Machining positioning device

A positioning device and machining technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of reducing machining accuracy, affecting grinding processing, workpiece offset, etc., and achieving the effect of not easy sliding offset, ensuring grinding processing, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

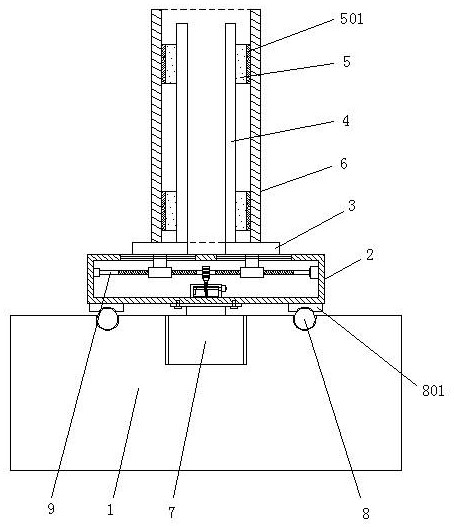

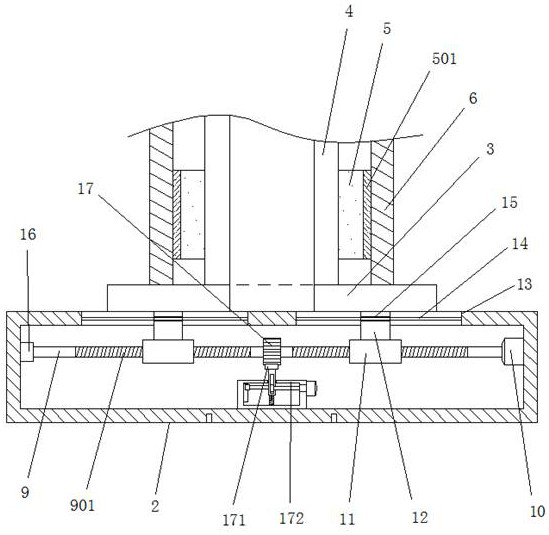

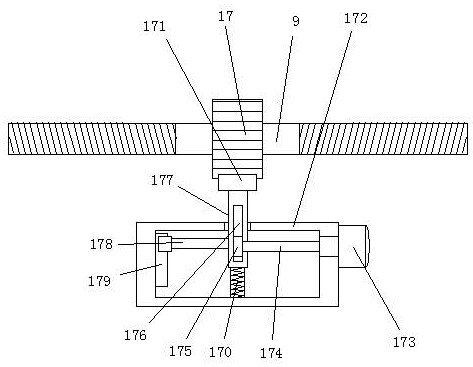

[0027]Example

[0028]referenceFigure 1-6In this embodiment, a mechanical processing positioning device is proposed, which includes a support base 1 and a rotating platform 2 rotatably mounted on the support base 1. The rotating platform 2 is a hollow structure, and both sides of the top of the rotating platform 2 are fixed and sliding A sliding plate 3 is provided. The inner sides of the upper surfaces of the two sliding plates 3 are fixedly connected with a vertical positioning frame 4, and the two positioning frames 4 are fixedly provided with a positioning block 5 on the side away from each other. There is the same pipe fitting 6, and the pipe fitting 6 is sleeved on the outside of the two positioning frames 4 and positioned against the inner wall of the pipe fitting 6 by the positioning block 5, the bottoms of the two sliding plates 3 are fixedly connected with the sliding block 12, and the rotating table 2 The top inner wall of the cavity is symmetrically provided with transverse th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap