Vehicle body, bonding and coating structure for automatic driving rain and snow prevention and heat preservation

A self-driving, bonded structure technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., to achieve the effects of less dosage, avoiding foaming and cracking, and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

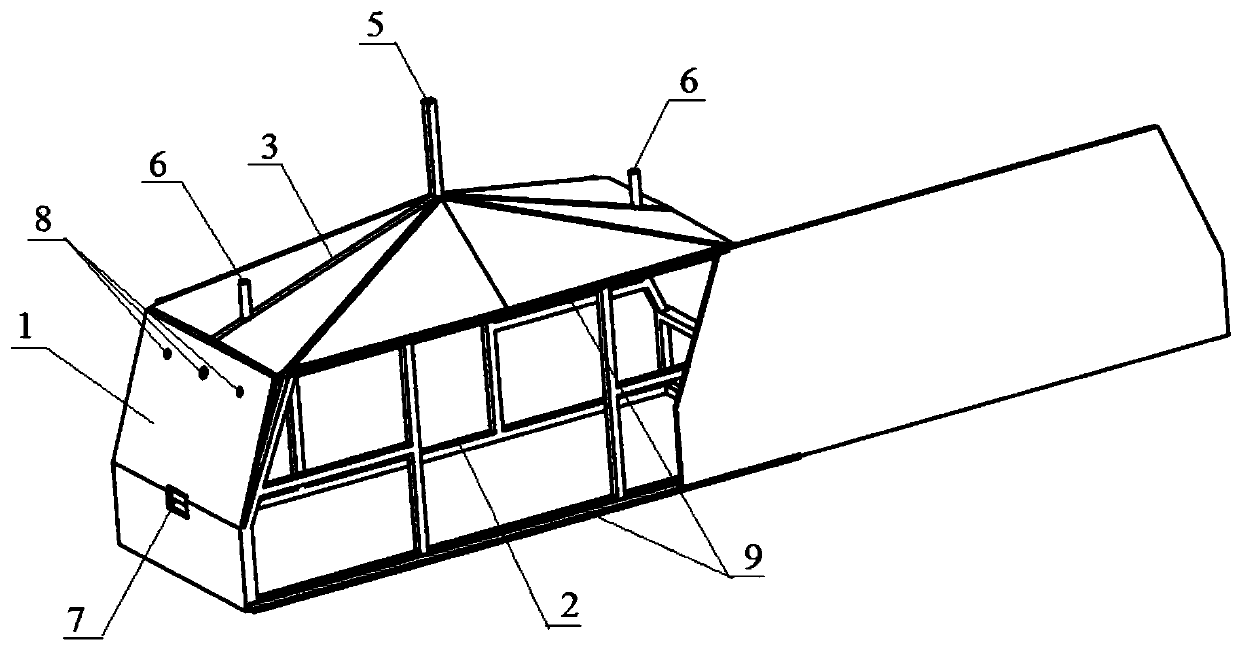

[0024] See figure 1 with figure 2 Shown:

[0025] The car body, bonding and coating structure for automatic driving rain and snow protection and heat preservation provided by the present invention includes a shell 1 and a frame 2, wherein the shell 1 is covered on the frame 2, and the top surface of the shell 1 is connected to The side surface and the front and rear ends are connected by a bonding structure 3, and the inner and outer surfaces of the housing 1 are coated with a coating structure 4.

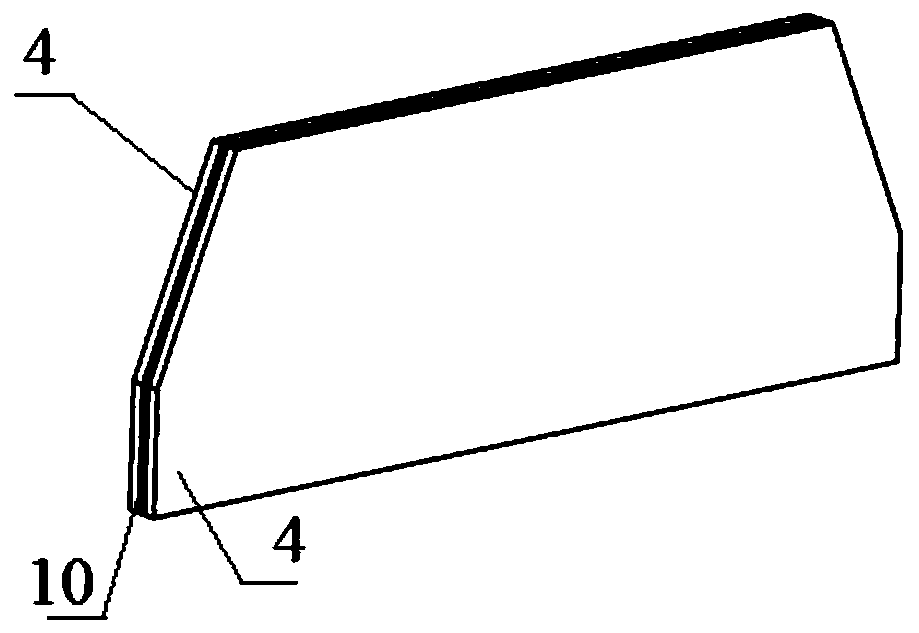

[0026] The shell 1 is made of glass steel plate 10. The top surface of the shell 1 is a lidar hole shell, and the top surface of the shell 1 is an umbrella structure. The angle between the top surface of the shell 1 and the horizontal plane is 15°. The top surface of the shell 1 It is composed of eight glass steel sheets 10 that intersect each other. Adjacent glass steel sheets 10 forming the top surface of the housing 1 are bonded by a bonding structure 3, and a lidar support frame 5 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap