Rotary lifting structure and moving van

A technology of rotating barrels and rotating wheels, which is applied in the direction of lifting devices, transmission devices, belts/chains/gears, etc., can solve the problems of inability to achieve lifting or rotation alone, poor stability and reliability, and inconvenient maintenance, and achieve the operation process. Easier to monitor, easier to maintain and service, easier to monitor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

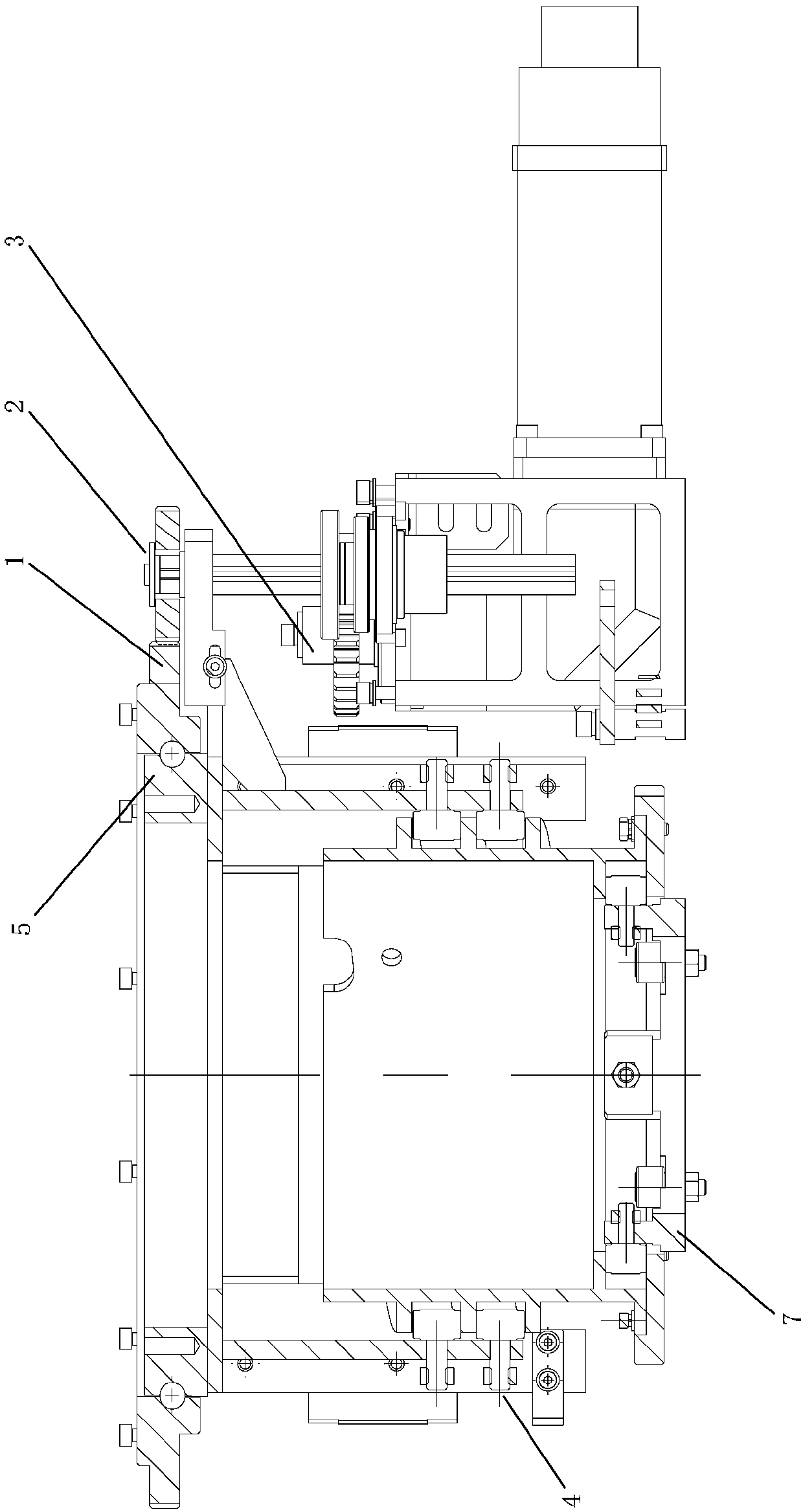

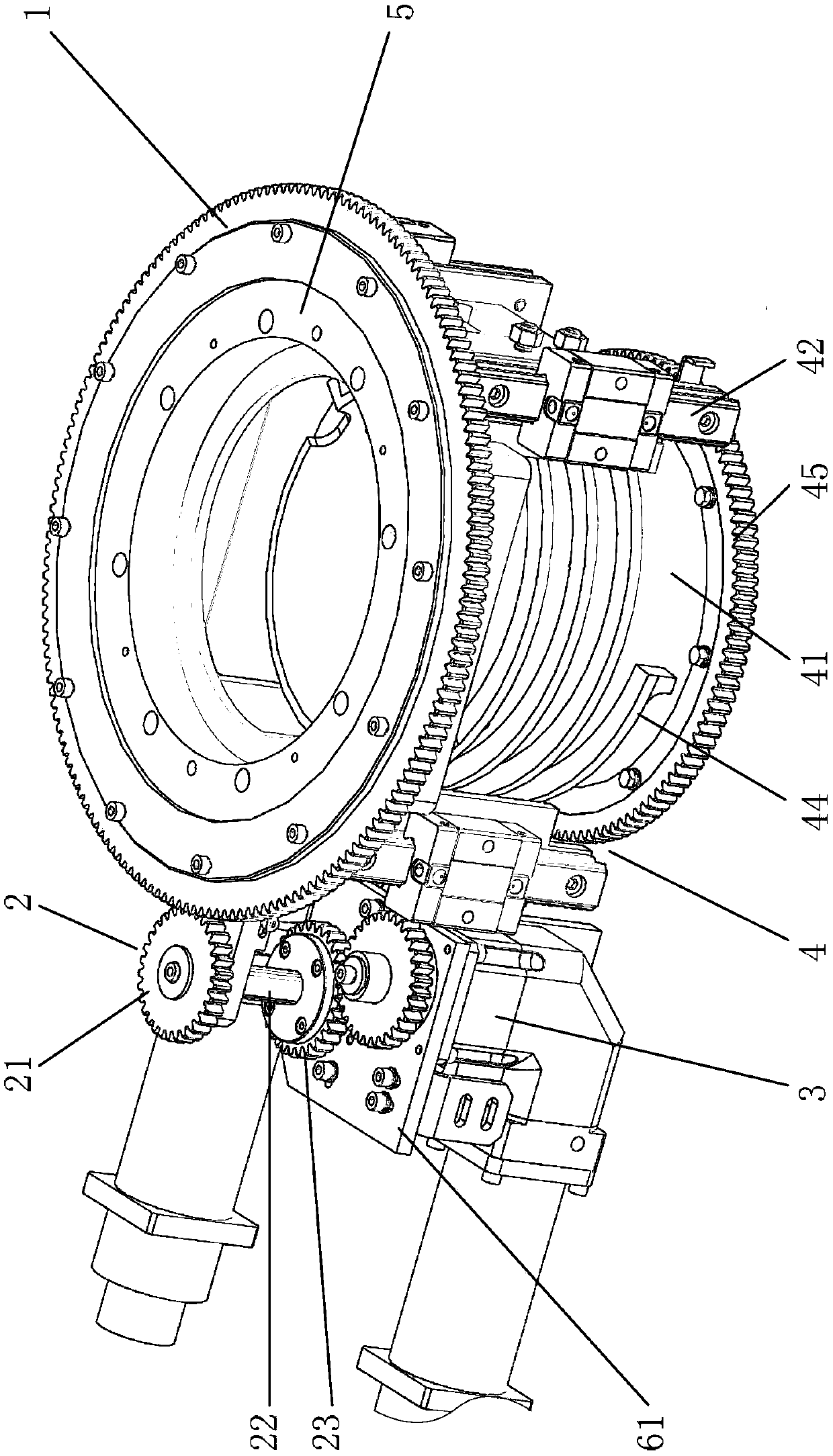

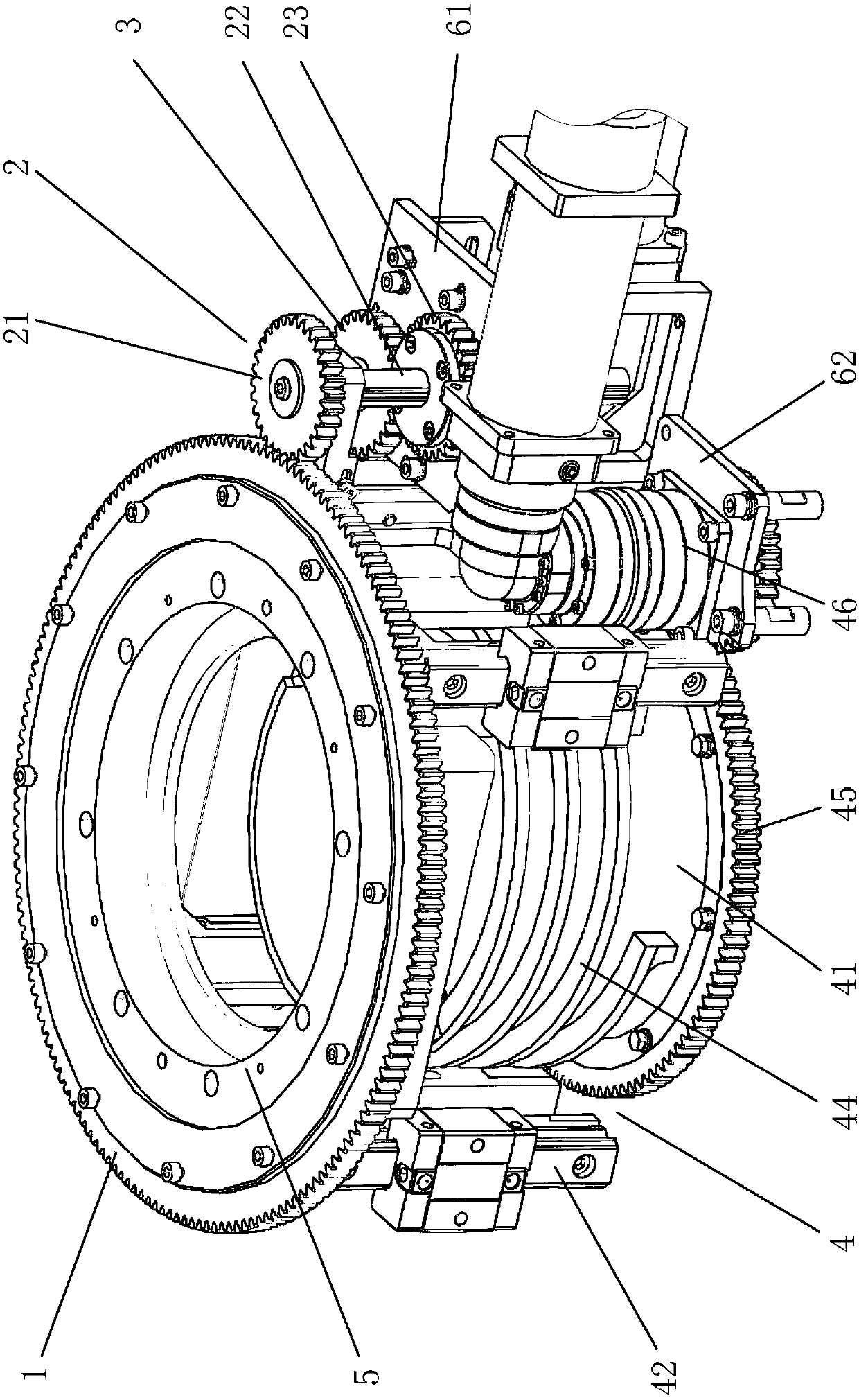

[0037] figure 1 It is a schematic diagram of a rotary lifting structure provided by an embodiment of the present invention.

[0038] Such as figure 1 As shown, a rotary lifting structure provided by the embodiment of the present invention mainly includes: a rotary wheel 1 , a spline shaft drive train 2 , a rotary power assembly 3 , and a lifting part 4 that drives the ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap