Novel dry process connected energy-consuming beam column joint based on corbel

A beam-column joint and energy-consuming technology, applied in the direction of columns, joists, girders, etc., can solve the problems of affecting the overall mechanical performance of the structure, affecting the construction period, and difficulty in installation, so as to reduce construction professionalism and accuracy, and improve Construction efficiency, reduce the effect of formwork support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of the embodiments of the present invention, not all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

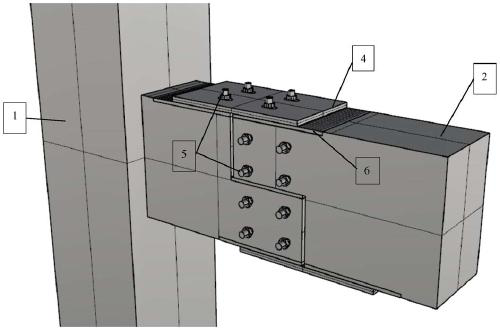

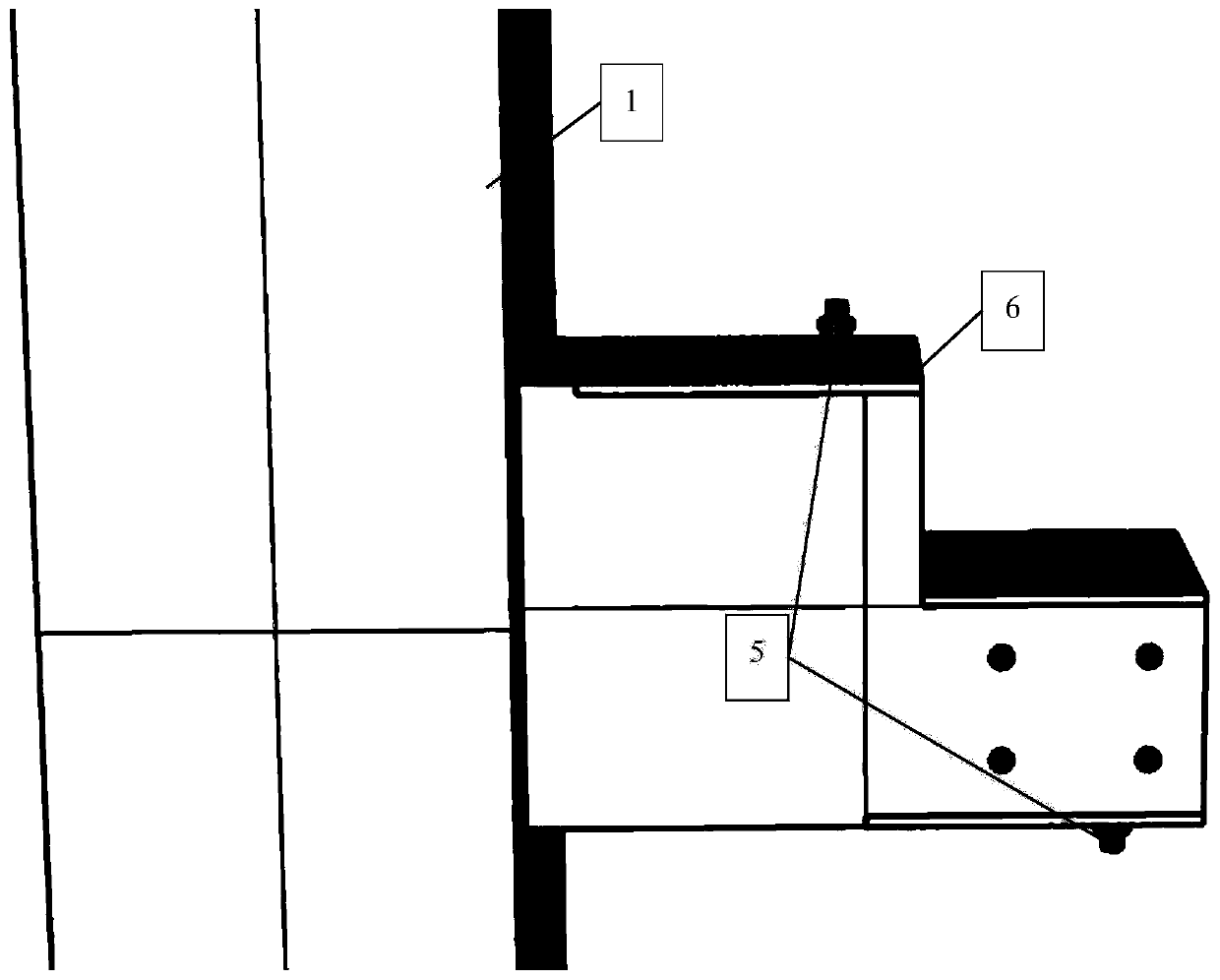

[0038] Such as Figure 1-4 As shown, a new type of dry connection energy-consuming beam-column node in the embodiment of the present application includes high-strength bolts 5 for connection and fastening, and a precast concrete corbel column 1 for bearing vertical loads. Rectangular precast concrete notched beam 2, connecting steel plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap