Installation structure of cleaning rag

A technology for installing structures and rags, which is applied to cleaning equipment, cleaning machinery, and carpet cleaning, etc., can solve the problems of reduced water seepage performance, reduced water seepage performance of rags, and high mold costs, and achieves convenient installation and use, good fixing effect, and low processing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

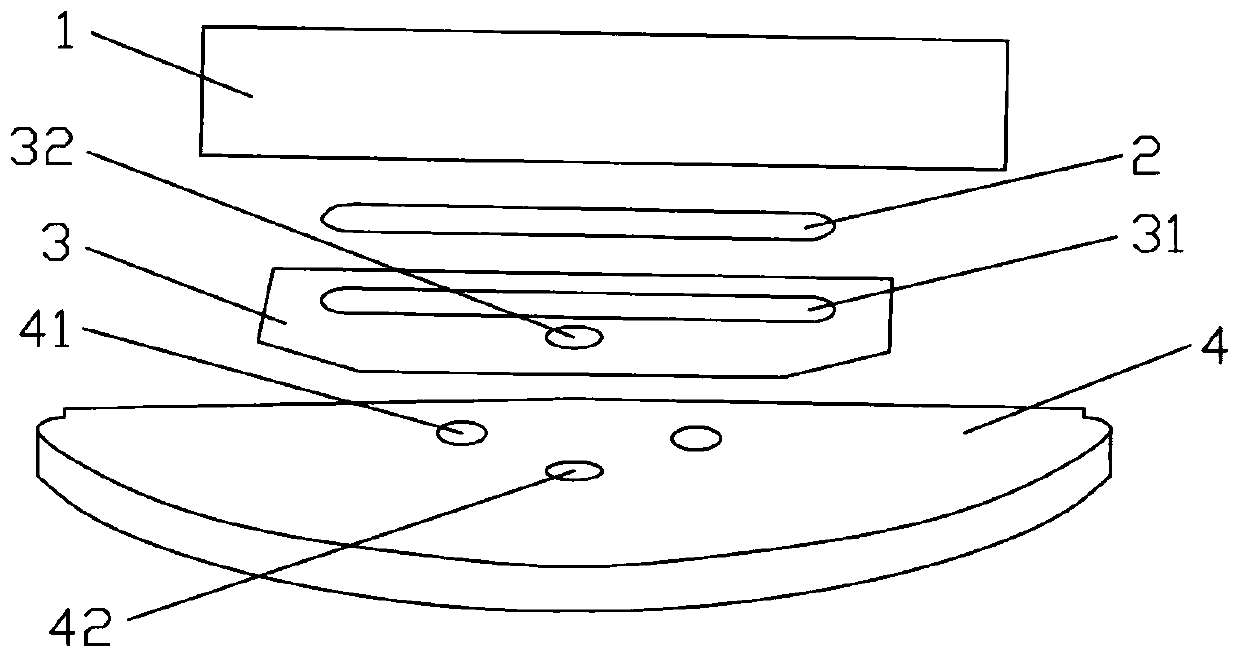

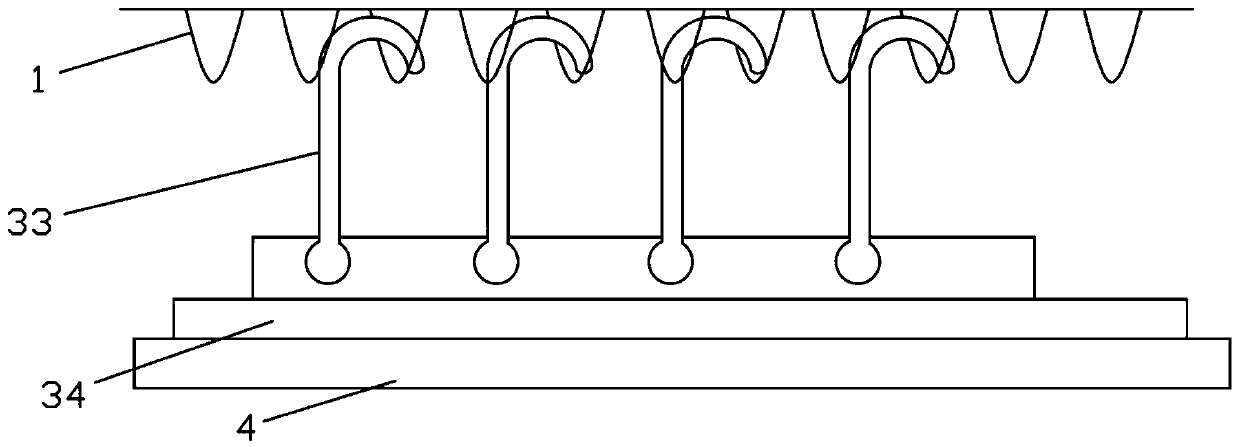

[0018] Such as figure 1 and figure 2 As shown, the installation structure of a cleaning rag according to the present invention includes Velcro 3, and the Velcro 3 is provided with a capsule-shaped hole 31 corresponding to the water seepage hole 41 of the seepage water tank 4 and a water tank corresponding to the seepage water tank 4. The air hole 42 corresponds to the circular hole 32, the capsule-shaped hole 31 and the water seepage hole 41 of the seepage water tank 4 are provided with a water seepage cloth 2, and the Velcro 3 and the water seepage cloth 2 are covered with a disposable rag 1. The upper surface of the paste 3 is provided with a Velcro hook 33 that can be used to paste the disposable rag 1, and the lower surface of the Velcro 3 is provided with a low-viscosity self-adhesive 34 that can be used for pasting and fixing on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap