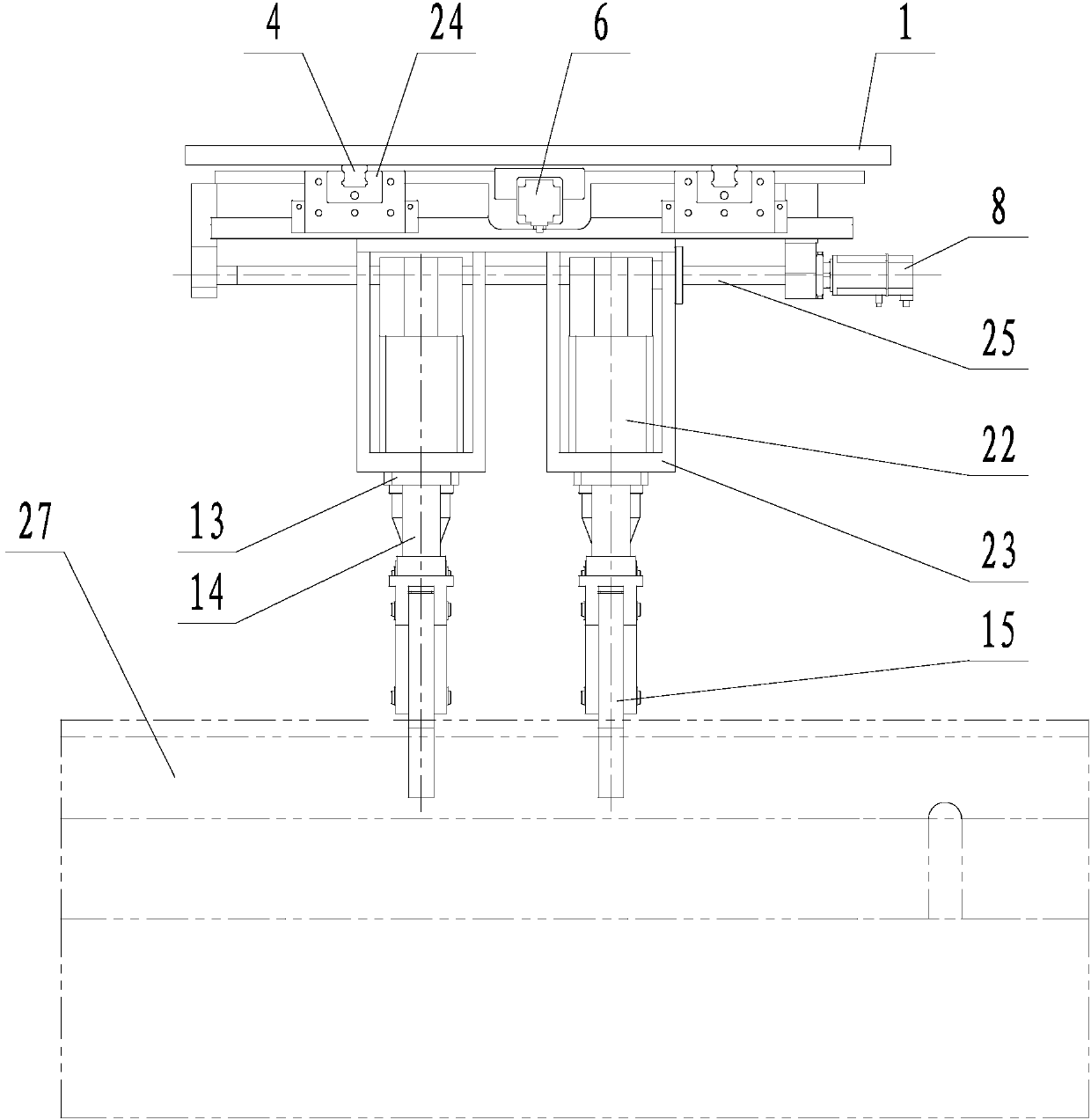

[0024] Such as Figure 1~5 As shown, the present invention includes a mounting plate 1, an X—Z sliding table 2 and at least one set of jaw devices 3, wherein the jaw device 3 is installed on the mounting plate 1 through the X—Z sliding table 2, and the jaw device 3 has the degree of freedom of reciprocating movement along the X-axis and Z-axis perpendicular to each other in the X-Z slide table 2. Two gripper devices 3 form a group. The gripper devices 3 in this implementation are divided into two groups and four. The gripper devices 3 on the same side in each group share one X—Z slide table 2 and are installed on the mounting plate 1. . A set of two gripper devices 3 are respectively located on both sides of the cylinder body or cylinder head, and the gripper devices 3 on each side are respectively installed on the mounting plate 1 through their own X—Z slidin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap