Preparation method of high-yield silver nanowire

A nano-silver wire, high-yield technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the impact of the production of nano-silver wire, incomplete reaction of nano-silver wire, and limited multiple Promote the promotion of alcohol method and other issues, achieve the effect of strong reducibility, cost saving and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

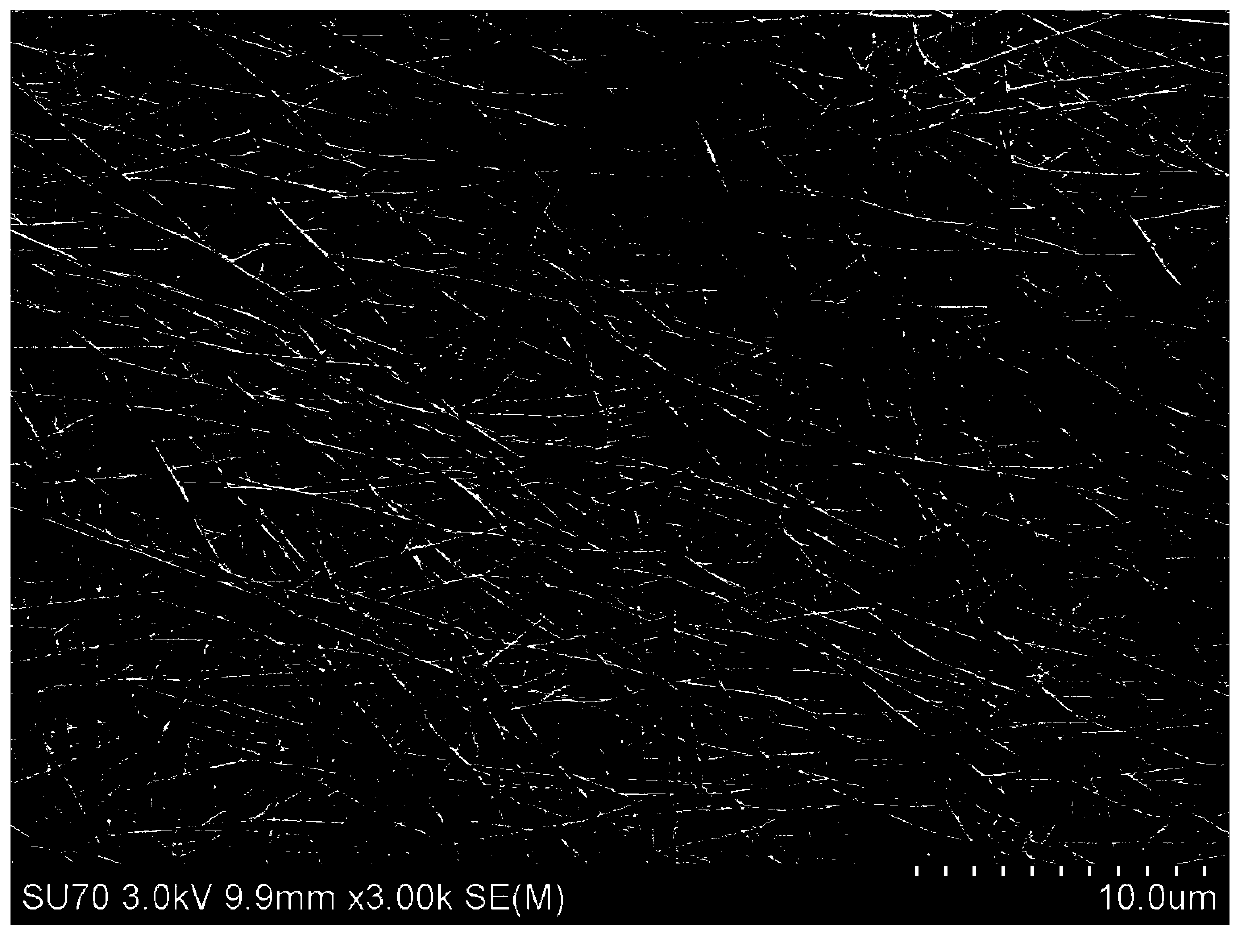

[0034] Example 1

[0035] A method for preparing high-yield nano silver wires includes the following steps:

[0036] 1) Add 0.8g of PVP with a molecular weight of 40,000 and 0.8g of PVP with a molecular weight of 400,000 to the reaction vessel, then add 200mL of ethylene glycol solution, and place the reaction vessel containing the above solution in a thermostatic magnetic stirrer for stirring. The temperature is 140°C, the stirring speed is 150rpm, and the stirring time is 120min;

[0037] 2) Add 18 mL of ferric chloride ethylene glycol solution (0.0005g / mL) that has been stirred at room temperature for more than 120 minutes into the reaction vessel, and continue stirring for 30 minutes at a temperature of 140°C at a speed of 150 rpm;

[0038] 3) Subsequently, 24 mL of silver nitrate glycol solution (0.05g / mL) that has been stirred at room temperature for more than 30 minutes was added dropwise to the reaction vessel with a dropping rate of 0.5mL / min. After all the drops were comp

Example Embodiment

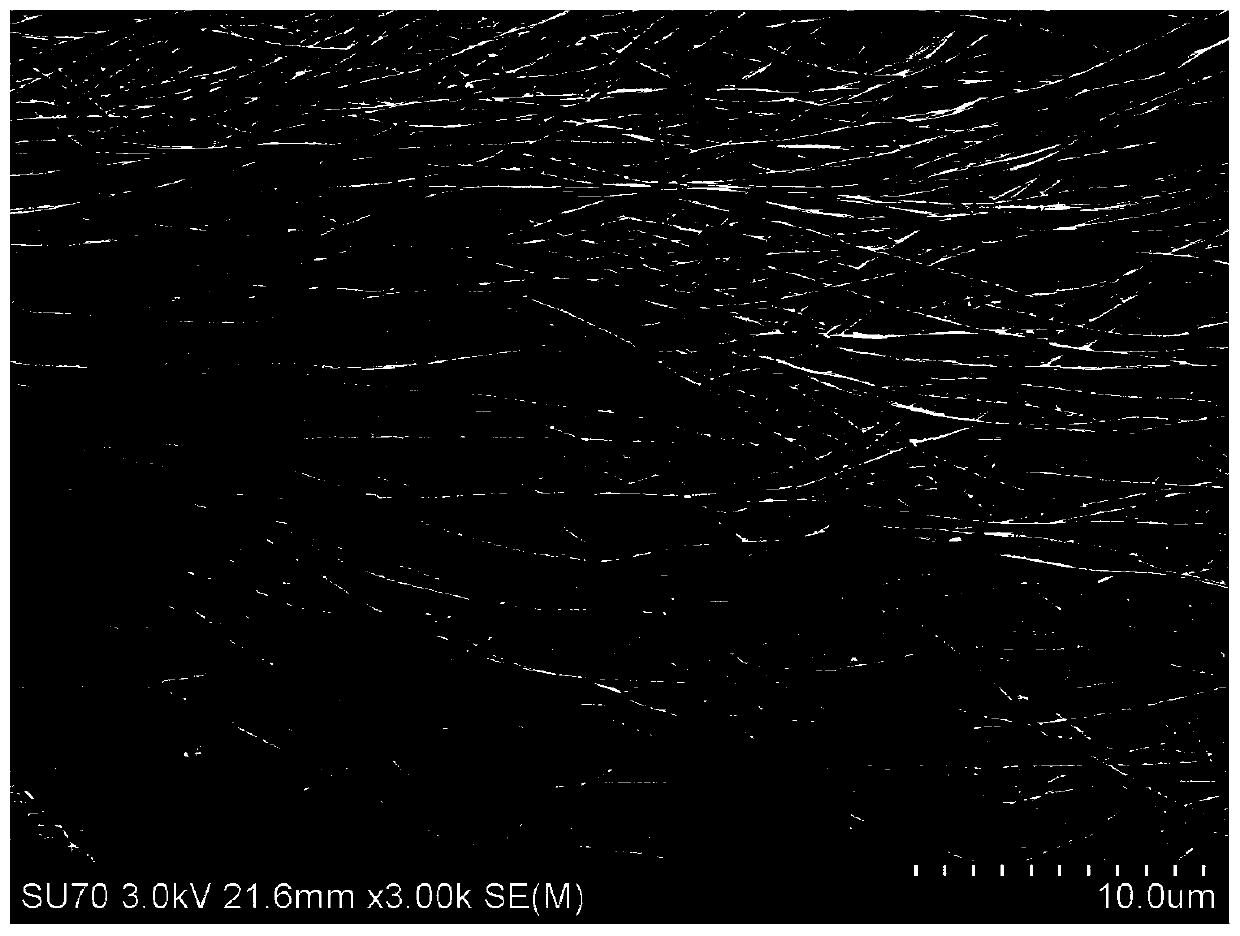

[0042] Example 2

[0043] A method for preparing high-yield nano silver wires includes the following steps:

[0044] 1) Add 0.8g of PVP with a molecular weight of 58,000 and 0.8g of PVP with a molecular weight of 240,000 to the reaction vessel, and then add 200mL of ethylene glycol solution, and place the reaction vessel containing the above solution in a thermostatic magnetic stirrer for stirring. The temperature is 140°C, the stirring speed is 350rpm, and the stirring time is 60min;

[0045] 2) Add 18 mL of ferric chloride ethylene glycol solution (0.0005g / mL) that has been stirred at room temperature for more than 120 minutes into the reaction vessel, and continue to stir for 30 minutes at a temperature of 140°C at a speed of 350 rpm;

[0046] 3) Subsequently, 24 mL of silver nitrate glycol solution (0.05g / mL) that has been stirred at room temperature for more than 30 minutes was added dropwise to the reaction vessel with a dropping rate of 0.5mL / min. After all the drops were co

Example Embodiment

[0050] Example 3

[0051] A method for preparing high-yield nano silver wires includes the following steps:

[0052] 1) Add 0.8g of PVP with a molecular weight of 40,000 and 0.8g of PVP with a molecular weight of 400,000 to the reaction vessel, then add 200mL of ethylene glycol solution, and place the reaction vessel containing the above solution in a thermostatic magnetic stirrer for stirring. The temperature is 170°C, the stirring speed is 200rpm, and the stirring time is 120min;

[0053] 2) Add 27mL of copper chloride glycol solution (0.0005g / mL) that has been stirred at room temperature for more than 120 minutes into the reaction vessel, and continue to stir for 30 minutes at a temperature of 170°C at a speed of 200rpm;

[0054] 3) Subsequently, 24mL of silver nitrate glycol solution (0.05g / mL) that has been stirred at room temperature for more than 30 minutes was added dropwise to the reaction vessel with a dropping rate of 1mL / min. After all the drops were completed, the grow

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap