Micromirror integrated with linear angle sensor

An angle sensor and micromirror technology, which is applied in the direction of instruments, optical components, optics, etc., can solve the problems of inability to apply high frequency and low frequency at the same time, complex angle measurement scheme system, poor process compatibility, etc., and achieve compact structure and low power consumption , The effect of high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

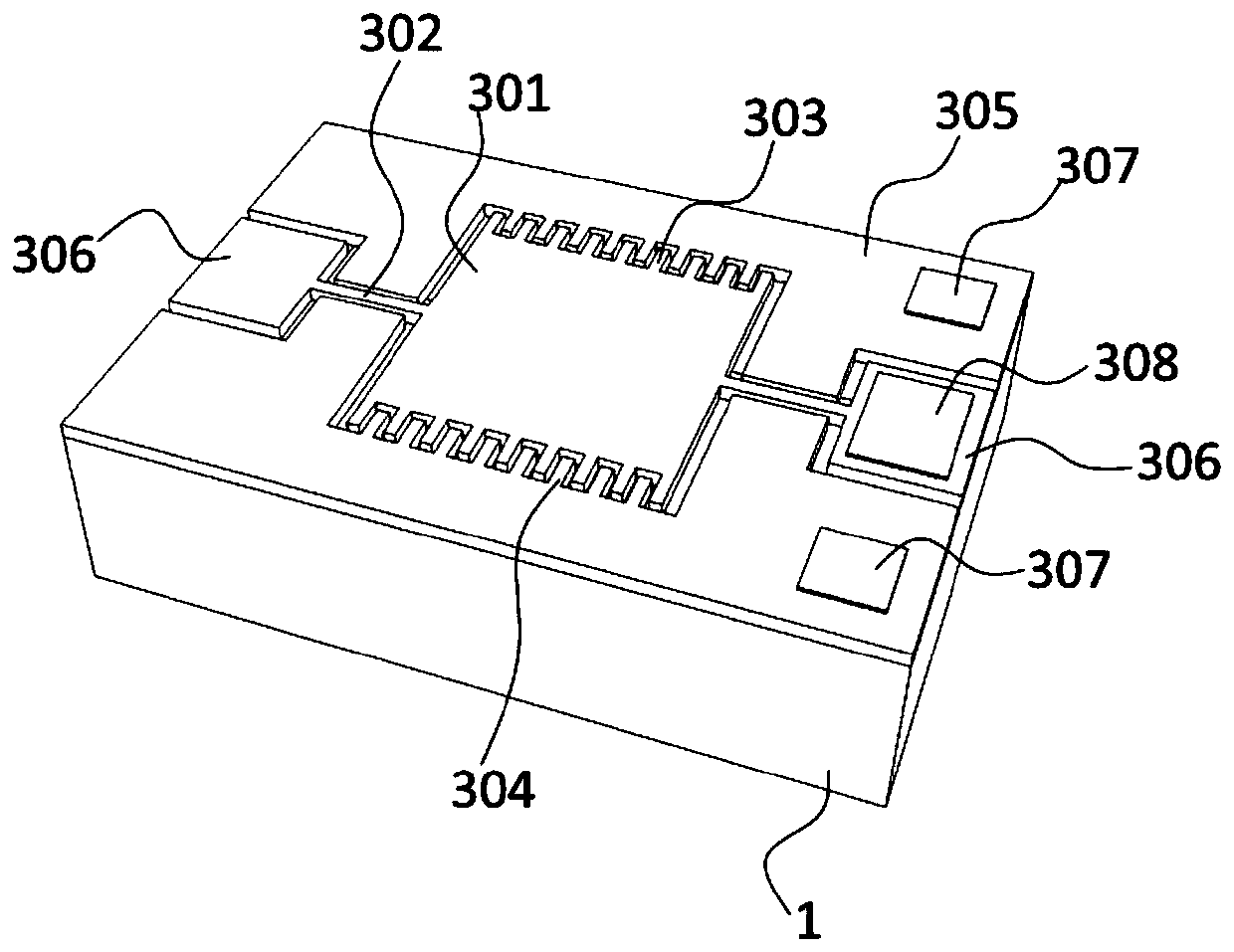

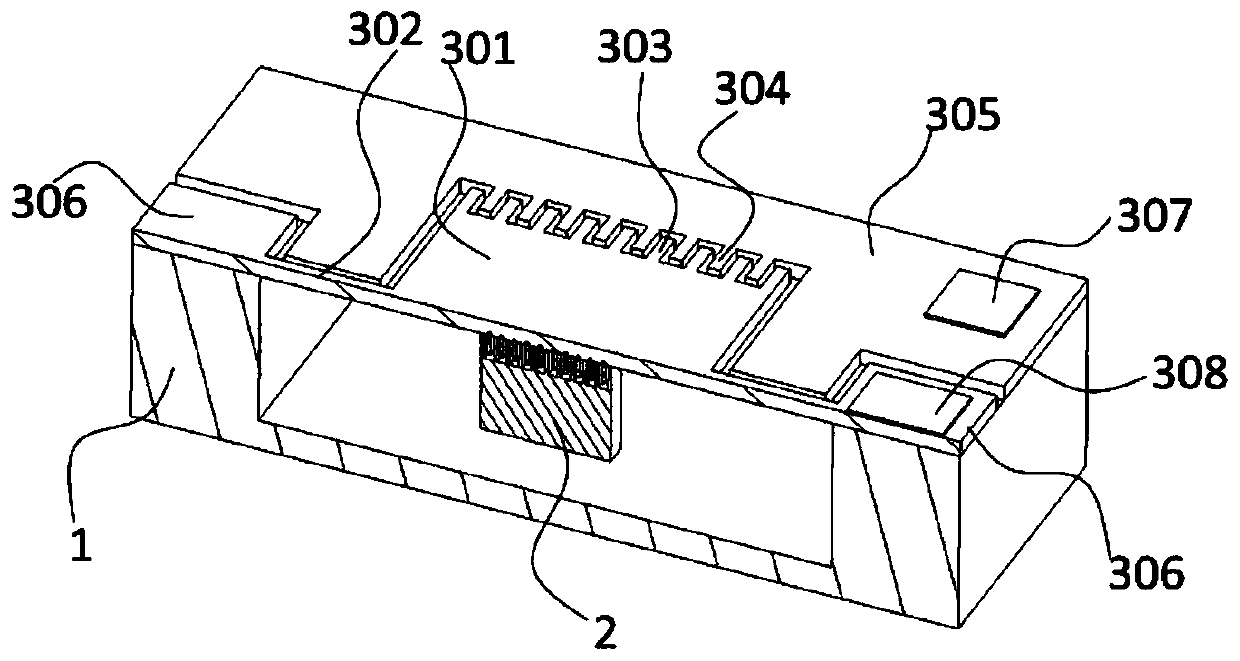

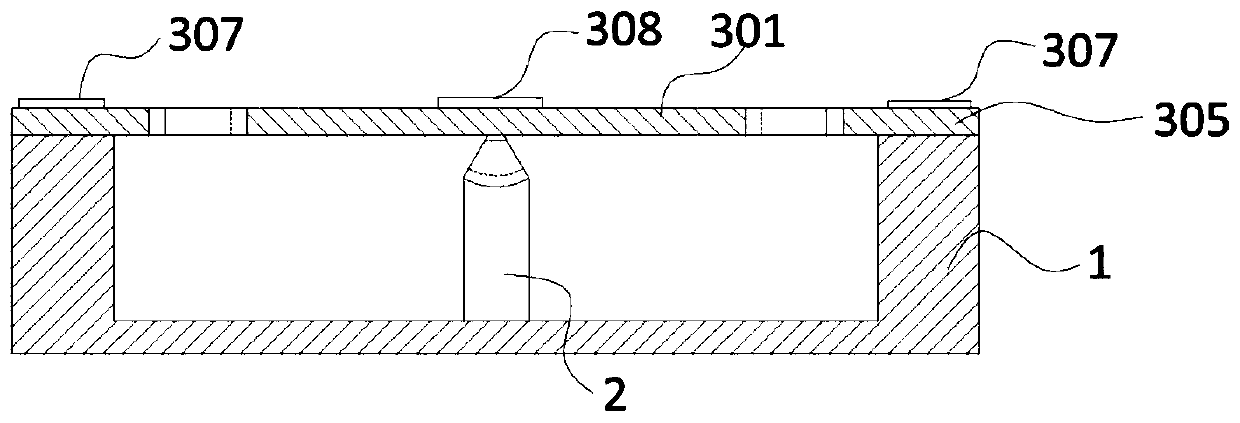

[0036] The micromirror of integrated linear angle sensor described in this embodiment, see Figure 1-7, including a base 1, an angle sensor 2, and a mirror element 3, the base 1 is a groove-like structure formed around the bottom surrounded by a frame, the mirror element 3 is a planar structure, the base 1 and the mirror The elements 3 are connected to form a box body with a hollow structure, and the angle sensor 2 is axially arranged in the hollow structure of the box body. The angle sensor 2 includes a stator 201 and a rotor 202 , and the rotor 202 is arranged on the upper part of the stator 201 . The lower end surface of the stator 201 is fixedly connected to the bottom of the groove-shaped structure of the base 1 , and the upper end surface of the rotor 202 is fixedly connected to the lower surface of the mirror element 3 . Both the stator 201 and the rotor 202 of the angle sensor 2 have fan-shaped array electrodes; the fan-shaped array electrodes of the stator 201 and the f

Embodiment 2

[0039] The micromirror of the integrated linear angle sensor described in this embodiment includes a base 1, an angle sensor 2, and a reflector element 3. The base 1 is a groove-like structure formed around the bottom surrounded by a frame, and the reflector element 3 It is a planar structure, the base 1 is connected with the reflector element 3 to form a box with a hollow structure, and an angle sensor 2 is axially arranged in the hollow structure of the box.

Embodiment 3

[0041] The micromirror of the integrated linear angle sensor described in this embodiment includes a base 1, an angle sensor 2, and a reflector element 3. The base 1 is a groove-like structure formed around the bottom surrounded by a frame, and the reflector element 3 It is a planar structure, the base 1 is connected with the reflector element 3 to form a box with a hollow structure, and an angle sensor 2 is axially arranged in the hollow structure of the box. The angle sensor 2 includes a stator 201 and a rotor 202 , and the rotor 202 is arranged on the upper part of the stator 201 . The lower end surface of the stator 201 is fixedly connected to the bottom of the groove-shaped structure of the base 1 , and the upper end surface of the rotor 202 is fixedly connected to the lower surface of the mirror element 3 . Both the stator 201 and the rotor 202 of the angle sensor 2 have fan-shaped array electrodes; the fan-shaped array electrodes of the stator 201 and the fan-shaped array

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap