Smelting device for rare-earth metal production with function of tail gas treatment

A technology of tail gas treatment and rare earth metals, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient maintenance of the flue gas collection part, cannot adapt to large-scale production, etc., and achieves convenient maintenance and maintenance , improve the service life, improve the effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

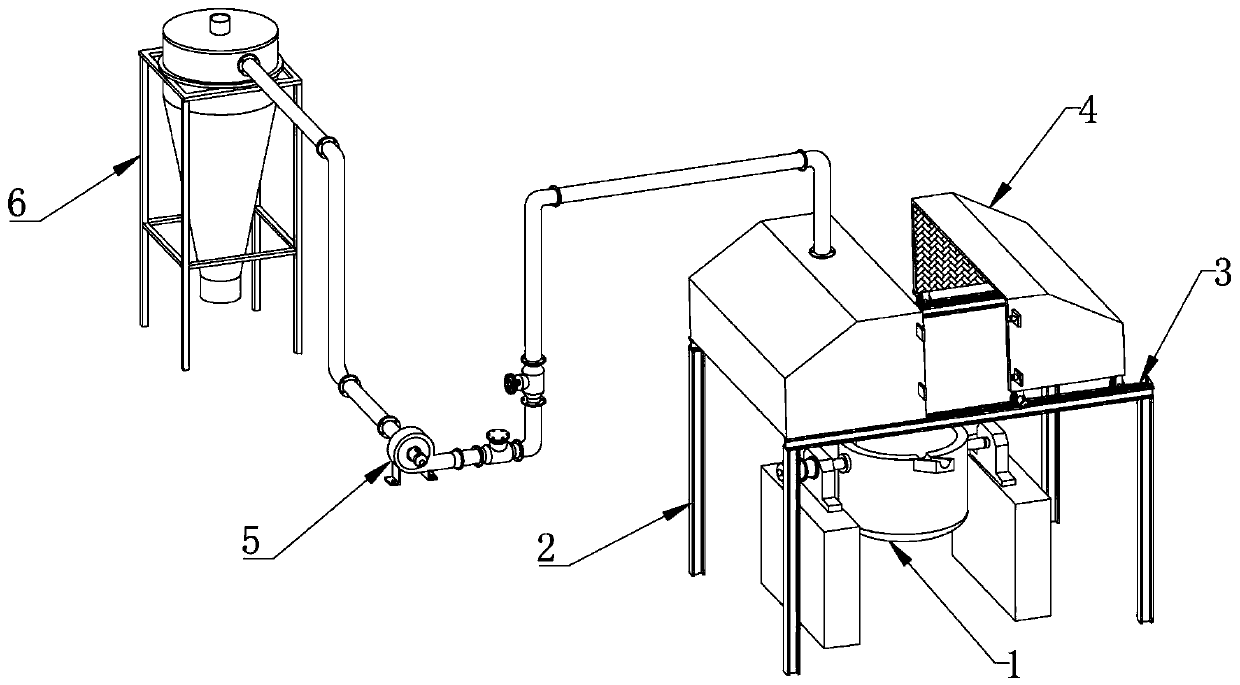

[0021] See Figure 1 ~ Figure 4 In the embodiment of the present invention, a smelting equipment with tail gas treatment for the production of rare earth metals includes an electric furnace 1 and a set of door frames 2 arranged in parallel on the outer side of the top end of the electric furnace 1, and one side of the top end of the door frame 2 is fixedly connected There is a set of guide rails 3, the top of the door frame 2 and the guide rail 3 are jointly provided with a smoke hood 4, the top side of the smoke hood 4 is fixedly connected with a fan assembly 5, and the output end of the fan assembly 5 is fixedly connected with a cyclone dust collector 6.

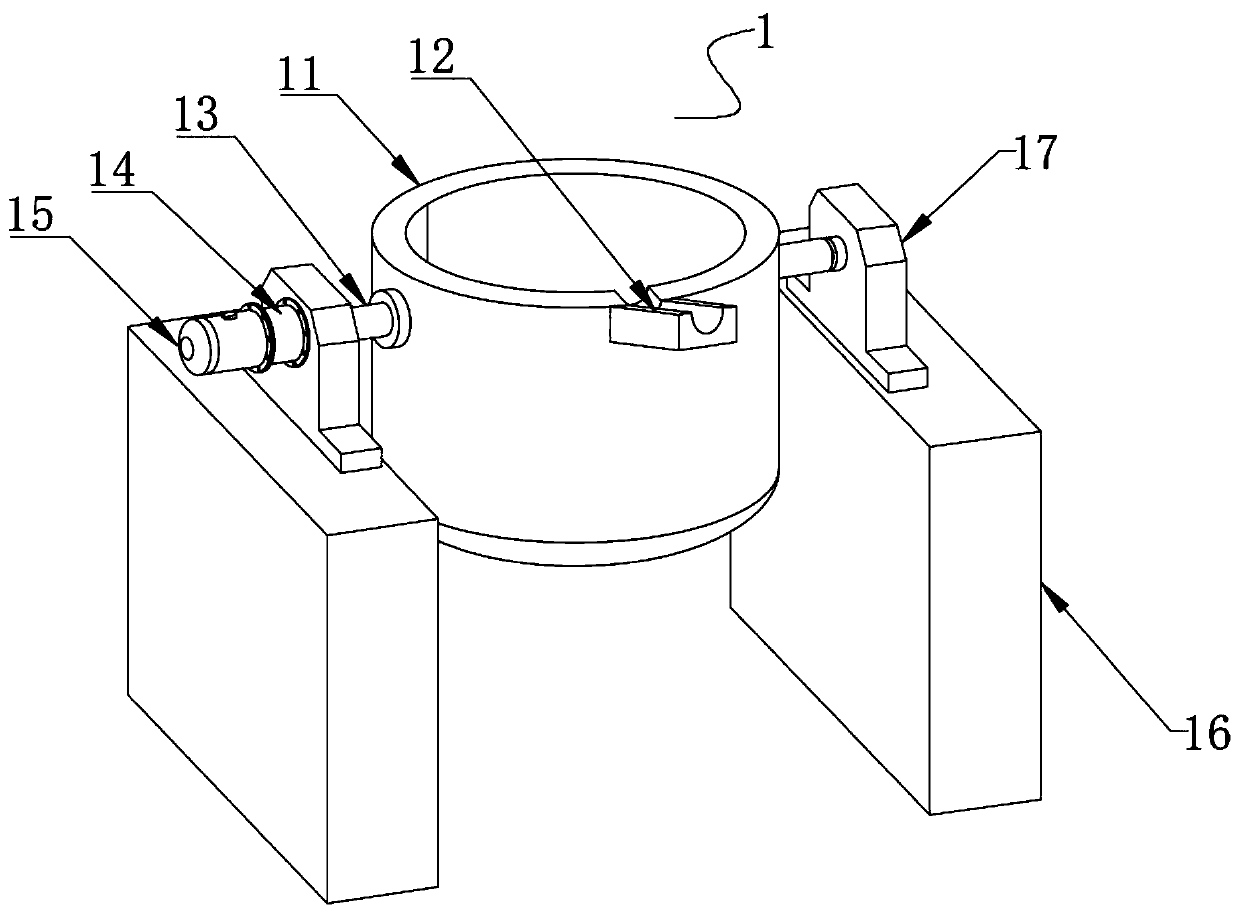

[0022] in figure 2 Middle: The electric furnace 1 includes a furnace body 11, both ends of the outer side of the furnace body 11 are fixedly connected with a trunnion 13, the upper end of the outer side of the furnace body 11 is provided with a discharge port 12, and the outer end of the trunnion 13 is rotatably connected with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap