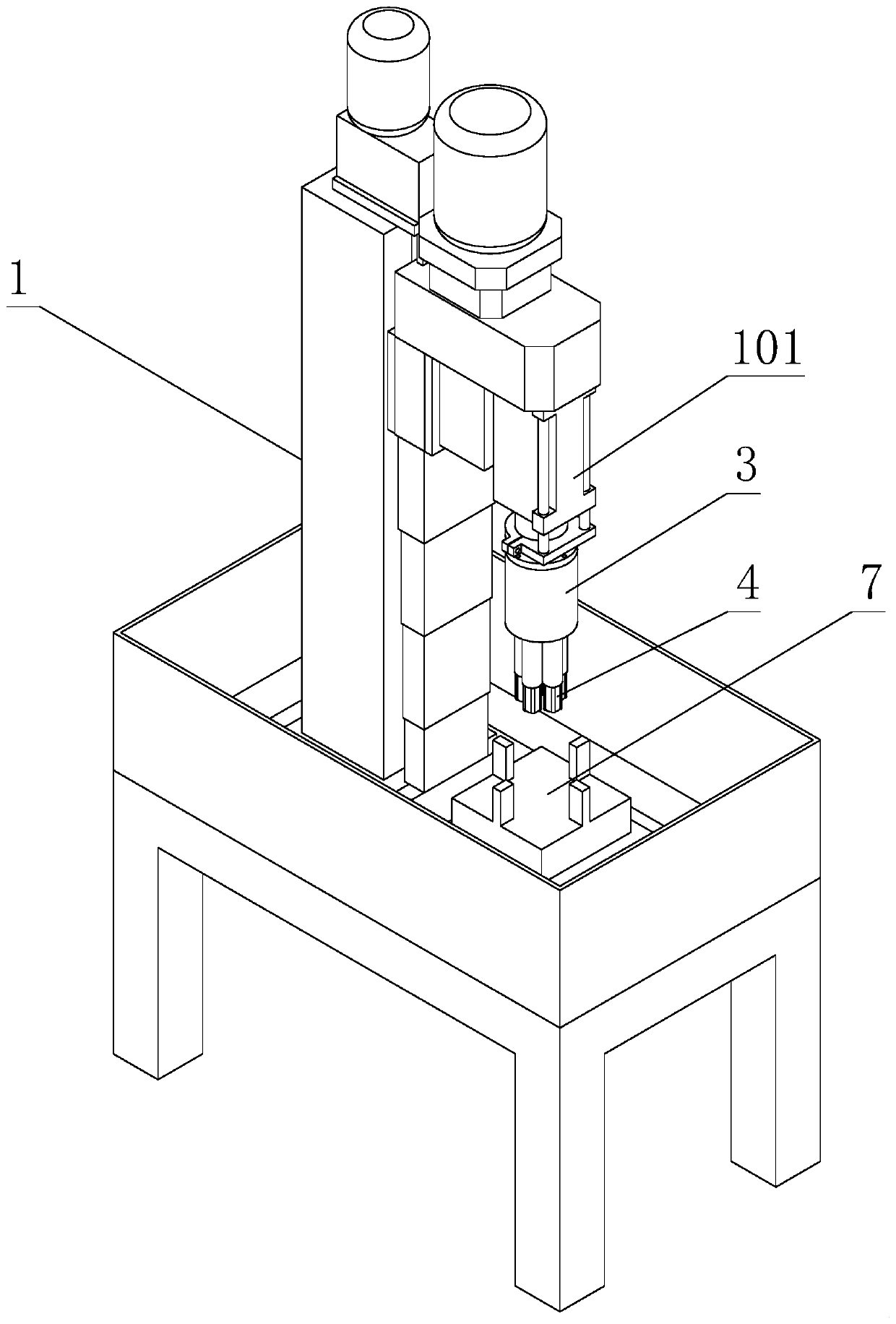

Equipment used for finish machining of cylinder hole in car air conditioner compressor shell

A technology for compressor shells and automotive air conditioners, applied in metal processing equipment, reaming devices, manufacturing tools, etc., can solve the problems of low processing efficiency and achieve high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

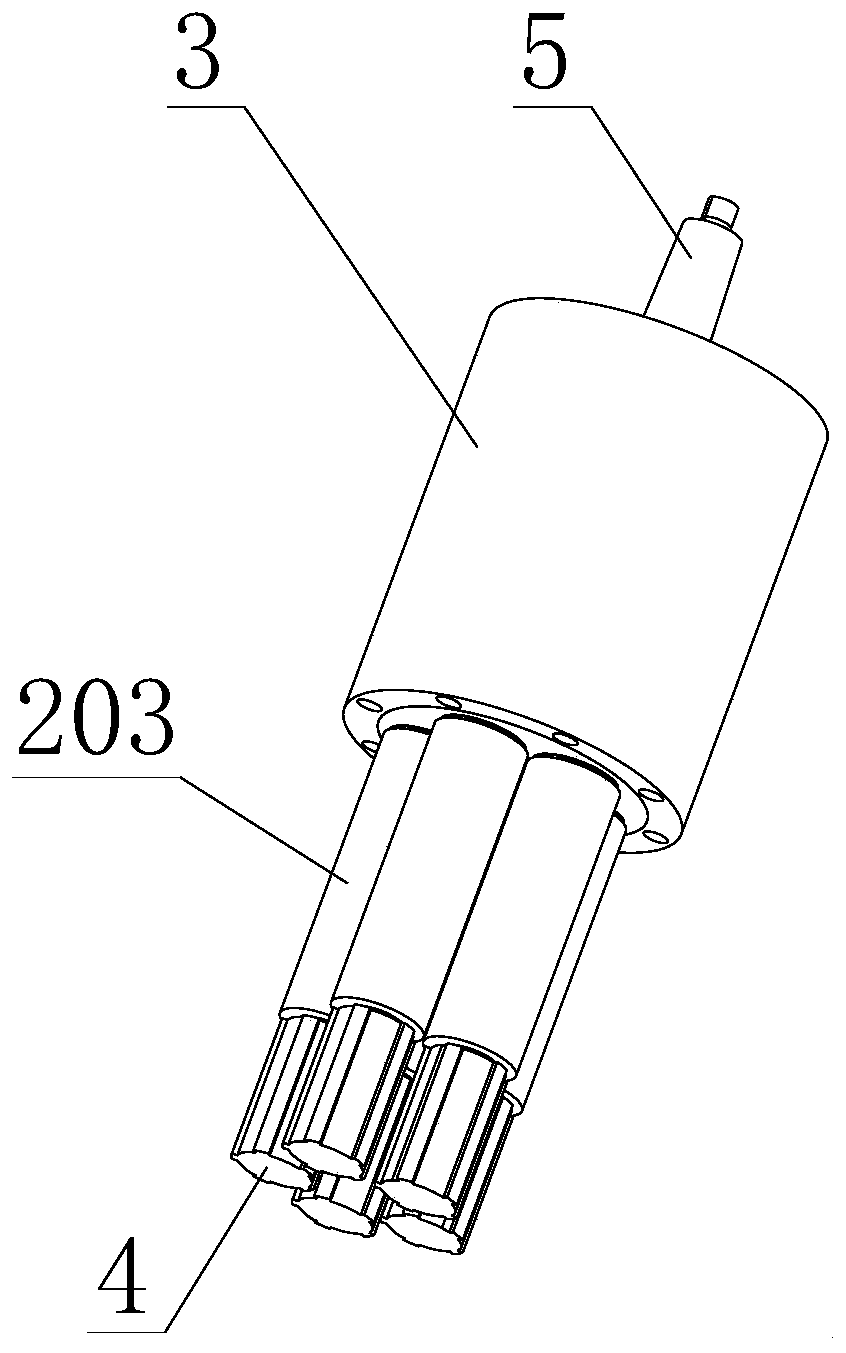

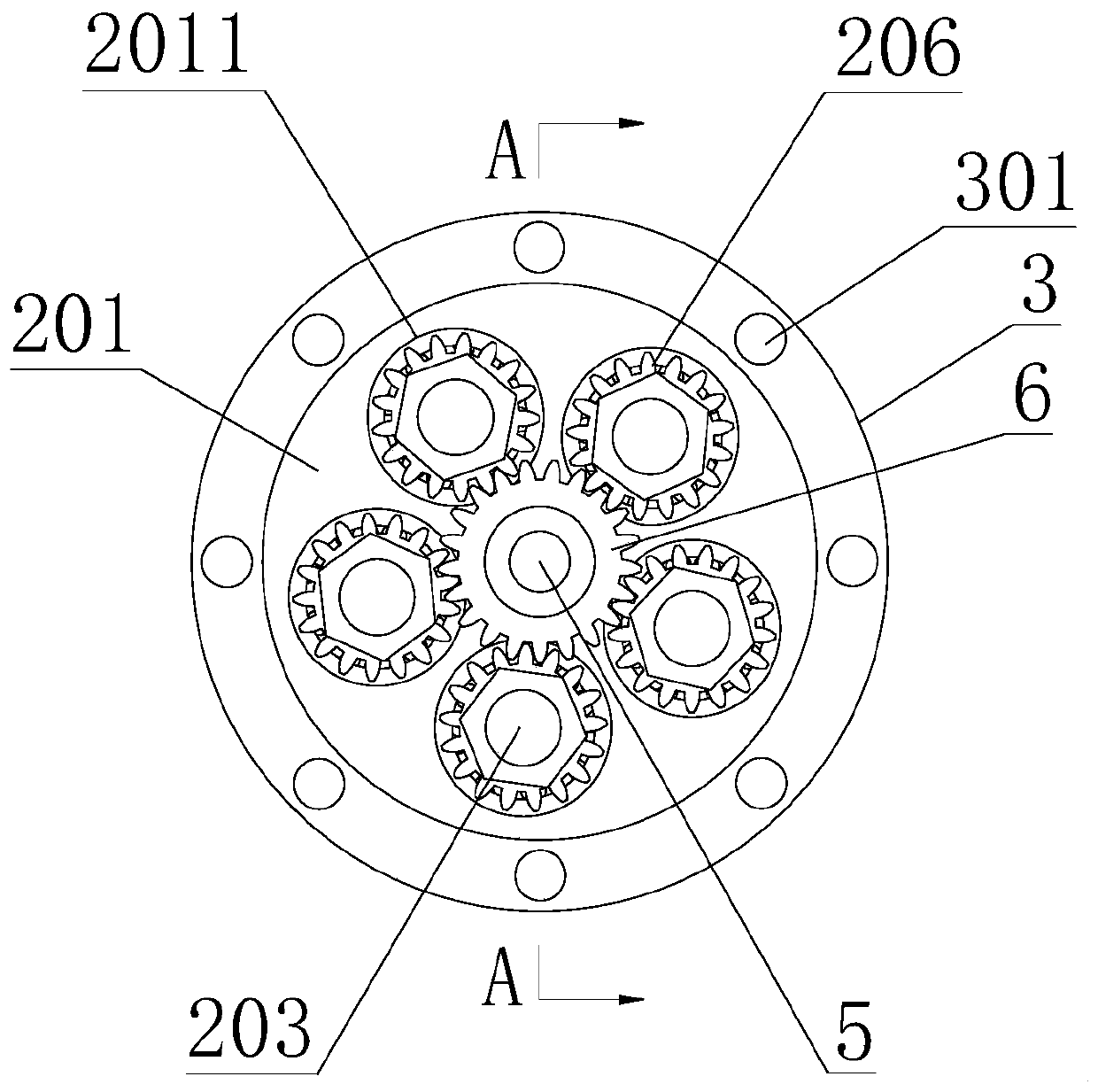

[0025] The A positioning hole 2011 is a stepped hole with the big end on the top, the A bearing 204 is arranged in the big end of the stepped hole, and is against the stepped surface; the B positioning hole 2021 is a stepped hole with the big end on the bottom, so The B bearing 205 is arranged in the big end of the stepped hole and is against the stepped surface. The handle 203 is covered with a positioning sleeve 207, and the two ends of the positioning sleeve 207 are respectively inserted into the small ends of the A positioning hole 2011 and the B positioning hole 2021 to offset the inner ring of the A bearing 204 and the inner ring of the B bearing 205. ; The A bearing 204 and the B bearing 205 are both deep groove ball bearings. The end face of the bearing cooperates with the stepped face to withstand greater axial load and prolong the service life of the bearing. At the same time, it prevents the bearing from being displaced or directly separated from the positioning hol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap