Lithium battery core with conductive electrode lugs

A lithium battery and tab technology, applied in the field of lithium battery cells, can solve problems such as non-conduction of metal layers, and achieve the effects of avoiding virtual welding, reducing production costs, and increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

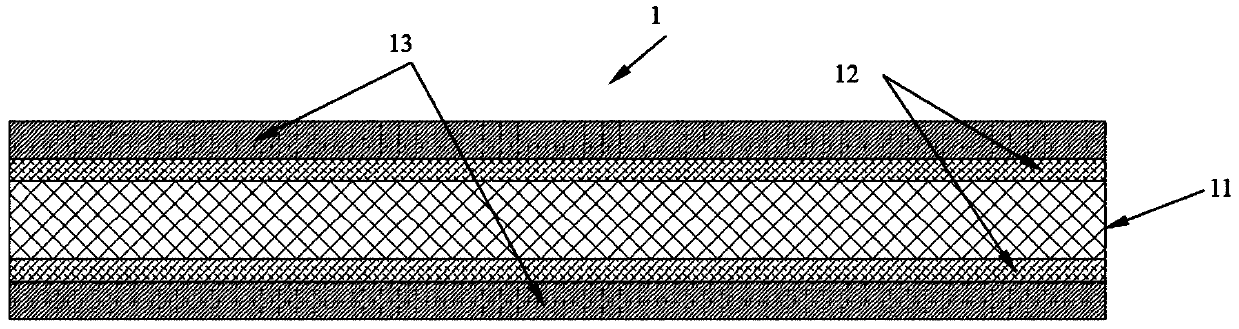

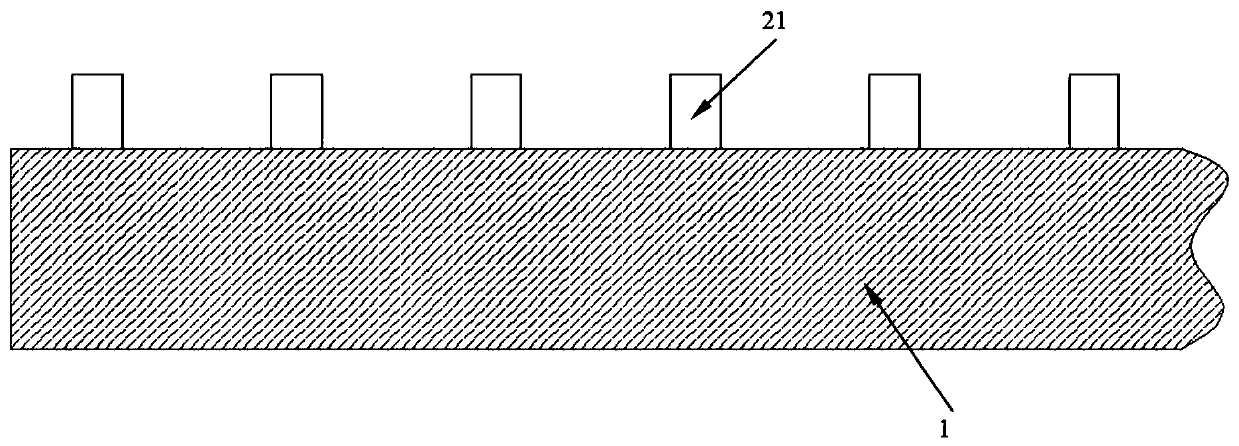

[0047] see Figure 1-7 , Figure 10 , Figure 24 , in an embodiment of the present invention, a lithium battery cell with tabs turned on includes a pole piece 1, the pole piece 1 includes a positive pole piece and a negative pole piece, and the positive pole piece and the negative pole piece are wound to form a battery cell 4, A diaphragm is arranged between the positive pole piece and the negative pole piece, and the lug bundles 23 on the positive pole piece and the negative pole piece are located at both ends of the battery core 4 respectively. The pole piece metal layer 12, the side of the pole piece metal layer 12 away from the pole piece insulating layer 11 is provided with an active material layer 13; the side of the pole piece 1 is provided with a tab part 2, and the tab part 2 includes at least one pole piece 1 fixedly connected tab bundle 23, the tab bundle 23 includes at least one tab piece 21, the tab piece 21 includes a tab insulating layer 22 and tab metal layers 2

Embodiment 2

[0050] see Figure 8-10 , Figure 24 , In this embodiment, three pole lug beams 23 are provided on one side of the pole piece 1, and the rest of the structures are the same as those in Embodiment 1.

Embodiment 3

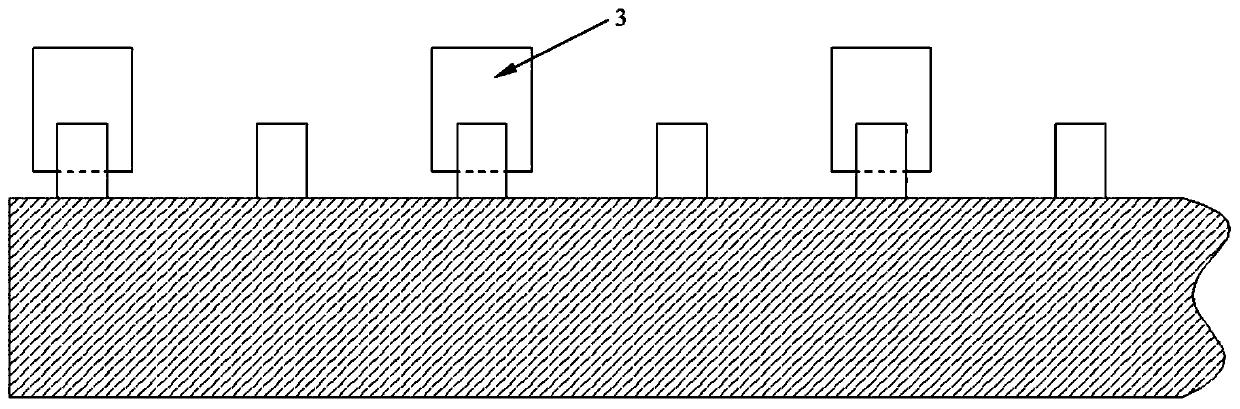

[0052] see Figure 11-15 , Figure 22-24 , in this embodiment, the projection of any tab piece 21 in the tab bundle 23 on the plane where the cell 4 is located does not overlap with the projections of all other tab pieces 21, and the tab bundle 23 is wrapped with conductive foil material 3, the tab bundle 23 includes a plurality of concentrically arranged tab pieces 21, and the tab piece 21 is provided with an adjacently arranged Nth tab piece 25 and an N+1th tab piece 26, and the Nth tab piece The end of the piece 25 away from the pole piece 1 is wrapped inside the N+1th tab piece 26, where N≥1, that is, in this embodiment, the tab piece 21 is a hollow structure in the middle, and the tab piece 21 is a rectangular structure, The hollowed out part has a rectangular structure, and the tab piece 21 at the center is not hollowed out, so after the pole piece 1 is wound, the hollowed out tab pieces 21 are nested in sequence to form a rectangular tab bundle 23, and then The tab bundl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap