Fiber grating sensor capable of measuring temperature and pressure simultaneously and measurement method

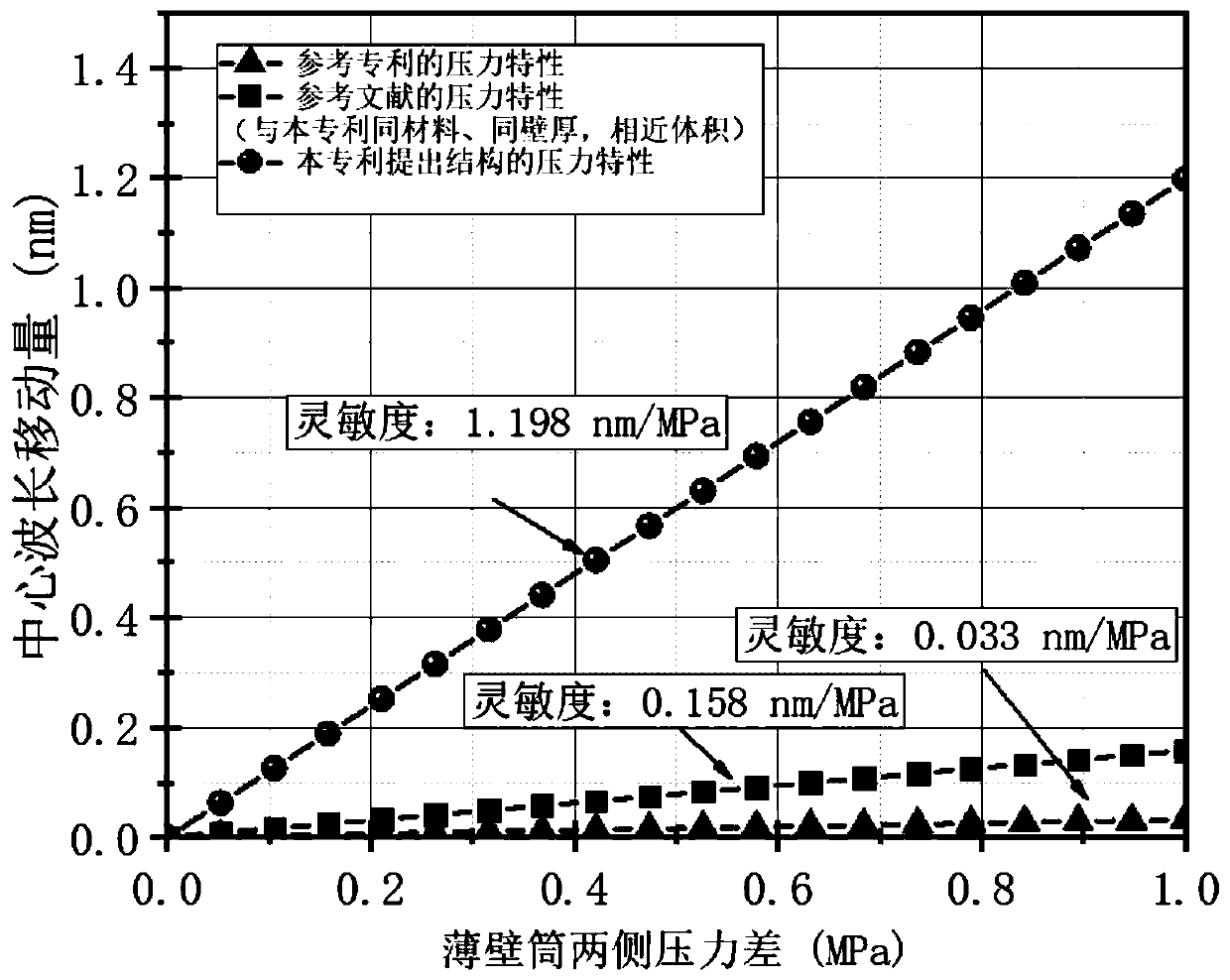

A fiber grating and temperature measurement technology, which is applied in the direction of measuring fluid pressure, measuring devices, fluid pressure measurement using optical methods, etc., can solve the problem that temperature-compensated gratings are easily disturbed by external temperature, long decoupling response time, and cannot meet the needs To achieve the effect of solving the problem of temperature cross-sensitivity, improving environmental adaptability, improving temperature consistency and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

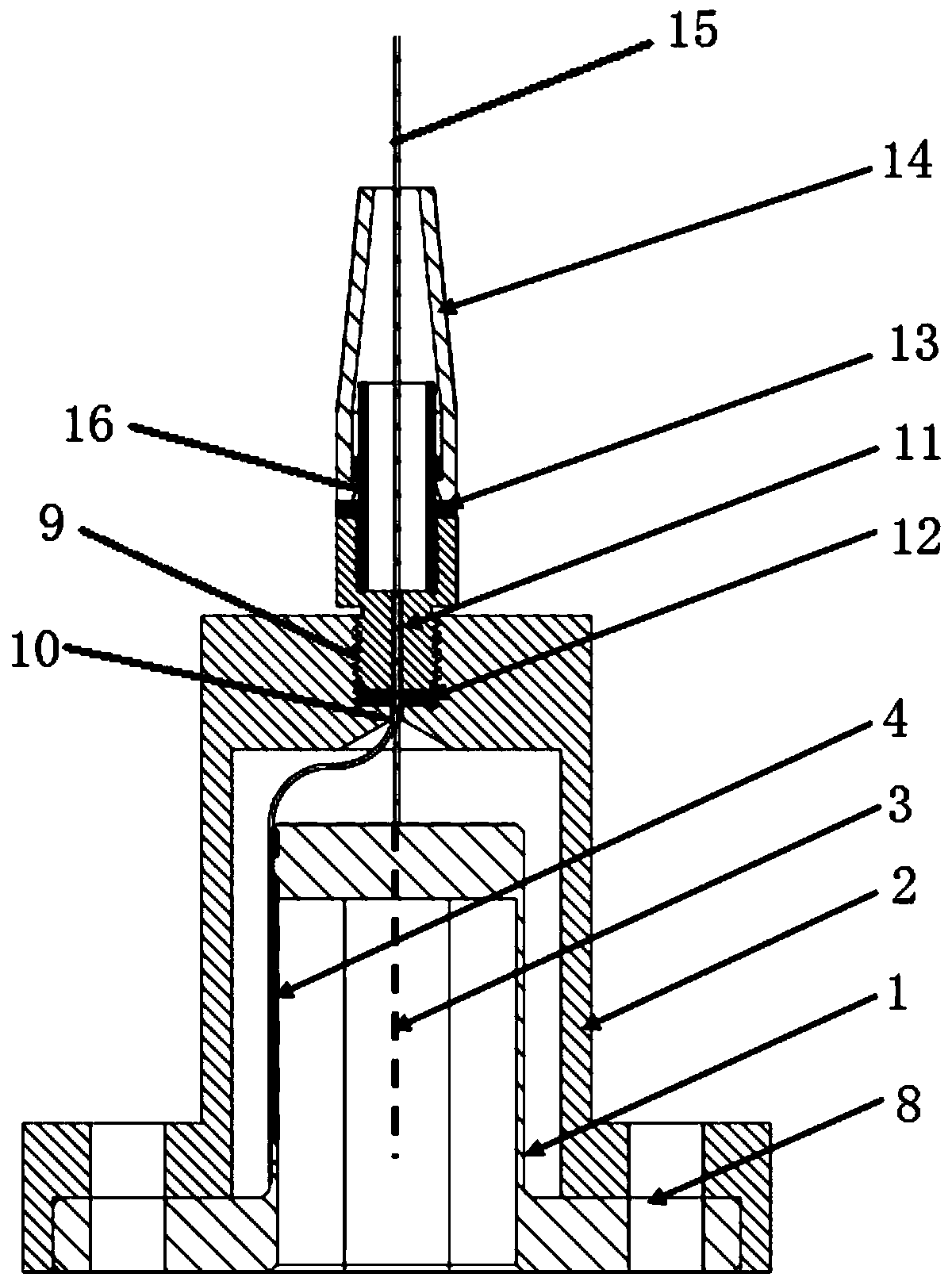

[0031] The invention provides a fiber grating sensor capable of simultaneously measuring temperature and pressure, such as figure 1 As shown in the structure, the sensor has a novel structure, high sensitivity, fast temperature decoupling response, and more accurate measurement results.

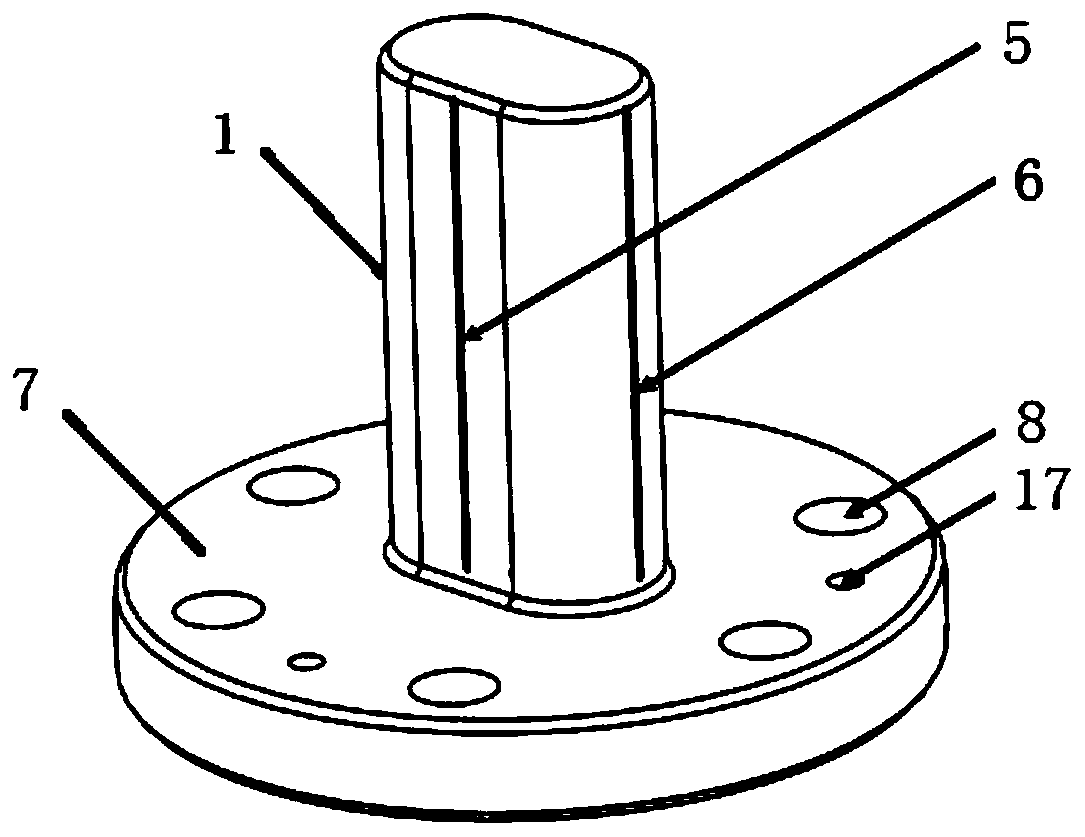

[0032] Such as figure 1 A fiber grating sensor capable of simultaneously measuring temperature and pressure is shown, comprising a thin-walled tube 1 with an open bottom, a protective shell 2 packaged outside the thin-walled tube 1, and there is a gap between the thin-walled tube 1 and the protective shell 2; A first fiber grating 3 and a second fiber grating 4 are fixed on the outer surface of the thin-walled tube 1 , and the fiber pigtails 15 of the first fiber grating 3 and the second fiber

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap