Mold and manufacturing process thereof

A mold and process technology, applied in the field of mold and its manufacturing process, can solve problems that are not conducive to improving product timeliness and cost competitiveness, cost reduction, and lengthened development cycle, so as to improve mold forming efficiency, facilitate cooling and solidification, and prevent The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

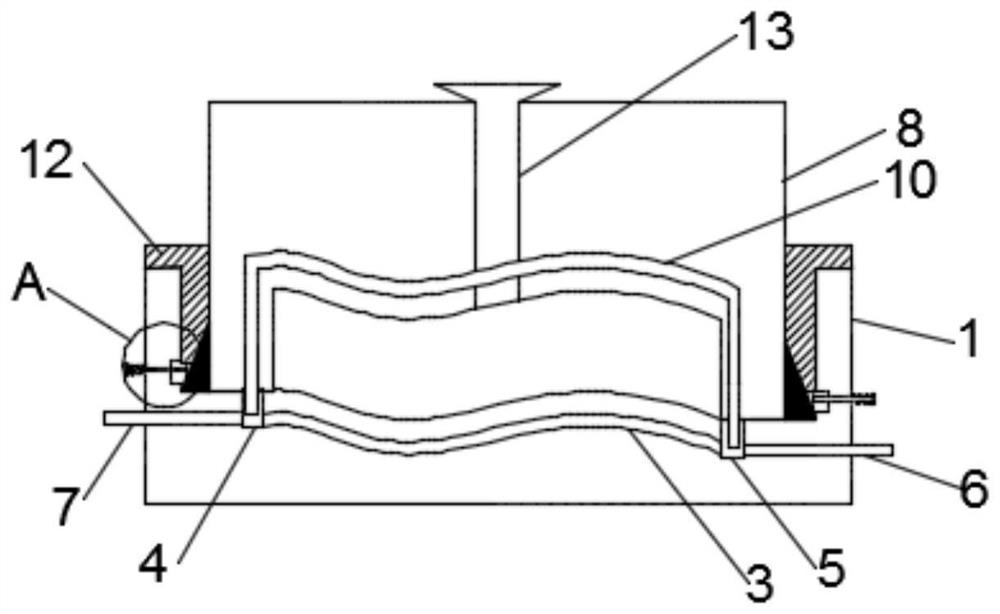

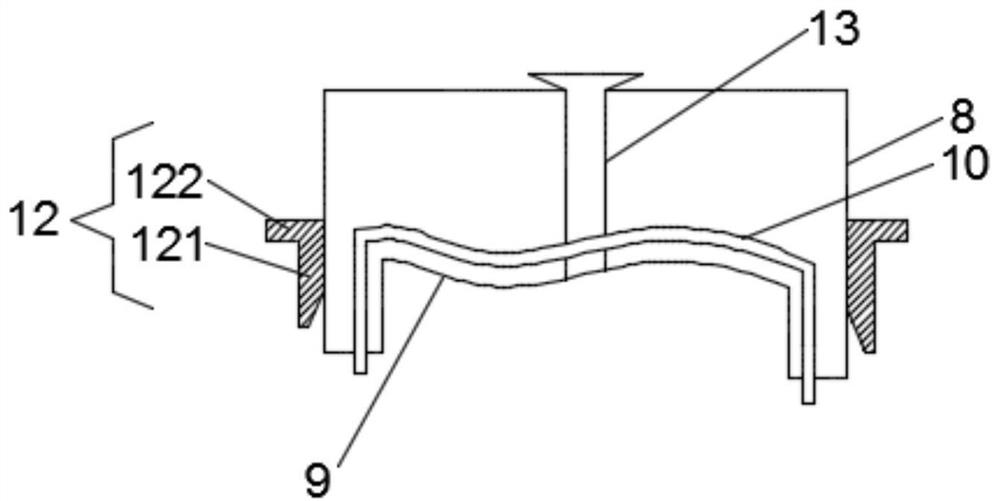

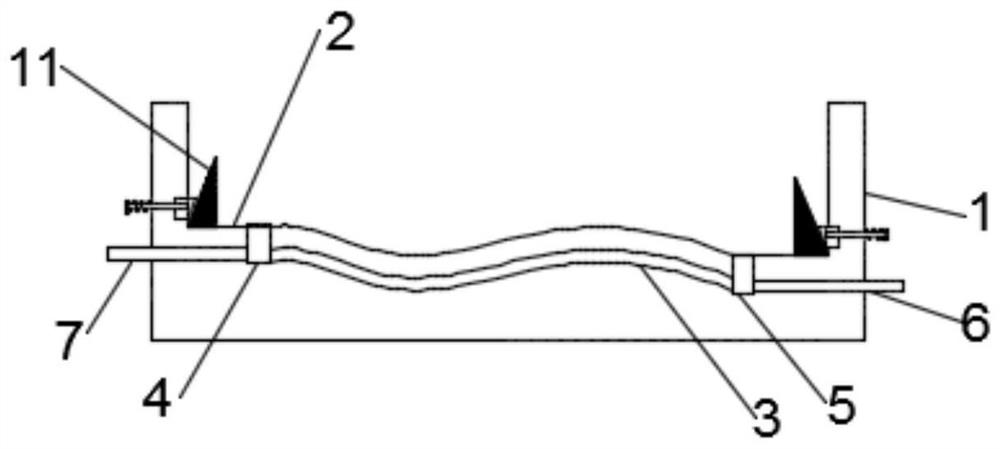

[0023] see Figure 1-3 :

[0024] Step 1: Prepare the lower mold base 1, set up the first processing groove 2 on the lower mold base 1, process the lower mold surface of the target blank film on the bottom wall of the first processing groove 2, and A peripheral side of the processing groove 2 is fixedly connected with a limit ring 11;

[0025] Step 2: pre-embed the lower mold base pipe 3 inside the lower mold base 1 and at the lower side of the first processing tank 2, the lower mold base pipeline 3 is used for cooling medium to facilitate forming The module is cooled and solidified, and the two ends of the lower mold base pipe 3 are respectively connected with the A tee pipe 4 and the B tee pipe 5, and at the free ends of the A tee pipe 4 and the B tee pipe 5 Connect the liquid outlet pipe 6 and the liquid inlet pipe 7 respectively, the free ends of the liquid outlet pipe 6 and the liquid inlet pipe 7 all pass through the side wall of the lower mold base 1, and the external...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap