Polyethylene plastic submerged material impurity removing system

A polyethylene plastic and impurity removal technology, applied in the field of polyethylene processing, can solve problems such as affecting the effect and difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

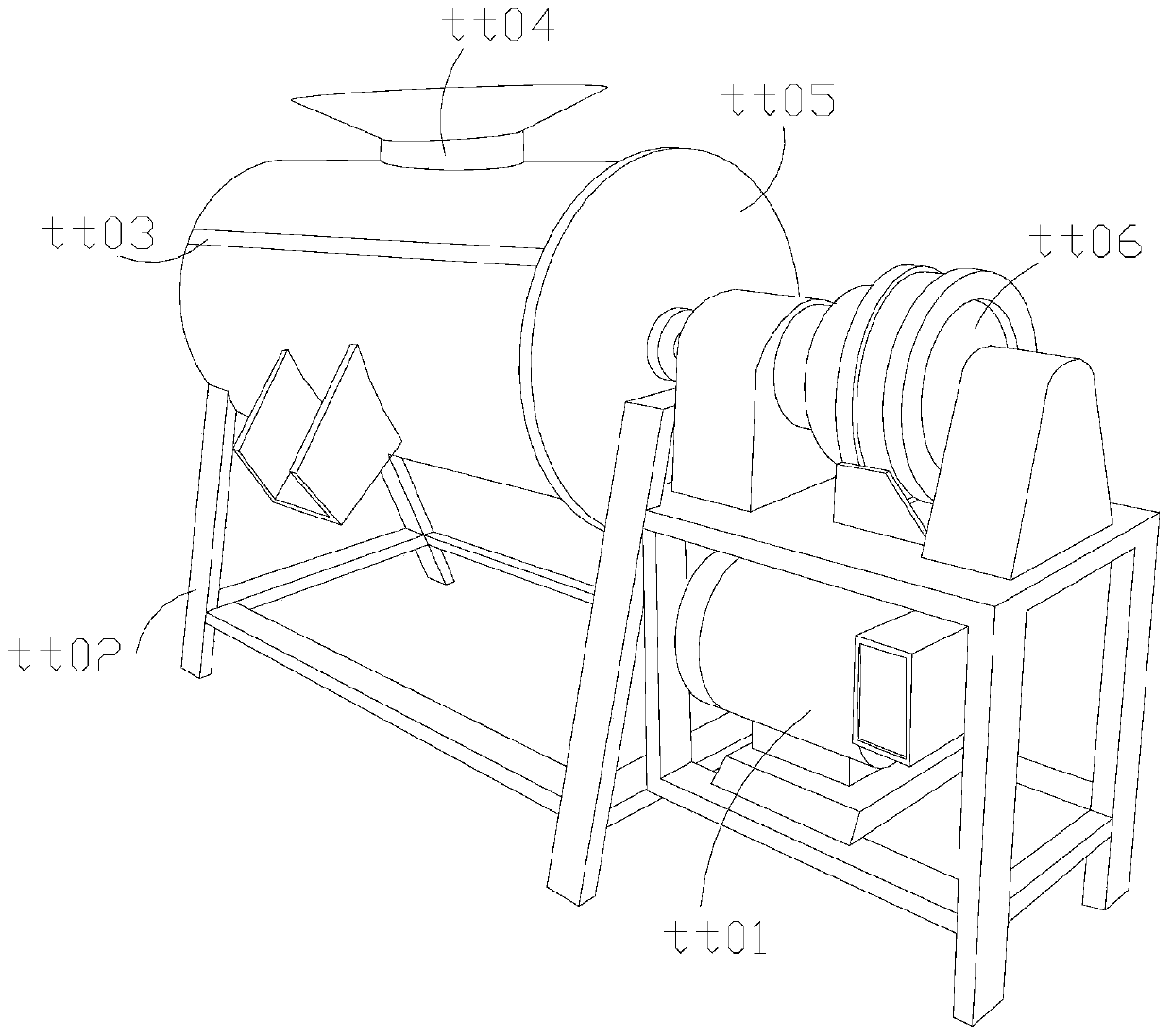

[0032] as attached figure 1 to attach Figure 5 Shown:

[0033] The invention provides a polyethylene plastic submerged material impurity removal system, the structure of which includes a main control machine tt01, a support leg tt02, a support filter layer tt03, an inlet tt04, a side guard plate tt05, and a main control wheel tt06.

[0034] The main control unit tt01 is connected to the main control wheel tt06 through wires, the support leg tt02 is welded to the lower surface of the filter layer tt03, the filter layer tt03 is connected with the insertion port tt04, and the main control wheel tt06 runs through the Inside the side guard tt05.

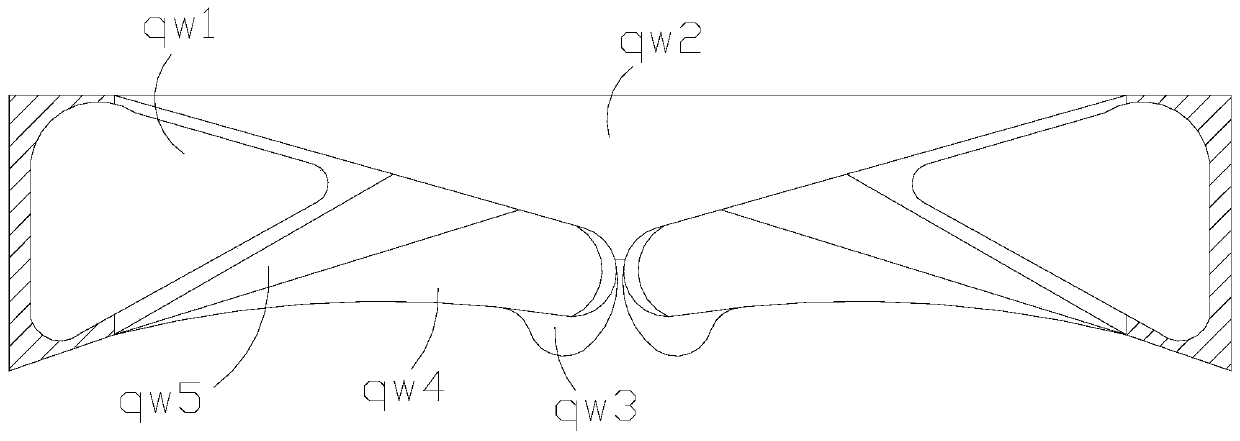

[0035] Wherein, the inlet tt04 includes a solid force angle qw1, an inclined opening qw2, a sticking head qw3, a pressure-assisting edge qw4, and an angle expansion core qw5. The solid force angle qw1 is connected with the angle expansion core qw5. The end of the corner core qw5 away from the solid angle qw1 is connected to the pressu...

Embodiment 2

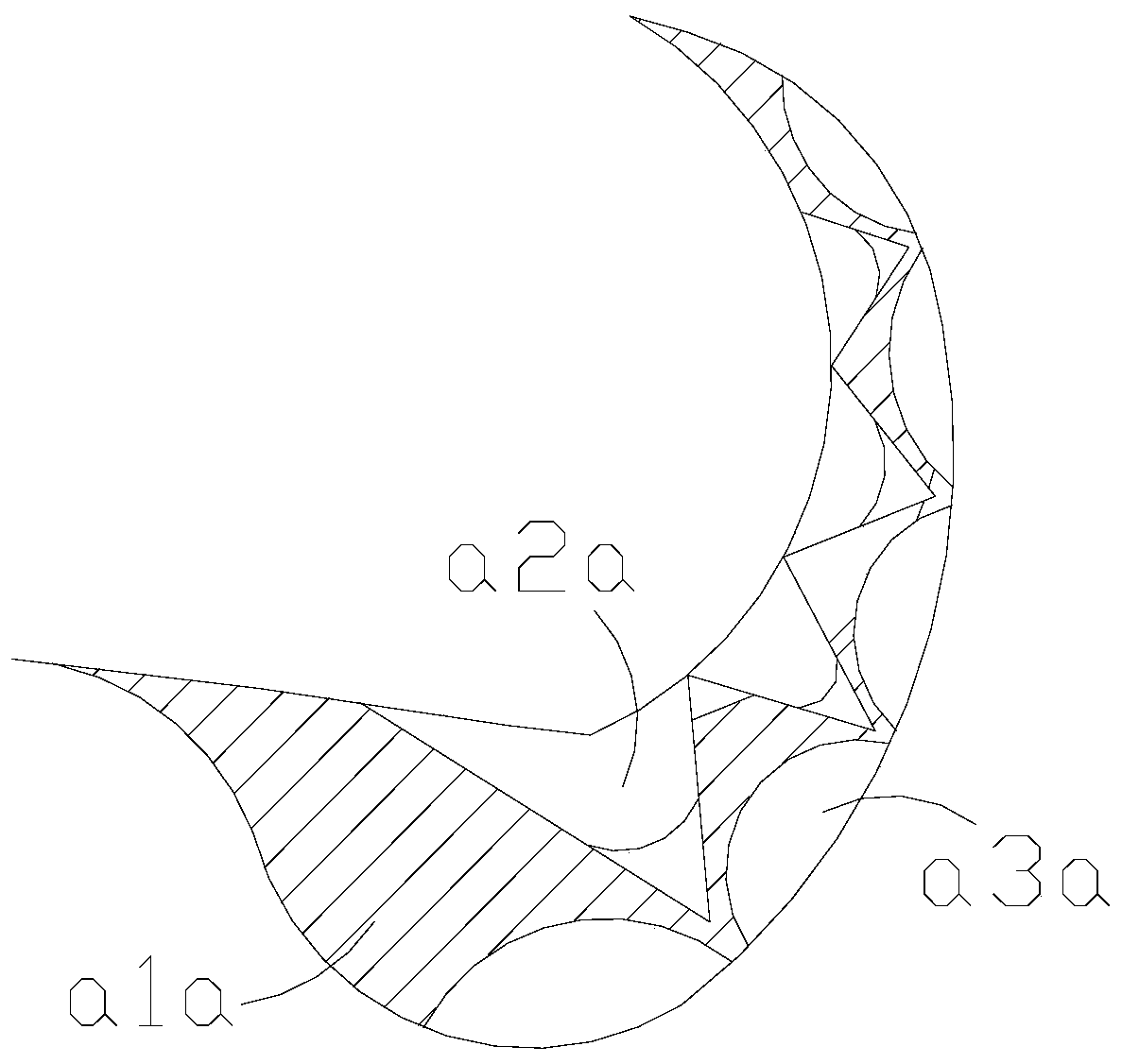

[0040] as attached Figure 6 to attach Figure 8 Shown:

[0041]Wherein, the support filter layer tt03 includes an inlet ee1, an outer limit shell ee2, an extrusion bar ee3, and a grid ee4, the inlet ee1 runs through the inside of the outer limit shell ee2, and the grid ee4 is embedded in the outer limit shell Inside ee2, the intrusion bar ee3 is connected with the outer limit shell ee2, the intrusion bar ee3 is evenly distributed in the horizontal direction, the outer limit shell ee2 is in a circular structure, and the introduction port ee1 limits the movement of foreign objects. The range of the inlet is large, and the strip ee3 is squeezed in to separate the water from the fluff.

[0042] Wherein, the intrusion bar ee3 includes a beam opening xx01, a pocket grid xx02, an outer limit ring xx03, and a one-way angle xx04, and the one-way angle xx04 is connected with the beam opening xx01, and the one-way angle xx04 is embedded in the outer limit Inside the ring xx03, the po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap