Cadmium sulfide quantum dot and preparation method thereof

A technology of quantum dots and cadmium sulfide, which is applied in the field of nanomaterial preparation, can solve the problems of complex steps, pollution, and high cost, and achieve the effect of improving dispersion and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 200g of potatoes, peel and cut into pieces, and put them in a clean beaker for later use. Add 500ml of deionized water into a beaker with potatoes cut into pieces, heat to boil and start timing. After boiling for 30 minutes, cool to room temperature, filter through eight layers of gauze and add deionized water to the filtrate to 1L to obtain potato extract liquid.

[0026] Add 5.6g thioacetamide (TAA) and 275mg cadmium sulfate to the potato extract successively, after stirring evenly, distribute in 12 150ml Erlenmeyer flasks, put into electronic steam pressure sterilizer after sealing, at 121 ℃, 102kPa conditions for 20min, cooled to room temperature, to obtain uniformly dispersed cadmium sulfide quantum dots.

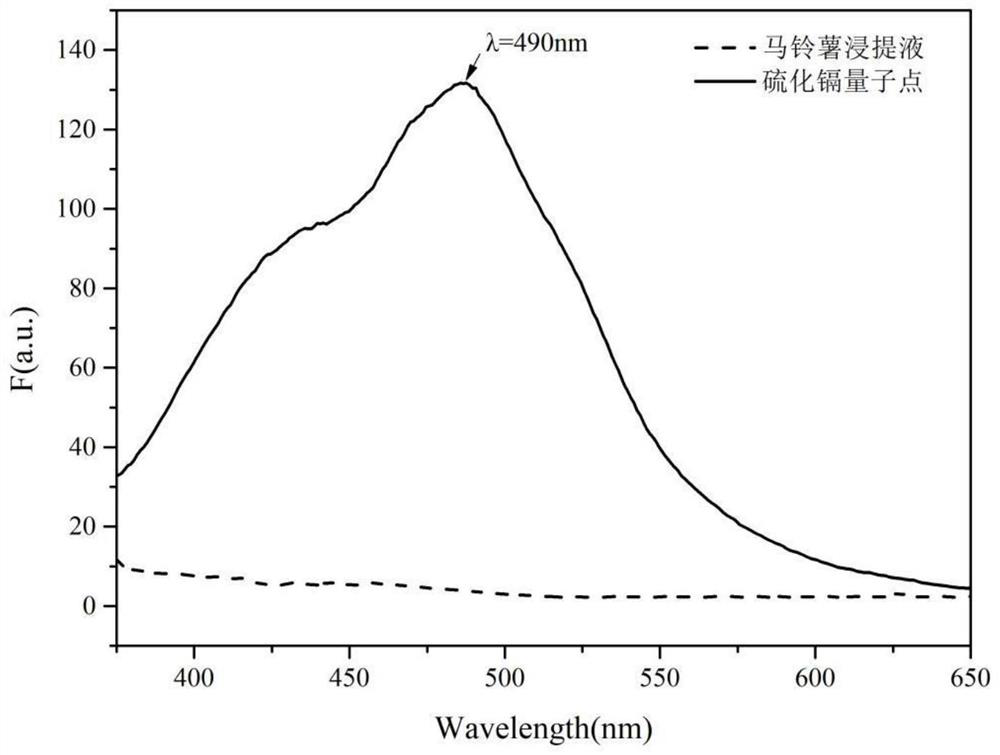

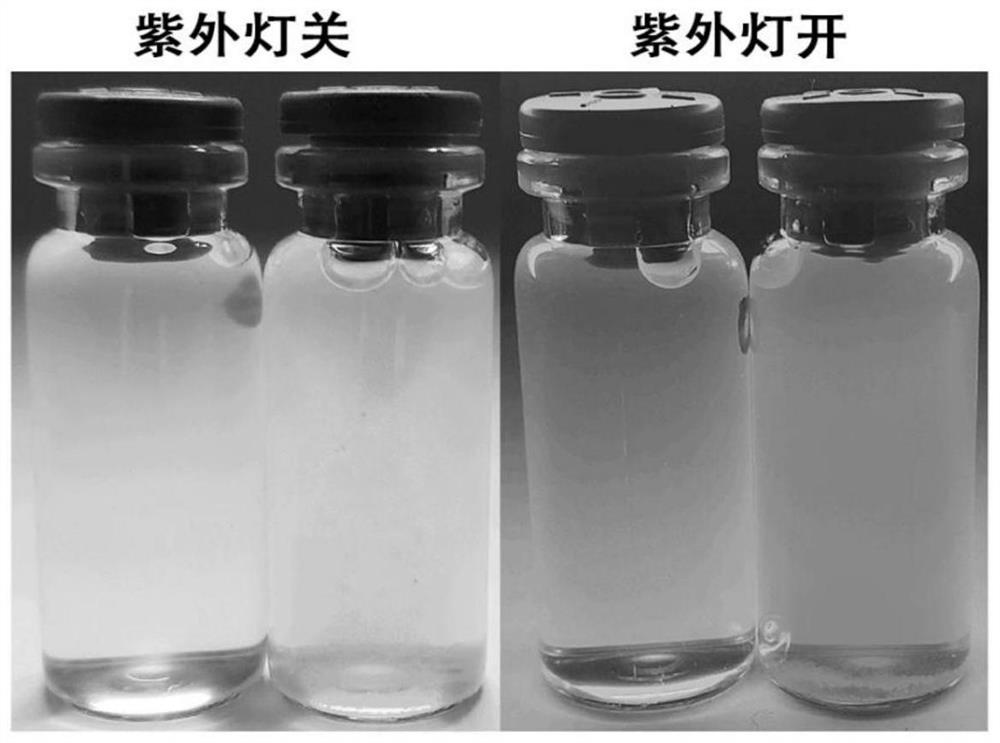

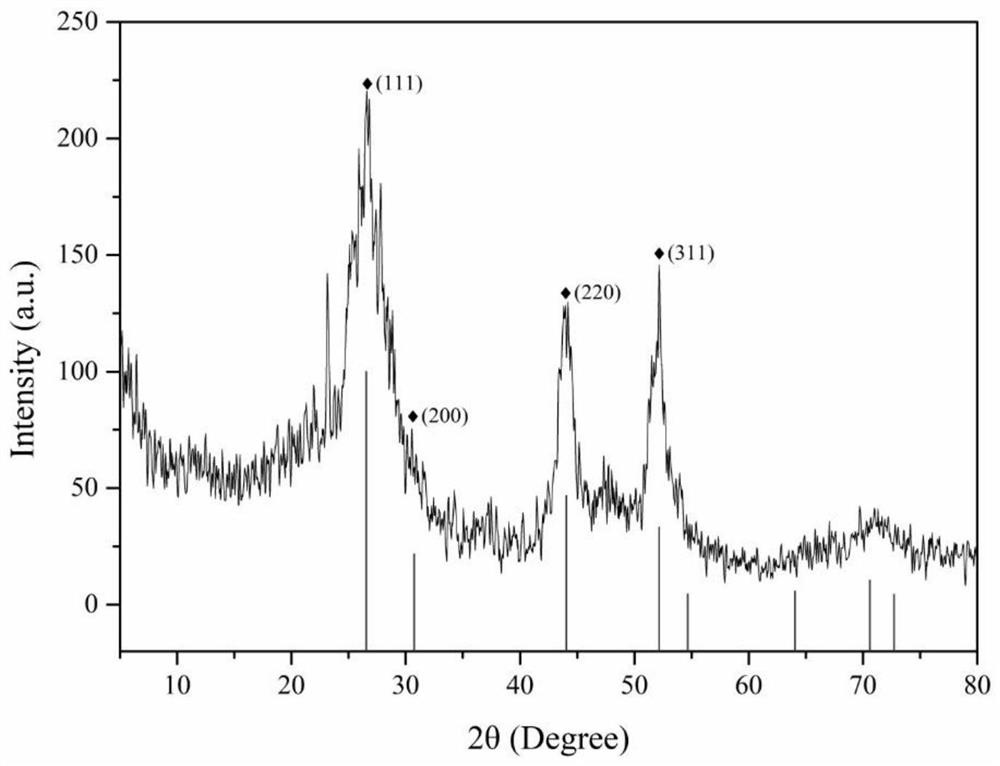

[0027] The cadmium sulfide quantum dot solution prepared in embodiment 1 and potato extract are carried out to fluorescence emission spectrum detection (as figure 1 ), and simultaneously measure the potato extract and the cadmium sulfide quantum dot solutio

Embodiment 2

[0029] Weigh 60g of sweet potato, peel and cut into pieces, and put it in a clean beaker for later use. Add 500ml of deionized water into the beaker with cut sweet potatoes, heat it to boiling and start timing. After boiling for 20 minutes, cool to room temperature, filter through eight layers of gauze, and add deionized water to the filtrate to 1L to obtain sweet potato extract liquid.

[0030] Add 1.2g of thioacetamide (TAA) and 125mg of cadmium sulfate to sweet potato extract successively, after stirring evenly, divide into 13 150ml Erlenmeyer flasks, put into electronic steam pressure sterilizing pot after sealing, at 121 ℃, 102kPa conditions for 20min, cooled to room temperature, to obtain uniformly dispersed cadmium sulfide quantum dots.

Embodiment 3

[0032] Weigh 60g of taro and 50g of sweet potato, peel and cut into pieces, and put them in a clean beaker for later use. Add 500ml of deionized water to the beaker with taro and sweet potatoes cut into pieces, heat to boil and start timing. After boiling for 22 minutes, cool to room temperature, filter through eight layers of gauze, and add deionized water to the filtrate to 1L to obtain taro , sweet potato mixed extract.

[0033] Add 4.3g thioacetamide (TAA) and 220mg cadmium sulfate to the mixed extract successively, after stirring evenly, distribute in 20 150ml Erlenmeyer flasks, put into electronic steam pressure sterilizer after sealing, at 121 ℃, 102kPa, reacted for 23min, cooled to room temperature, and uniformly dispersed cadmium sulfide quantum dots were obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap