Preparation method of high-performance calcium manganate energy storage electrode material

A high-performance calcium manganate and energy storage electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., to achieve the effects of simple preparation method, increased conductivity, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1), the preparation of high performance calcium manganate energy storage electrode material comprises the following steps:

[0024] S1), 0.1mol L -1 Calcium chloride, 0.2mol L -1 Manganese salt and 0.75mol L -1 Potassium hydroxide, being dissolved in the mixed solvent that is the ratio of ethanol and water is 5:3, after stirring until completely dissolving, obtain precursor solution, wherein, manganese salt is the mixture of manganese chloride and potassium permanganate, wherein, The manganese salt is manganese chloride and potassium permanganate in a mass ratio of 8:2;

[0025] S2), pour the precursor solution into the reaction kettle, react in an oven at 150°C for 12 hours, and then centrifuge, wash, and dry to synthesize CaMn 2 o 4 Powder, denoted as CaMn 2 o 4 -blank;

[0026] S3), the CaMn synthesized in step S2) 2 o 4 powder CaMn 2 o 4 -blank is placed in a tube furnace, under the atmosphere of ammonia gas, and at a temperature of 700°C, anneal for 90 minu

Embodiment 2-5

[0035] Based on the scheme of Example 1, the properties of calcium manganate after annealing are affected by adjusting different annealing conditions, and the relationship is shown in Table 1.

[0036] Table 1: Annealing regulation of calcium manganate

[0037]

[0038]

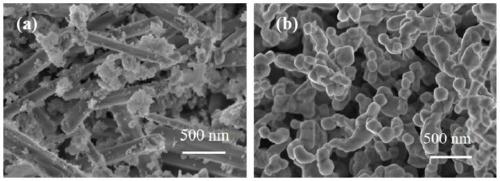

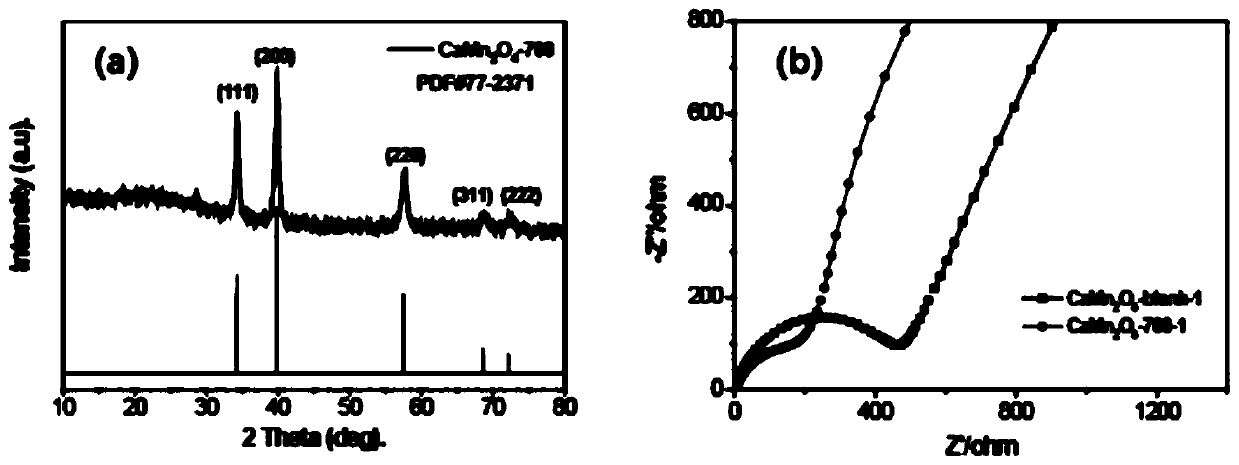

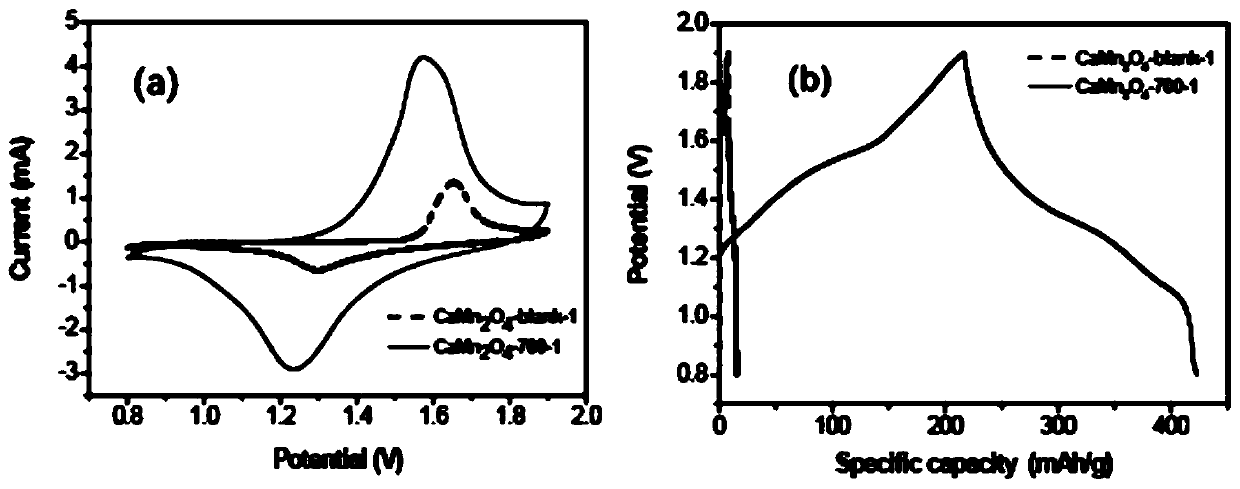

[0039] Wherein, embodiment 1, 2 and 3 illustrate that the annealing temperature has a great influence on the performance of manganic acid, and embodiment 1, 4 and 5 illustrate that the time factor also affects the performance of calcium manganate to a certain extent. The performance of calcium manganate after annealing in the described embodiments 2-5 is not as good as the case of embodiment 1. As can be seen from the above examples, under the atmosphere of ammonia gas, calcium manganate CaMn 2 o 4 After the annealing reaction, the morphology of the material changes, while the conductivity increases and the number of active sites increases, thereby effectively improving the specific capacity and rate per

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap