Preparation method of complex coarse cereal yogurt

A technology for yogurt and miscellaneous grains, which is applied in the direction of milk preservation, milk preparations, and bacteria used in food preparation. It can solve the problems of rough surface of miscellaneous grain yogurt, affect the absorption of yogurt taste, rough taste of yogurt, etc., and achieve solidification stability Excellent, improve the taste and nutritional value, the effect of light yellow color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

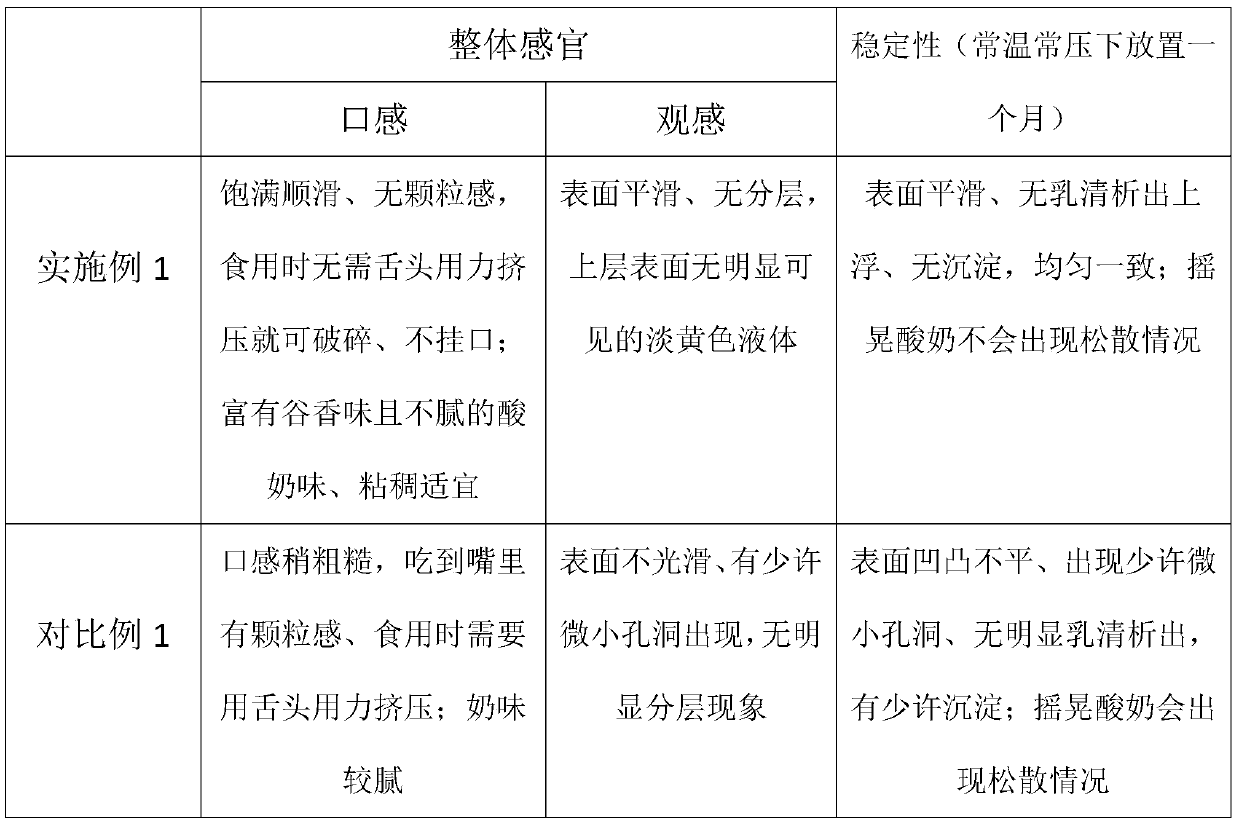

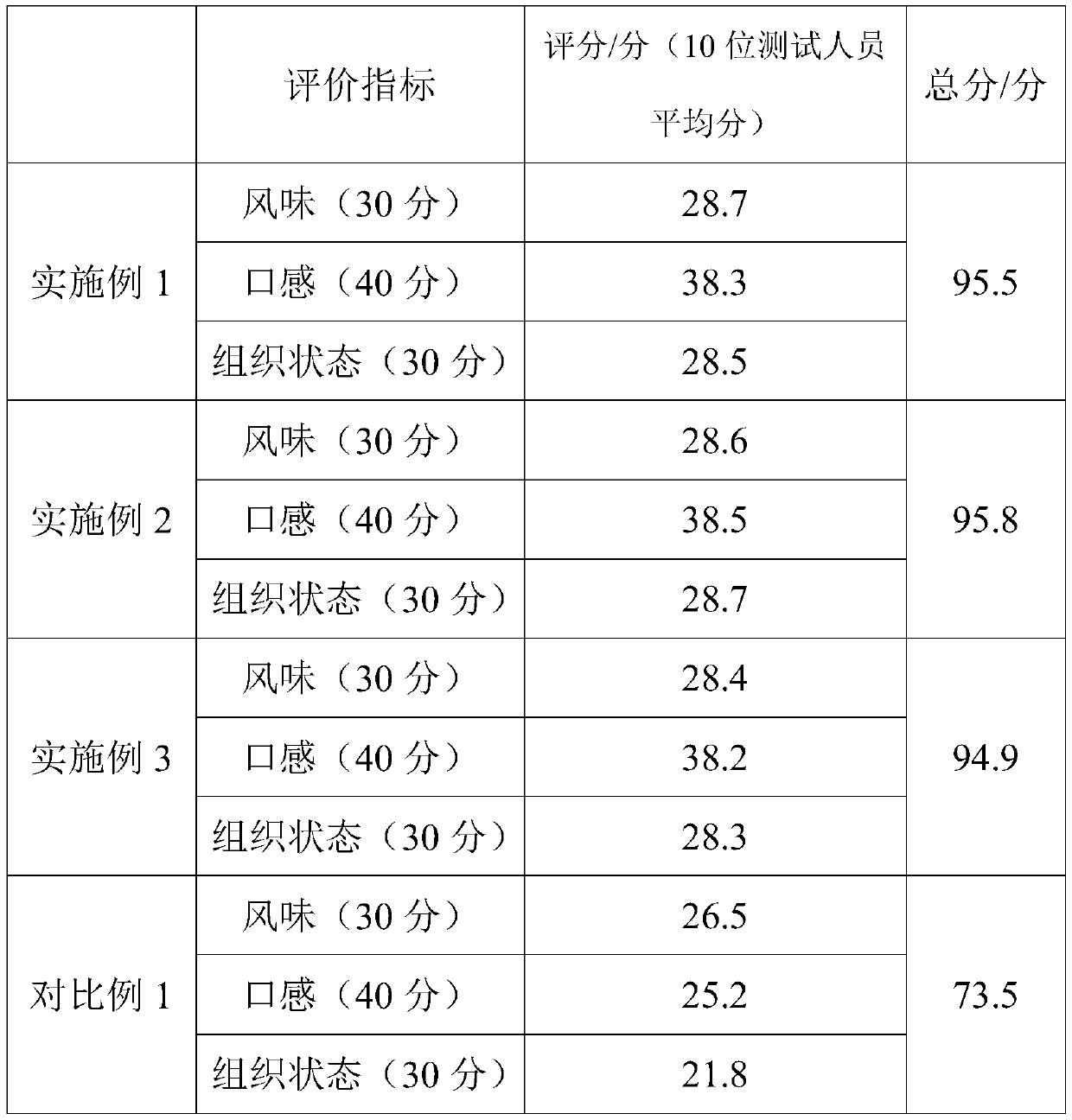

Embodiment 1

[0030] A kind of preparation method of multigrain yoghurt is characterized in that, comprises the following steps:

[0031] a, superfine pulverization: adopt the superfine pulverizer that model is SYFM-8Ⅱ to carry out superfine pulverization to each ripe miscellaneous grain flour (buckwheat flour, millet flour and brown rice flour), pulverize time 5min, obtain powder particle size 10 μm; Then All miscellaneous grain flours are blended in proportion, and the mass ratio of buckwheat flour, millet flour and brown rice flour is 1.7:1:1.1.

[0032] b. Preparation: deploy stabilizer, configure chitosan and gelatin according to the mass ratio of 2.8:0.9; then add skimmed milk powder, sugar, and prepared miscellaneous grain powder to every 100ml of water, then add stabilizer, and heat at 60°C mix evenly;

[0033] Among them, the mass ratio of skimmed milk powder, sugar, and mixed grain powder is 4.3:2.3:1, the mass of skimmed milk powder is 13.5g; the mass of stabilizer is 0.038g.

[0

Embodiment 2

[0051] A kind of preparation method of multigrain yoghurt is characterized in that, comprises the following steps:

[0052] a, superfine pulverization: adopt the superfine pulverizer that model is SYFM-8Ⅱ to carry out superfine pulverization to each mature miscellaneous grain flour (buckwheat flour, millet flour and brown rice flour), pulverize time 6min, obtain powder particle size 17 μm; Then All miscellaneous grain flours are blended in proportion, and the mass ratio of buckwheat flour, millet flour and brown rice flour is 2.1:1.3:1.4.

[0053] b. Preparation: prepare a stabilizer, mix chitosan and gelatin at a mass ratio of 3:1; then add skimmed milk powder, sugar, and mixed grain powder to every 100ml of water, and then add a stabilizer. mix evenly;

[0054] Wherein, the mass ratio of skimmed milk powder, sugar, and blended miscellaneous grain powder is 4.74:2.5:1.2, the mass of skimmed milk powder is 14g; the mass of stabilizer is 0.04g.

[0055] c. Homogenization: Prehea

Embodiment 3

[0062] A kind of preparation method of multigrain yoghurt is characterized in that, comprises the following steps:

[0063] a, superfine pulverization: adopt the superfine pulverizer that model is SYFM-8Ⅱ to carry out superfine pulverization to each mature miscellaneous grain flour (buckwheat flour, millet flour and brown rice flour), pulverize time 8min, obtain powder particle size 25 μ m; Then All miscellaneous grain flours are blended in proportion, and the mass ratio of buckwheat flour, millet flour and brown rice flour is 2.6:1.5:1.6.

[0064] b. Preparation: prepare a stabilizer, mix chitosan and gelatin at a mass ratio of 3.2:1.1; then add skimmed milk powder, sugar, and prepared miscellaneous grain powder to every 100ml of water, and then add a stabilizer. mix evenly;

[0065] Among them, the mass ratio of skimmed milk powder, sugar, and mixed grain powder is 5.1:2.8:1.3, the mass of skimmed milk powder is 14.4g; the mass of stabilizer is 0.042g.

[0066] c. Homogenizat

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap