Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Cooling medium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

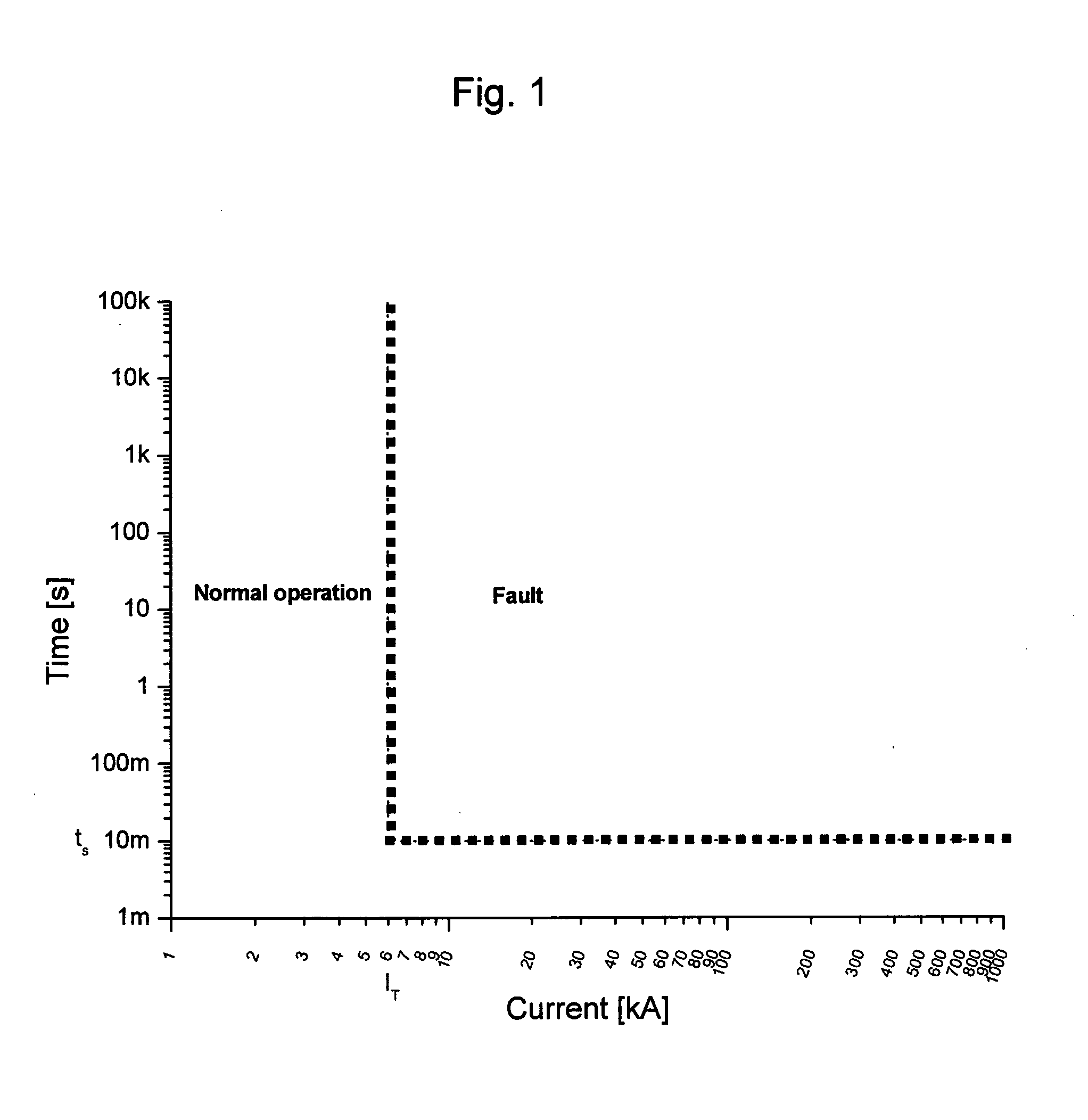

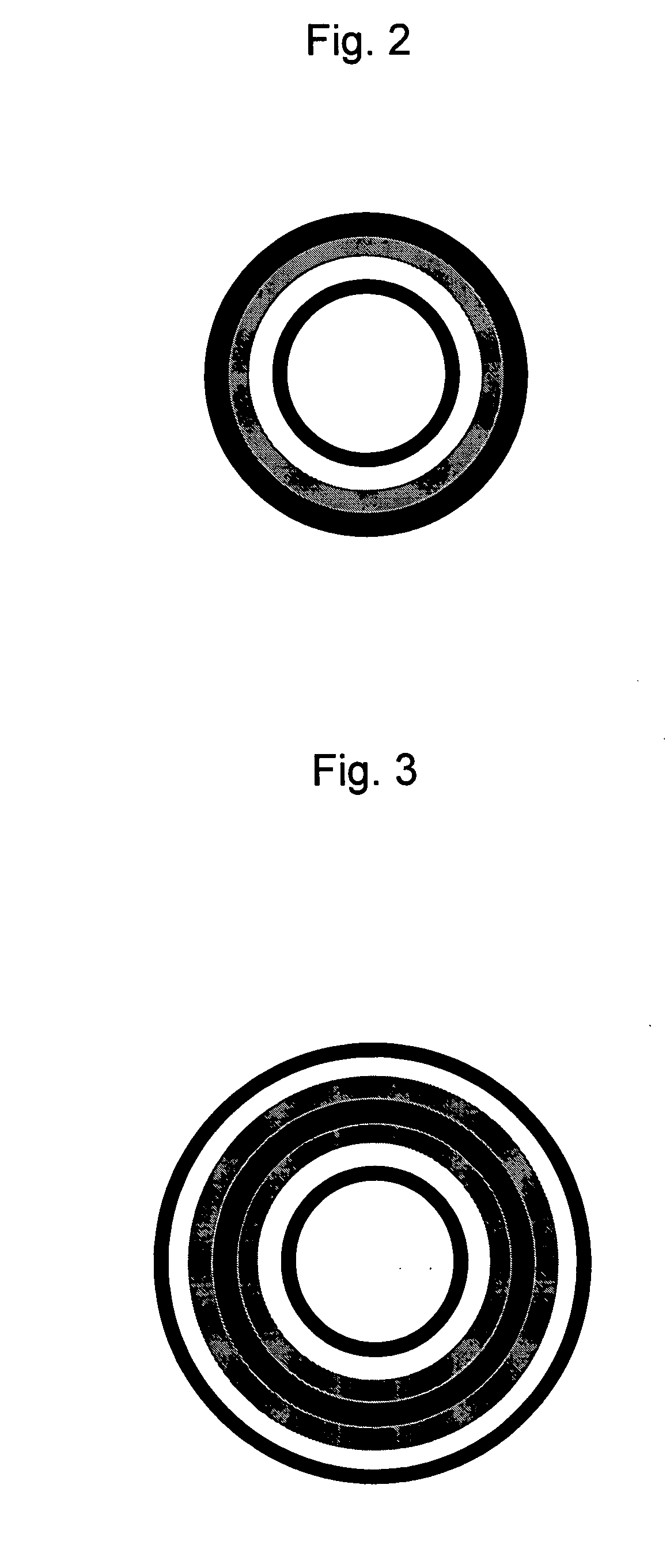

Power cable comprising hts tape(s)

InactiveUS20100179064A1Superconductors/hyperconductorsCable fittings for cryogenic cablesElectricityCooling medium

Owner:NKT CABLES ULTERA

Light appliance and cooling arrangement

InactiveUS7182484B2Improve cooling effectLighting applicationsMechanical apparatusAerospace engineeringCooling medium

Owner:S R SMITH

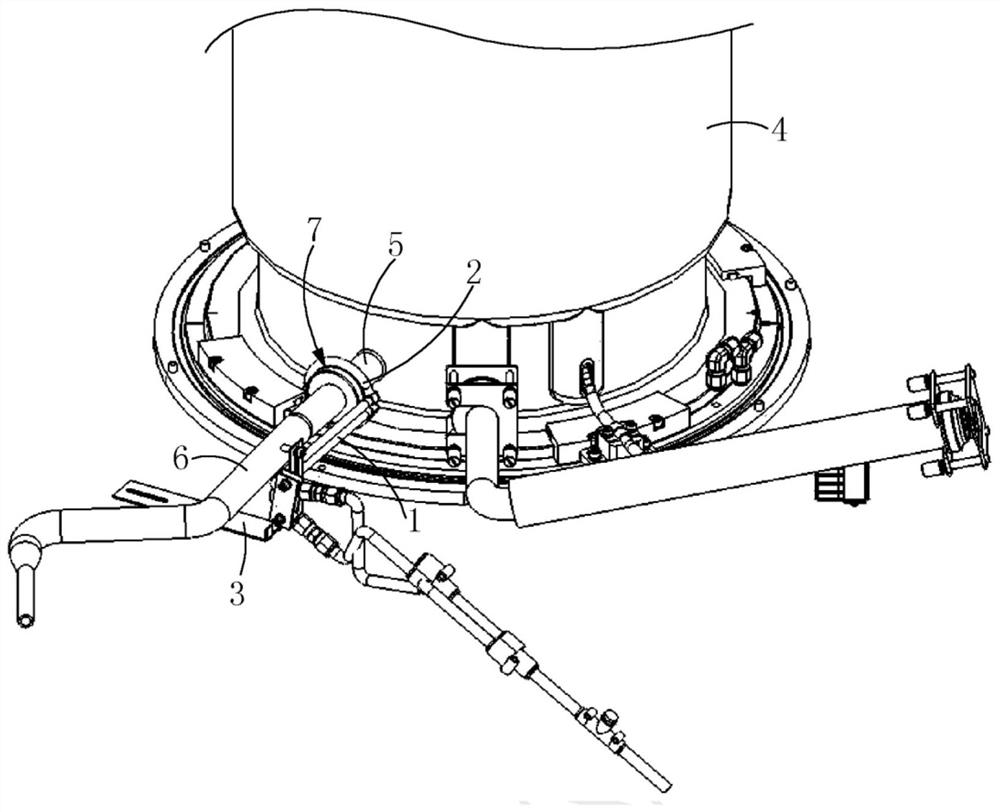

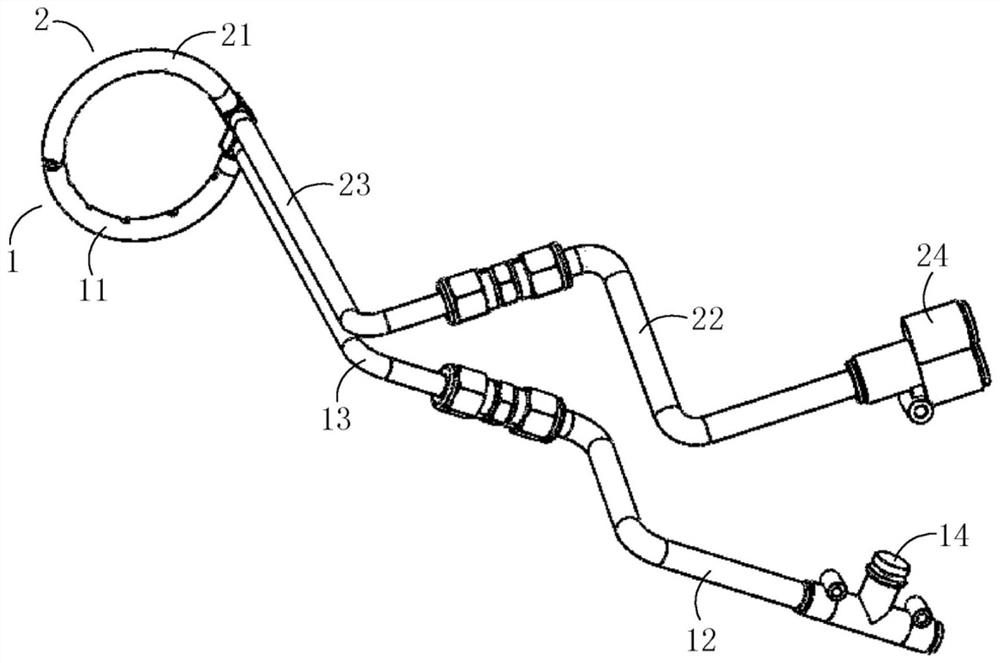

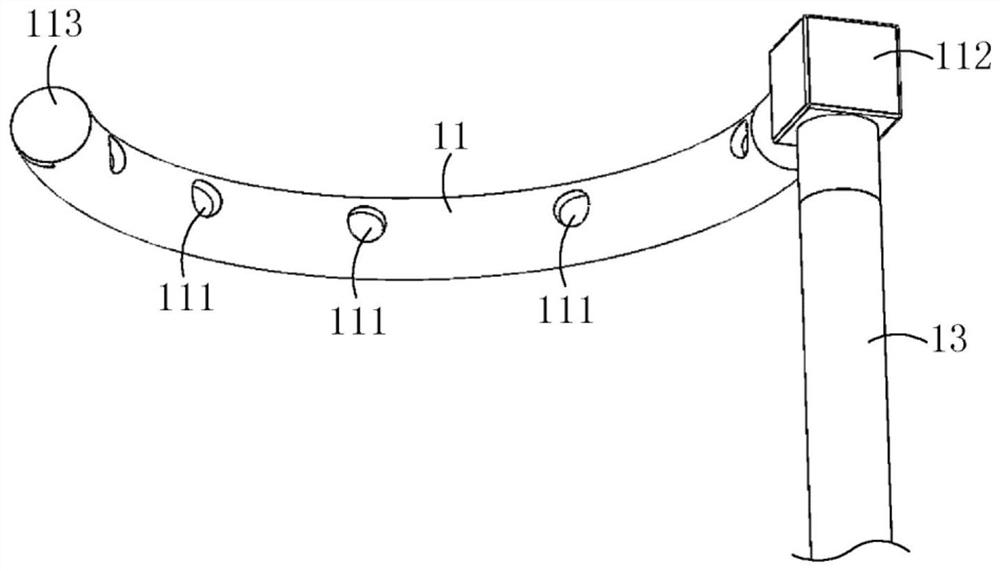

Motor stator heat radiation structure

InactiveCN105356671AGuaranteed cooling effectImprove thermal conductivityCooling/ventillation arrangementSupports/enclosures/casingsConductor CoilCooling pipe

Owner:HEFEI JUYI POWER SYST CO LTD

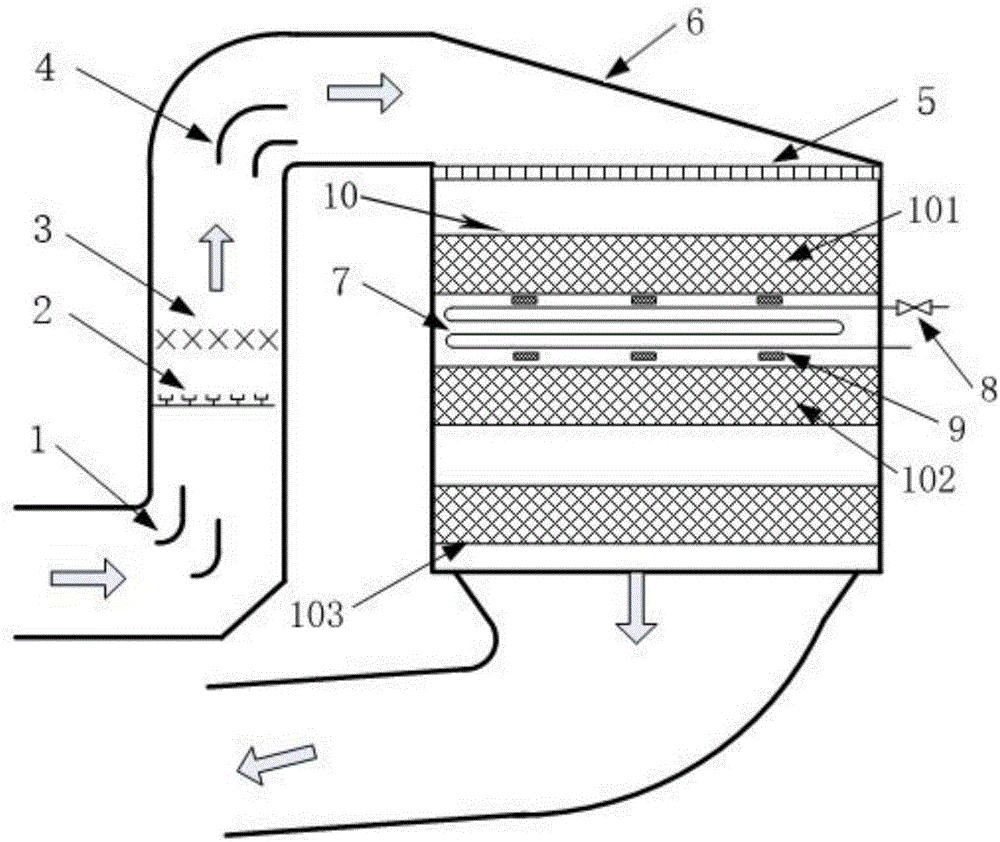

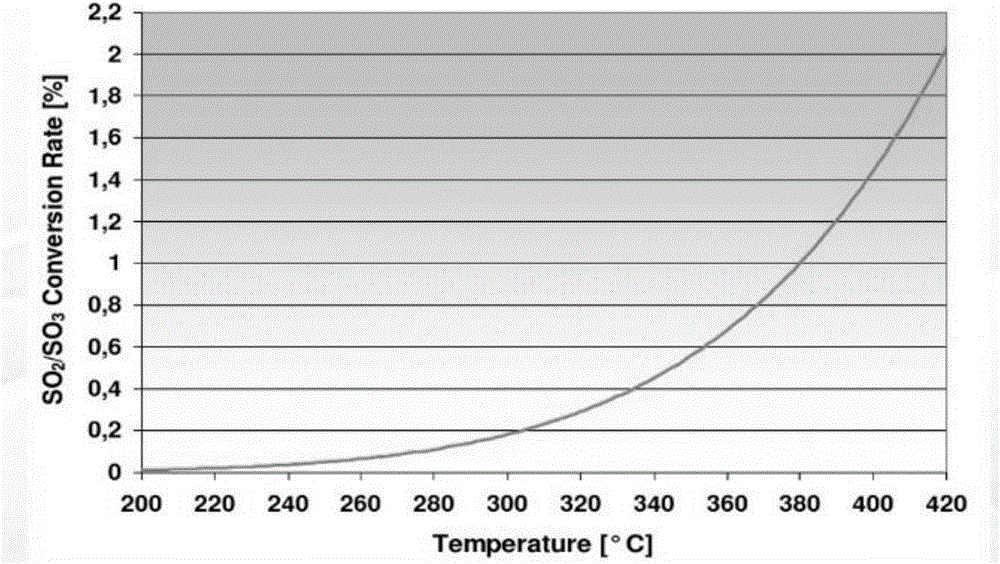

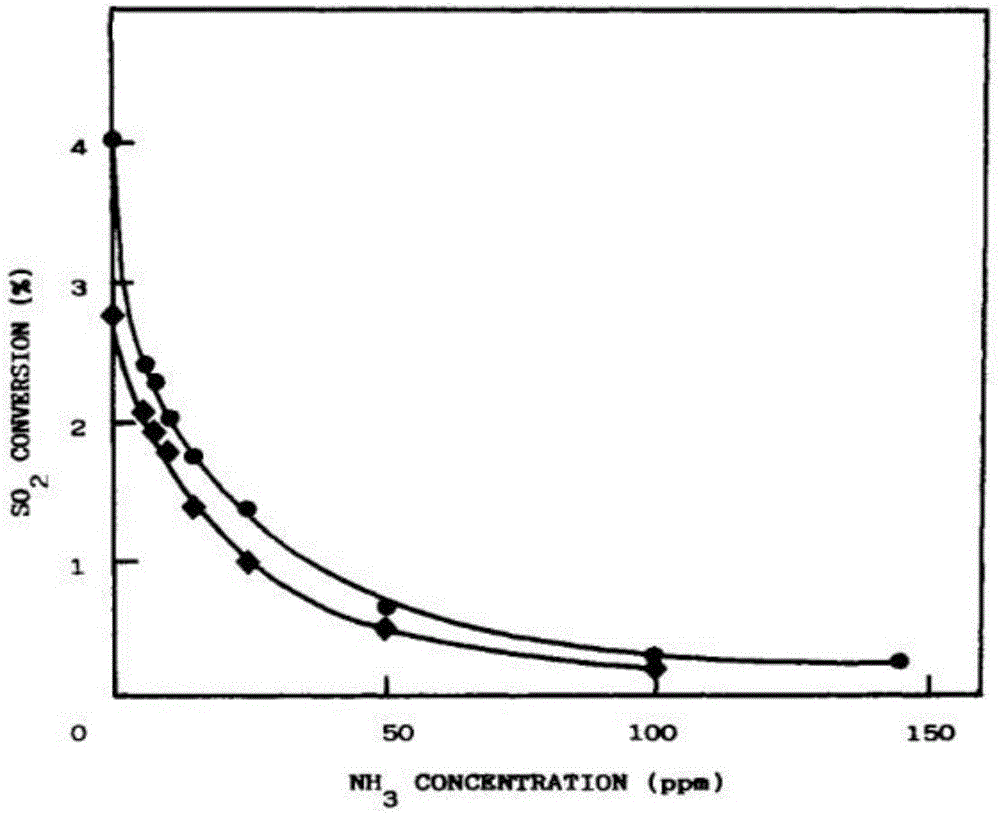

SCR denitration system with low SO2/SO3 conversion rate

InactiveCN106178950AReasonable structureEasy to installDispersed particle separationFlue gasEngineering

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

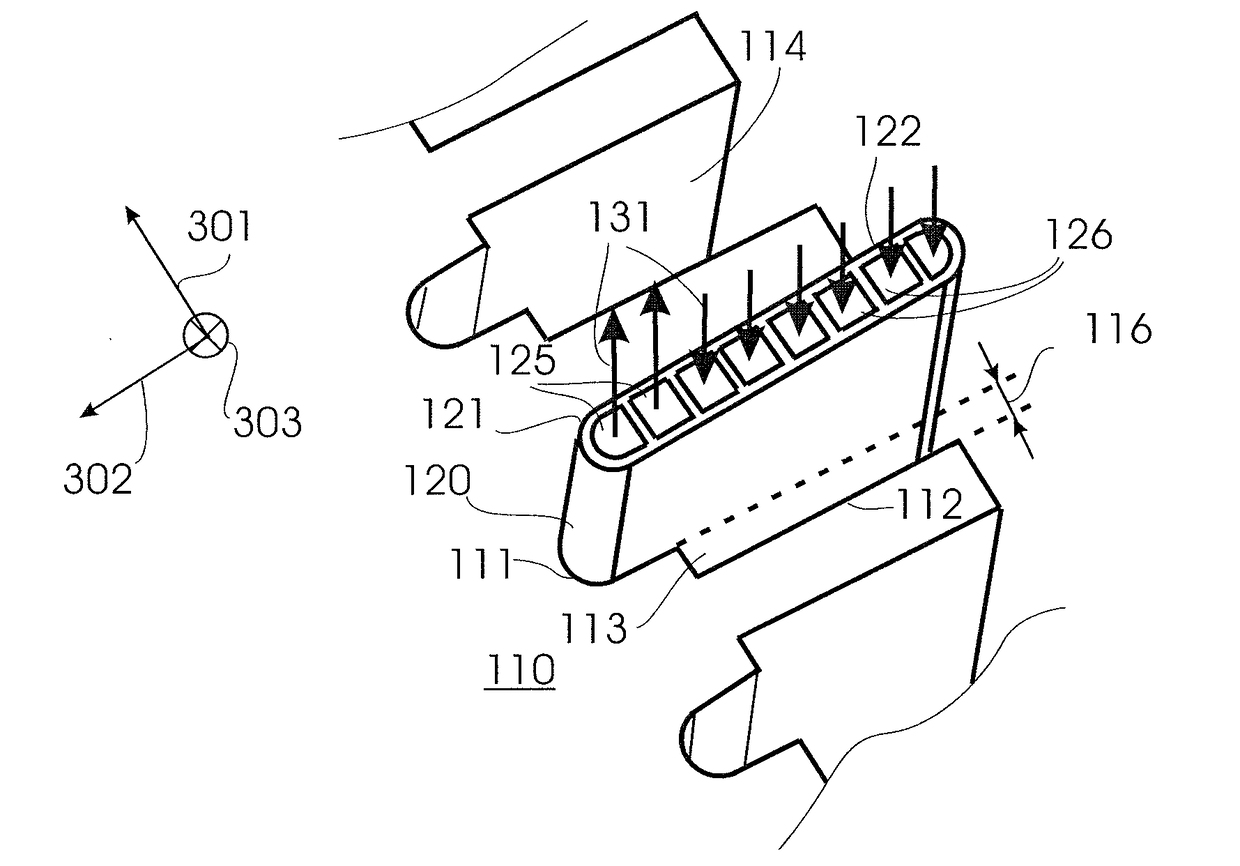

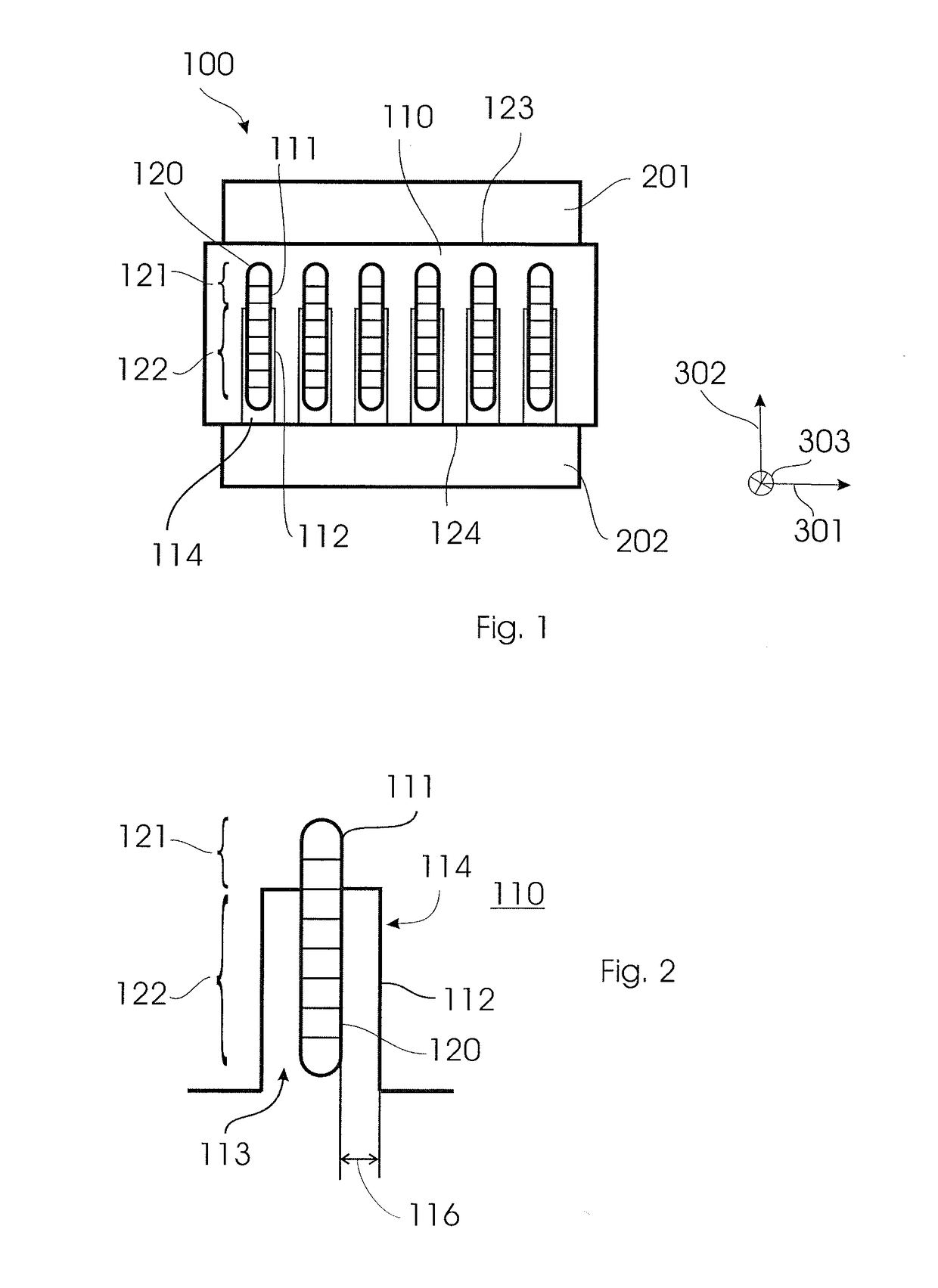

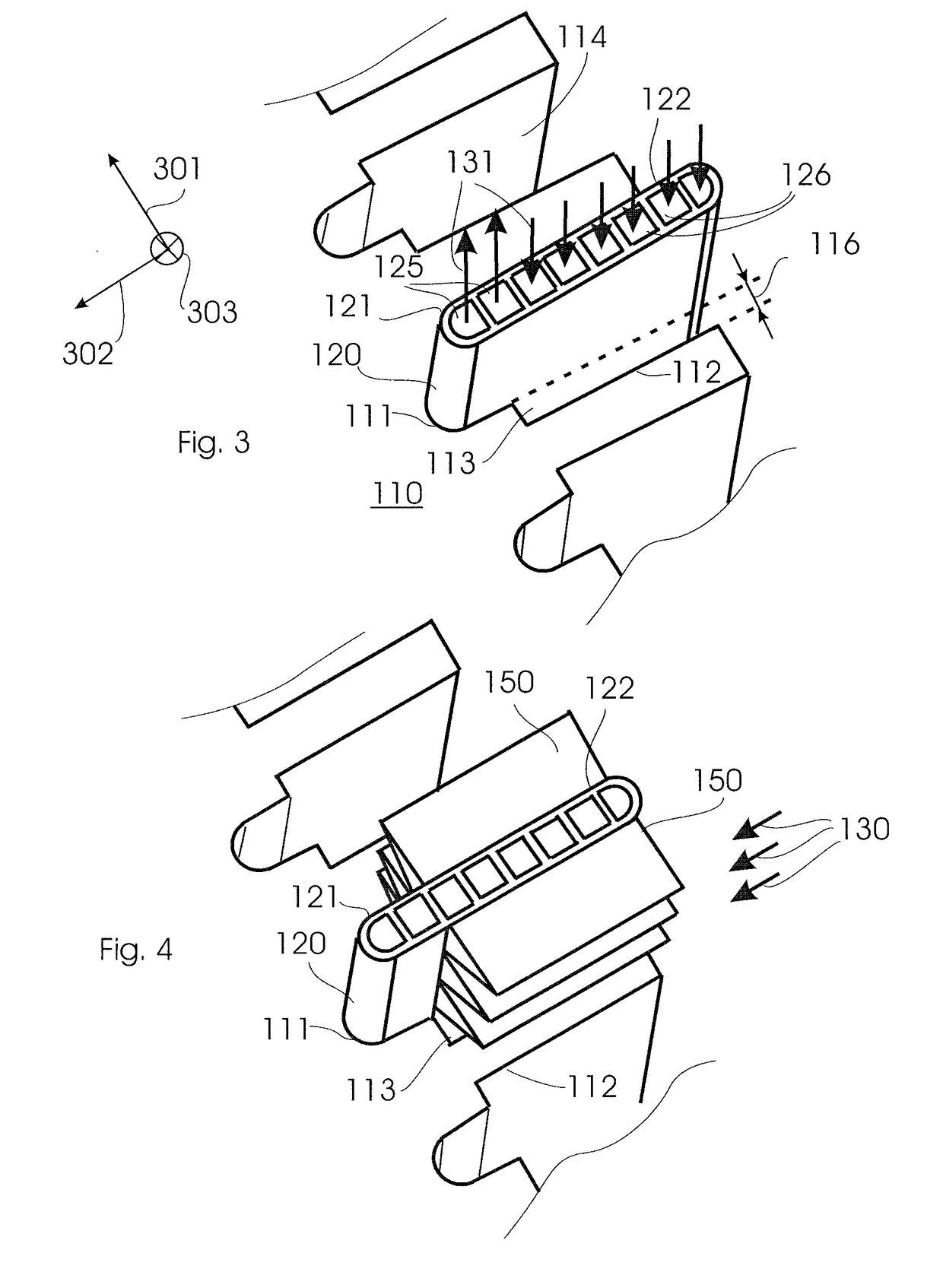

Heat exchanger for power-electronic components

ActiveUS20170202108A1Improve cooling effectReduce filter sizeThermal insulationIndirect heat exchangersEngineeringElectronic component

Owner:ABB (SCHWEIZ) AG

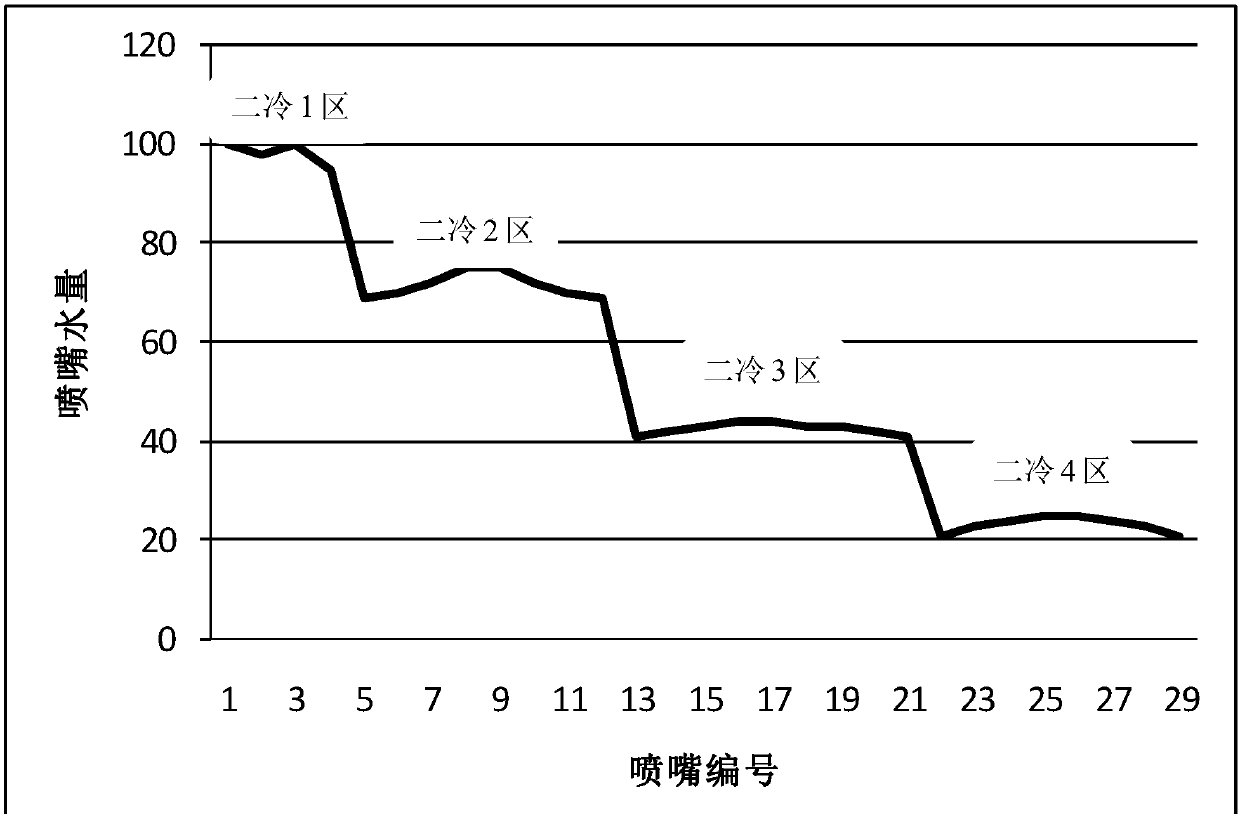

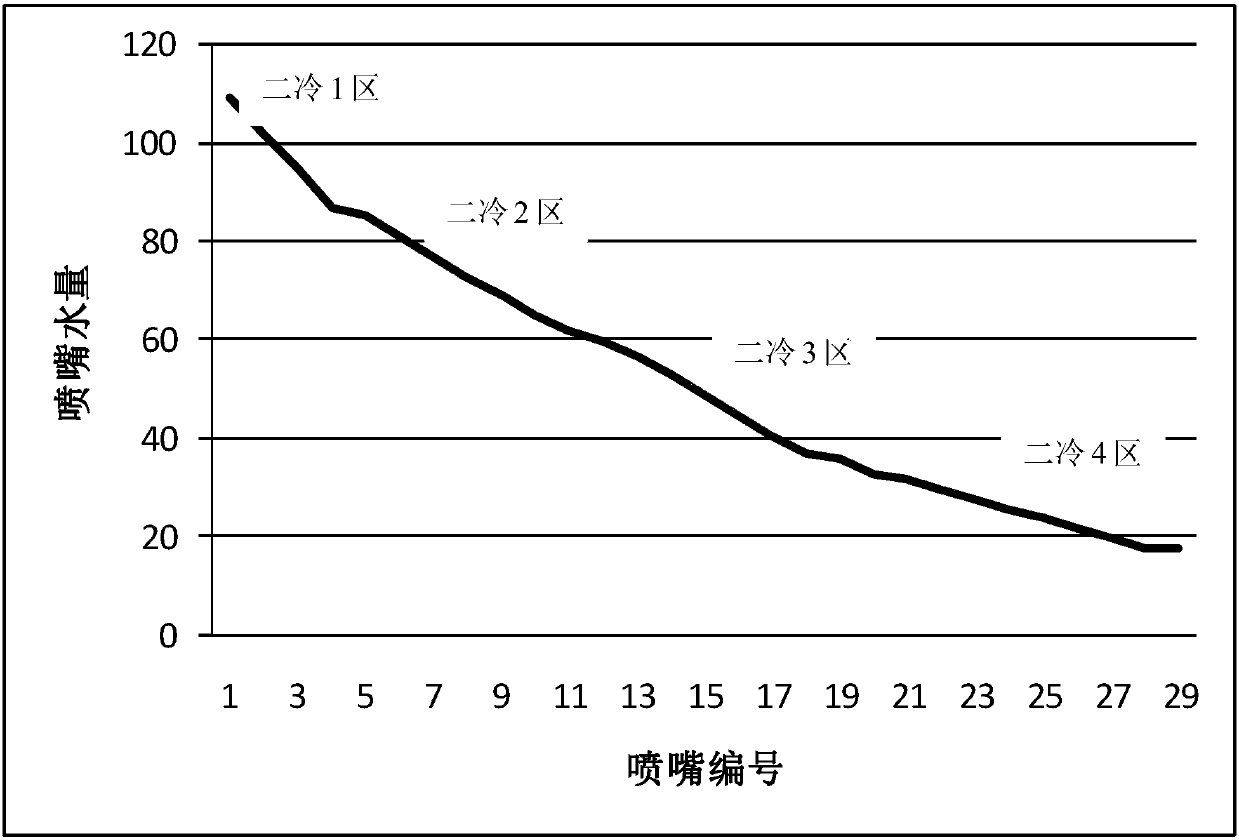

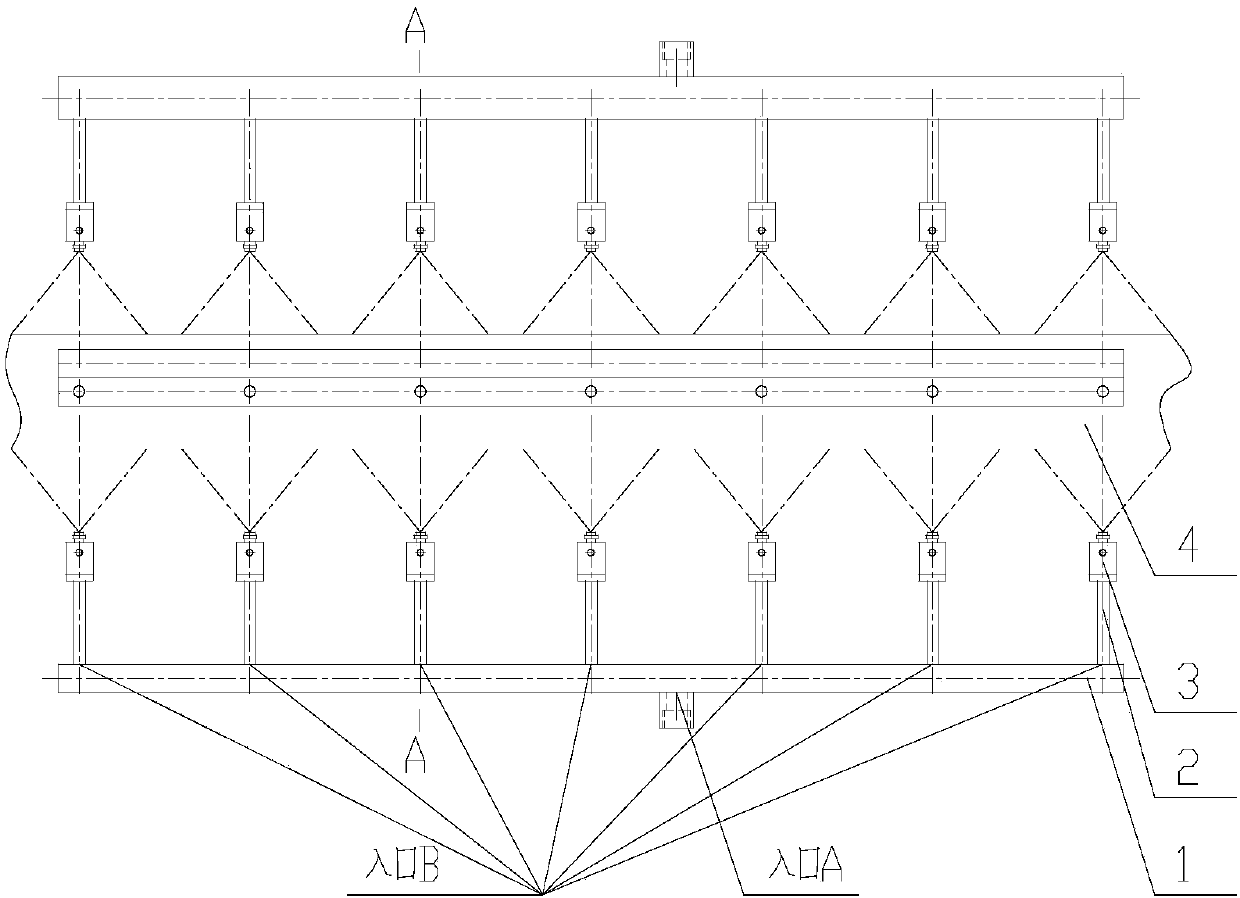

Secondary cooling method and device for continuous casting machine

PendingCN107737896AControl and regulate outflow flowImprove cooling uniformityThermodynamicsSpray nozzle

Owner:CISDI ENG CO LTD +1

Processing technology of maca superfine powder

InactiveCN106509709AImprove dissolution rateHigh dissolution rateFood freezingFood shapingFreeze thawingBULK ACTIVE INGREDIENT

Owner:北京桔色控股集团股份有限公司 +1

Heat dissipation measuring method for electromechanical equipment

Owner:DALIAN MARITIME UNIVERSITY

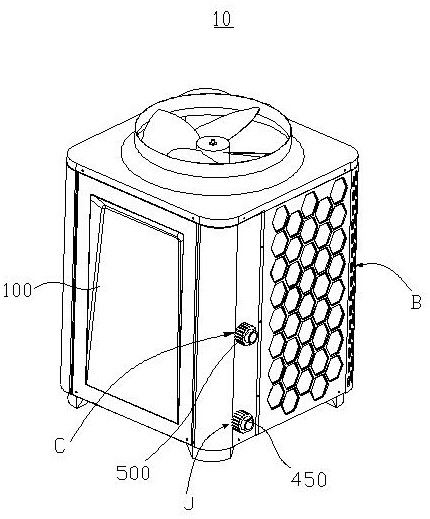

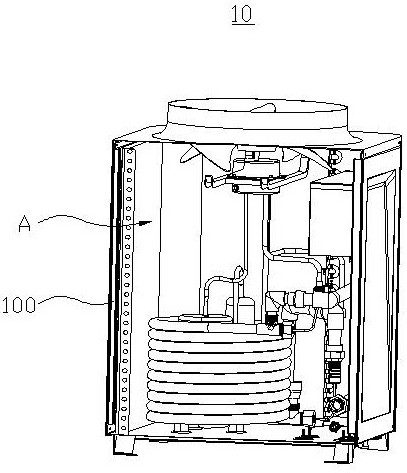

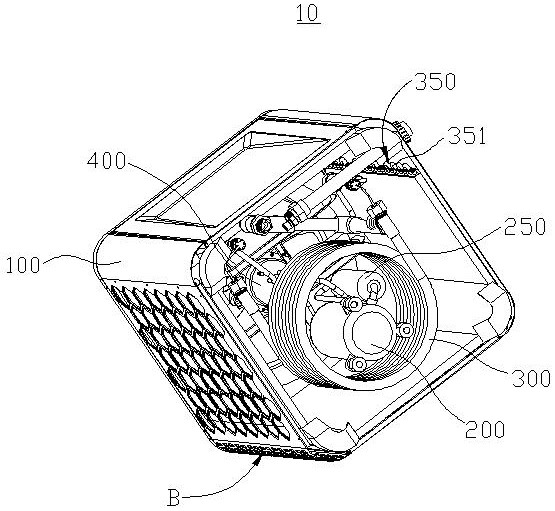

Air conditioner unit and air conditioning system

InactiveCN111928391AReduce lossImprove evaporation efficiencyHeating and ventilation casings/coversEvaporators/condensersVapor–liquid separatorWater vapor

Owner:深圳市中鼎空调净化有限公司

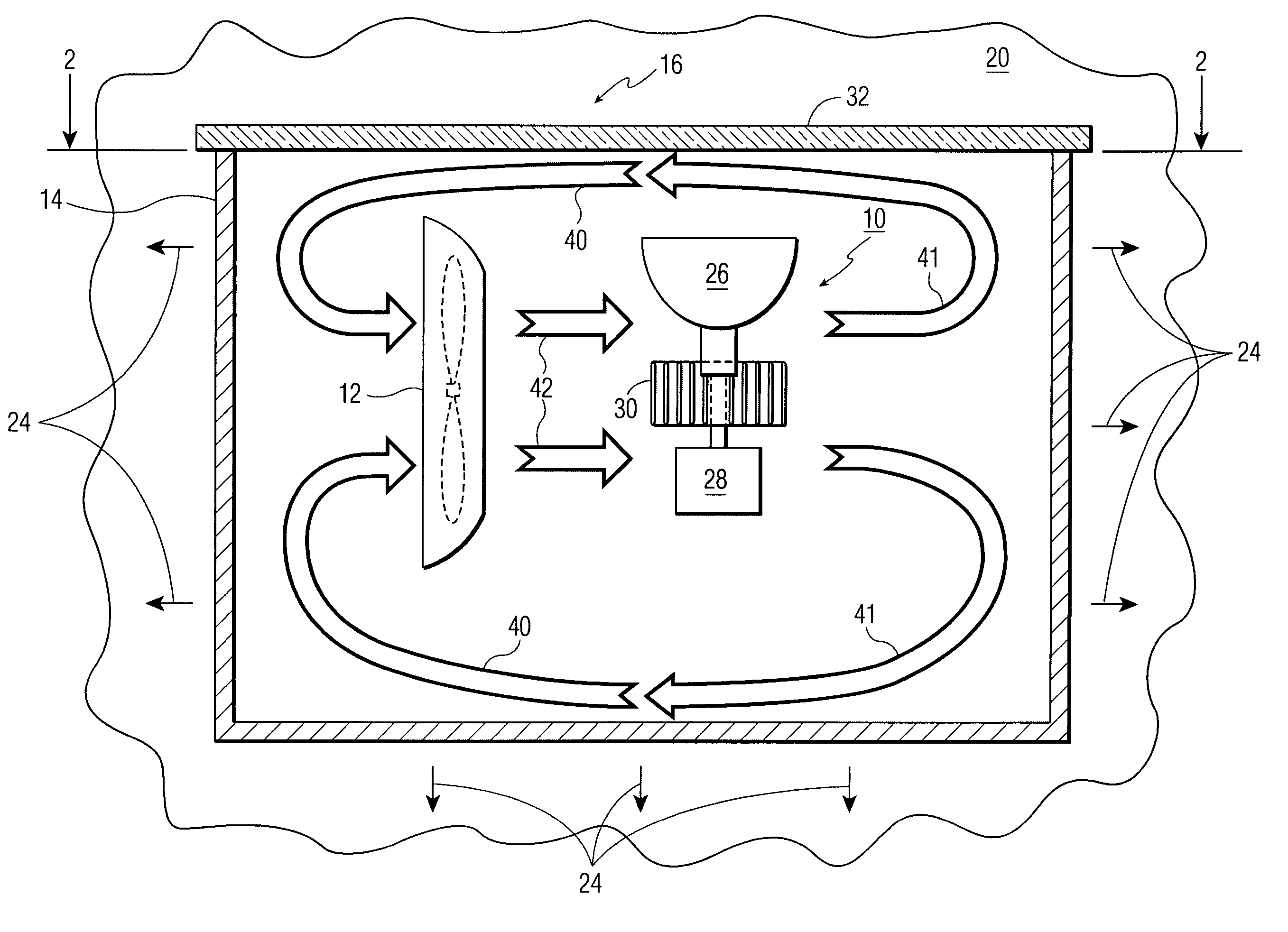

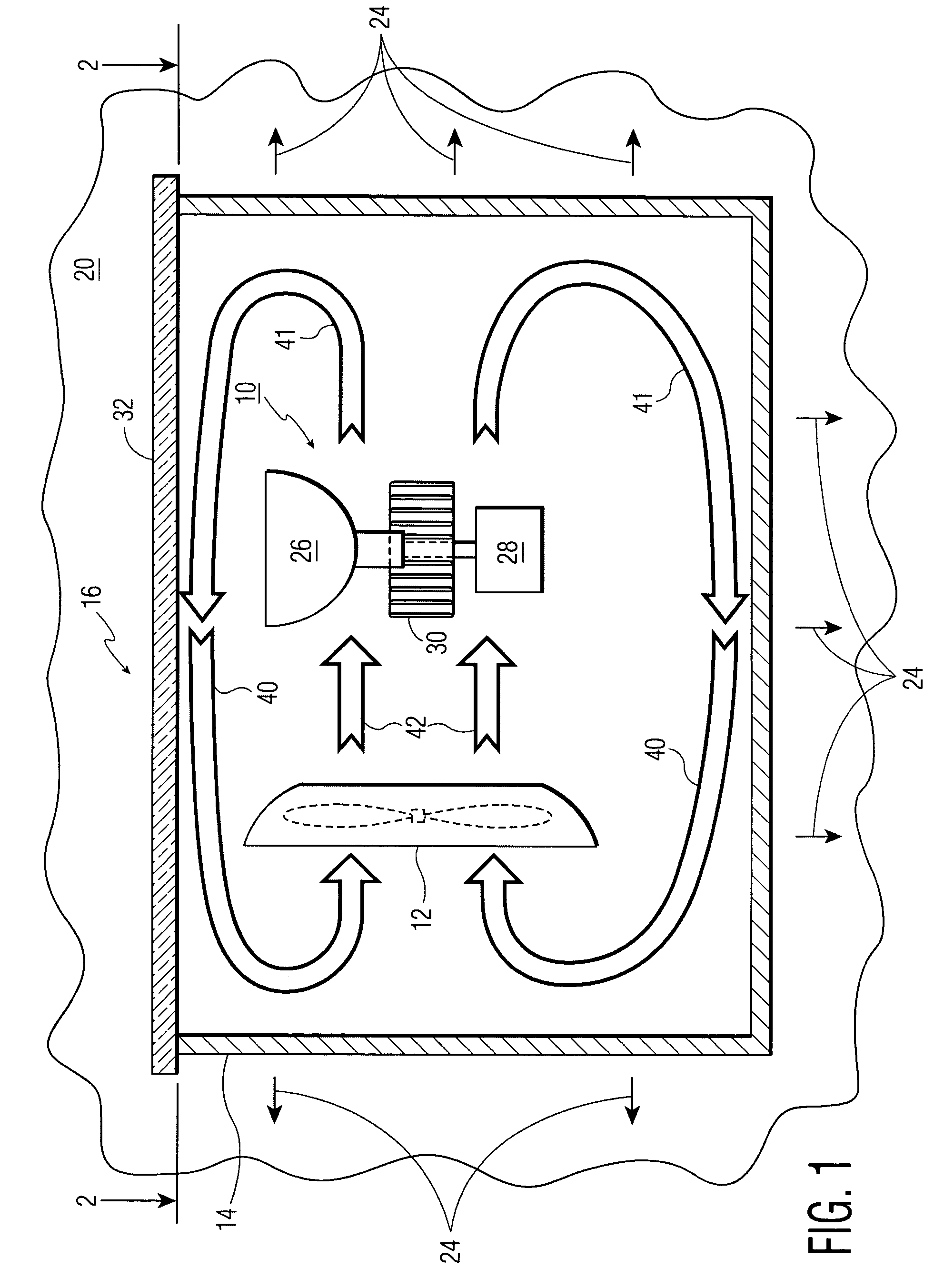

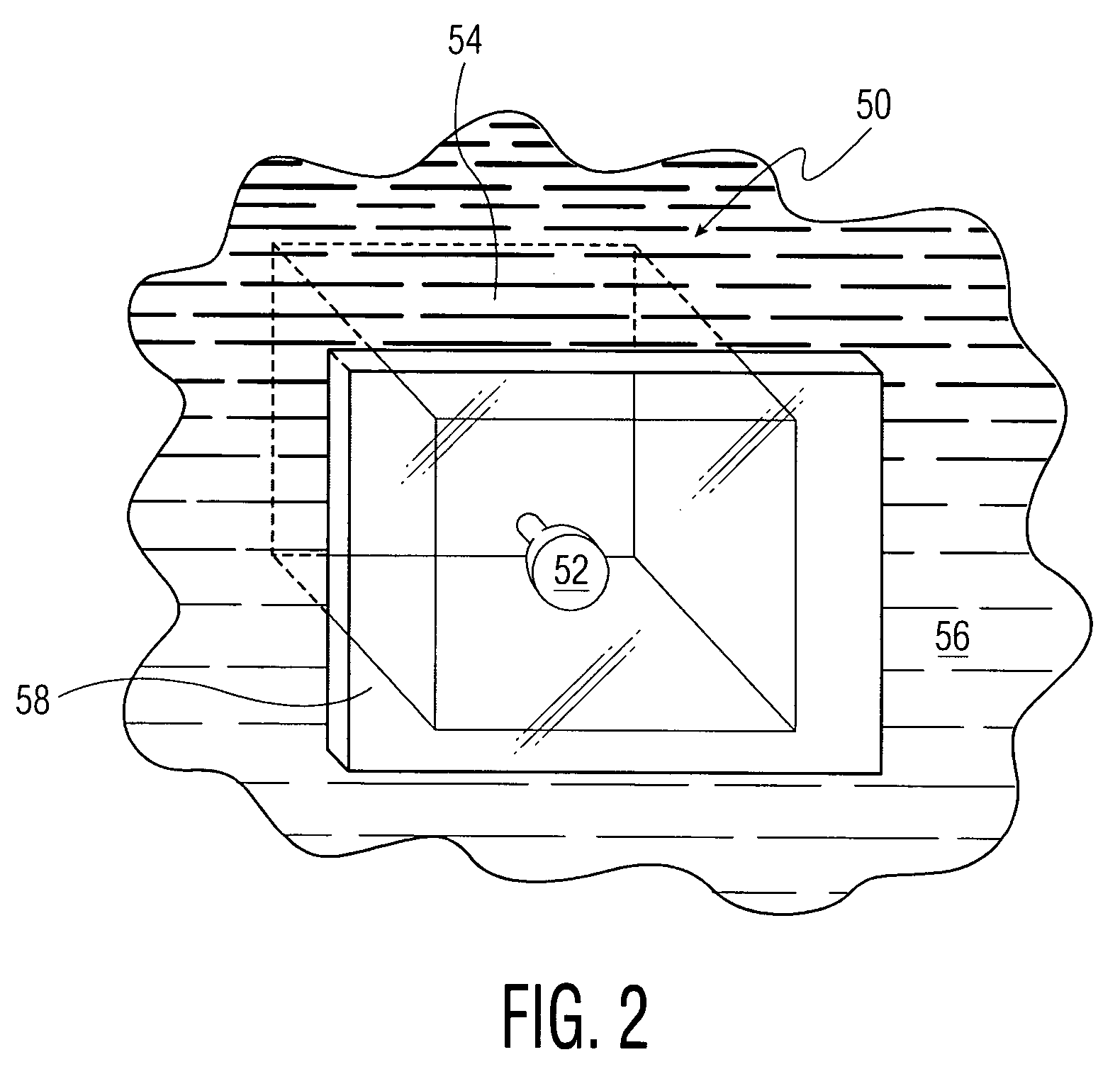

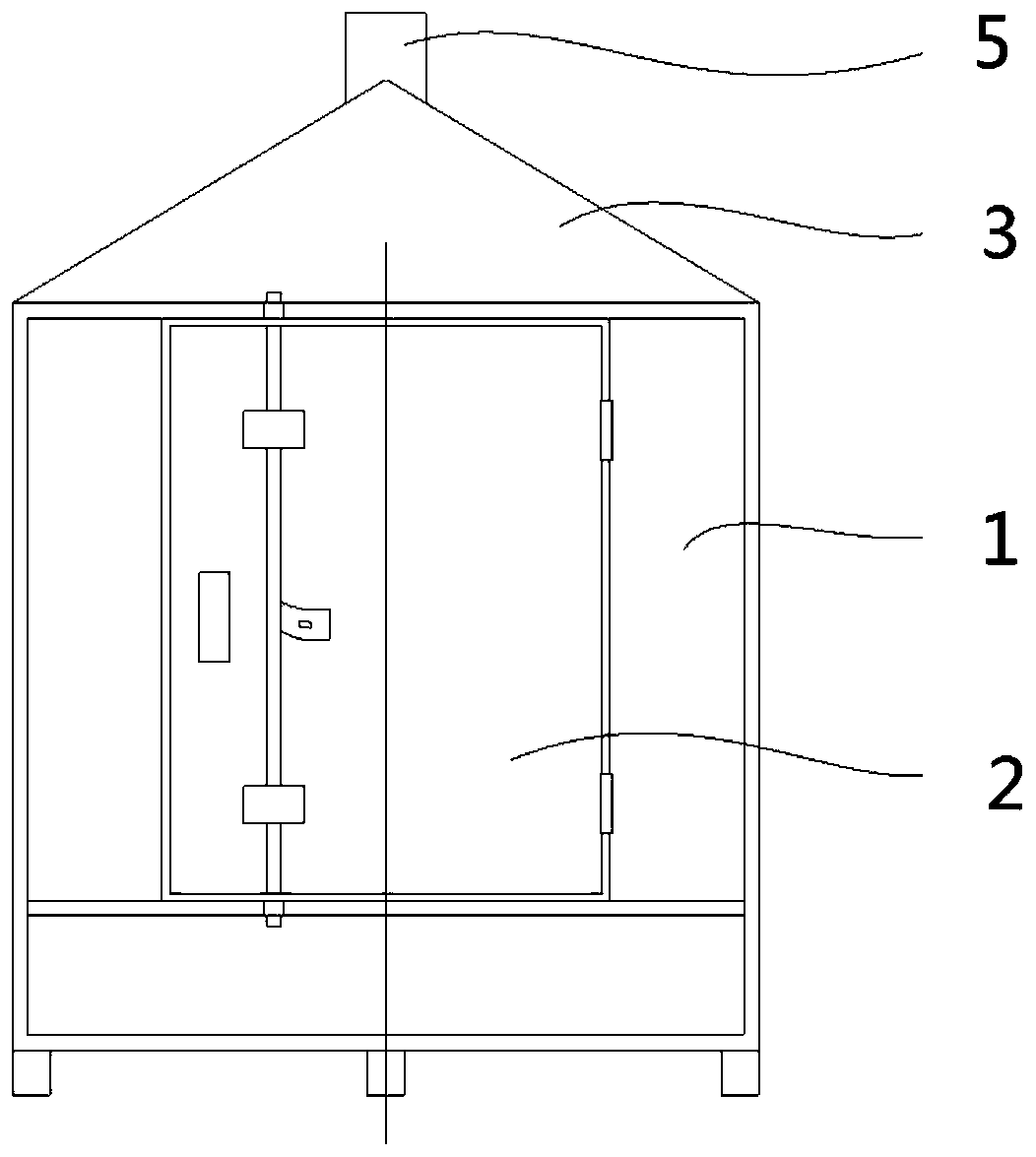

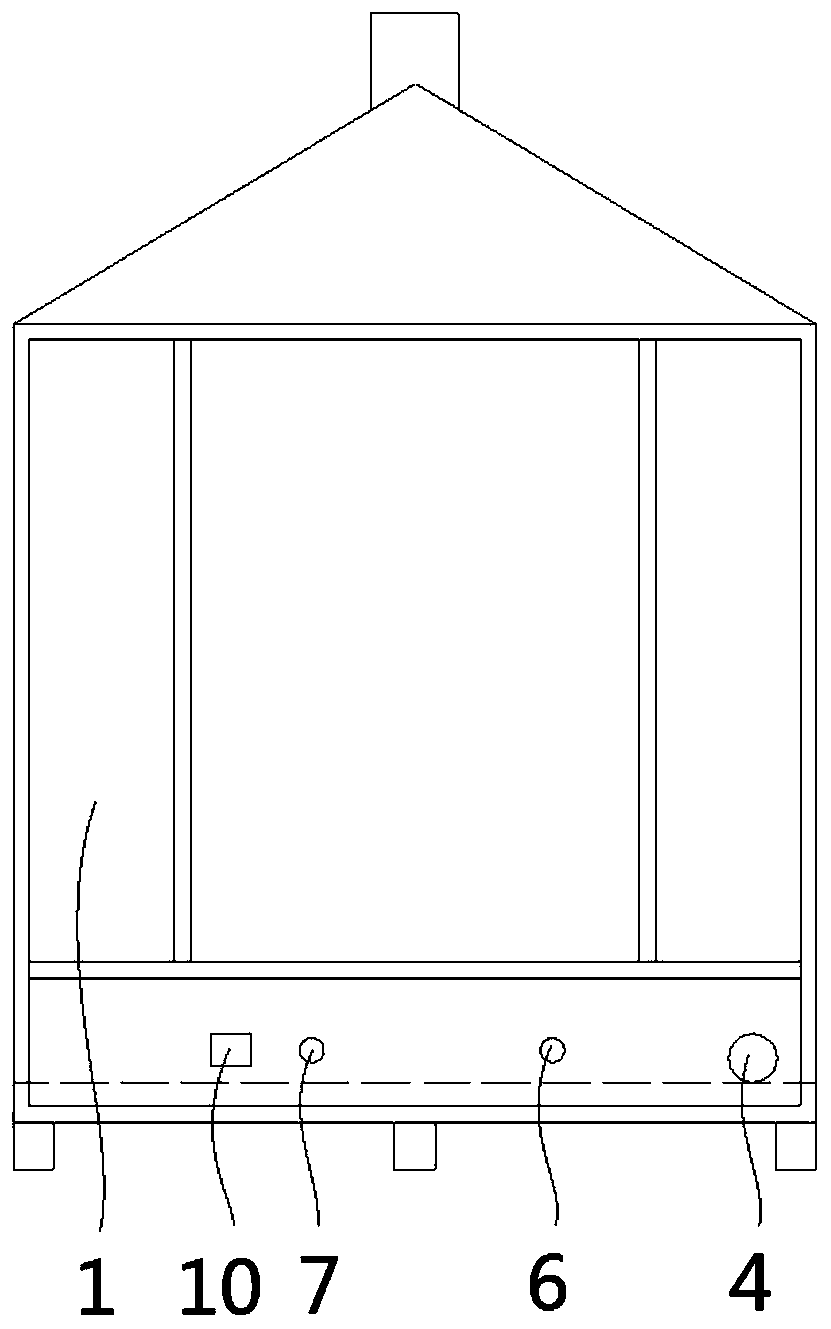

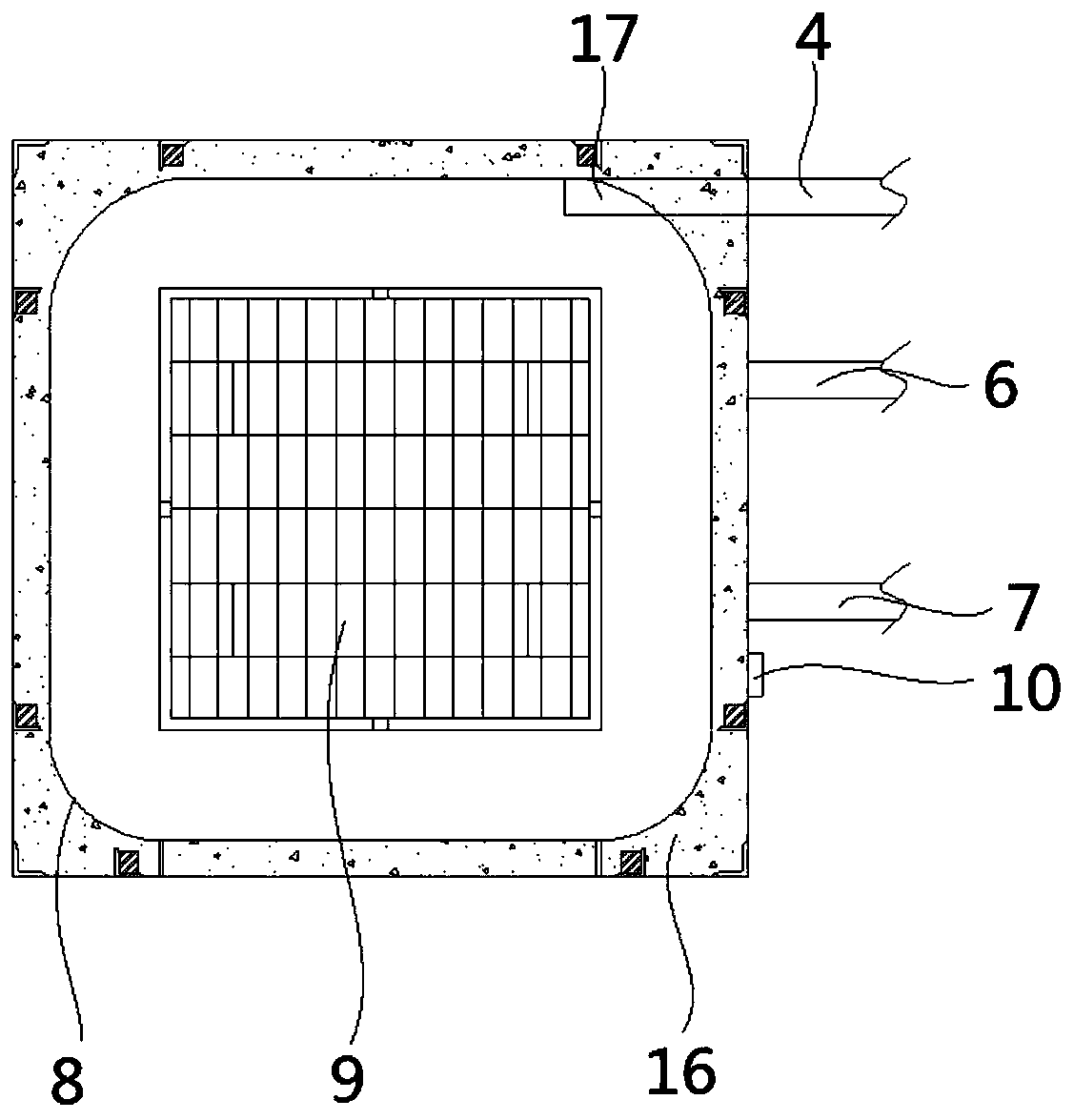

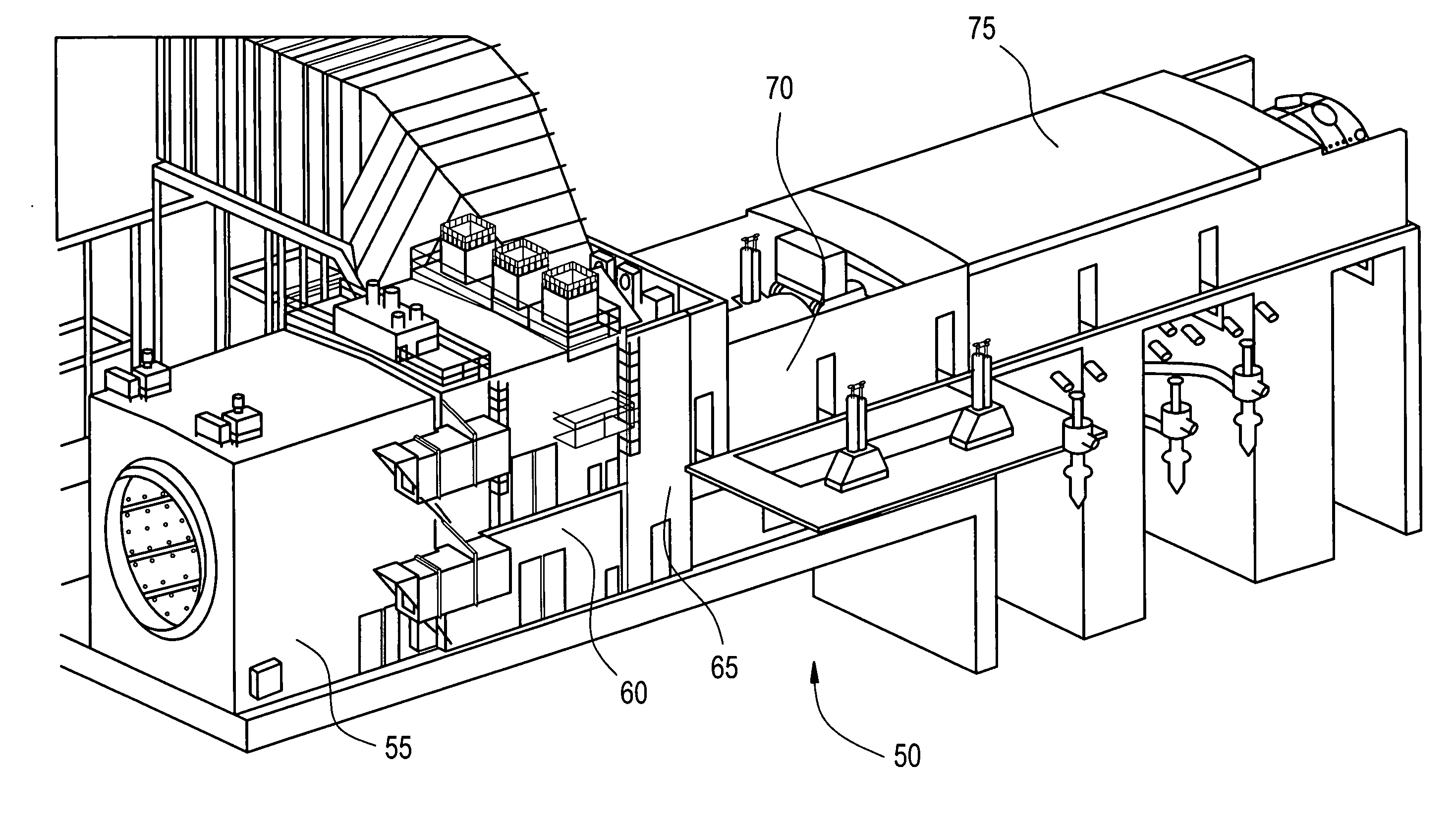

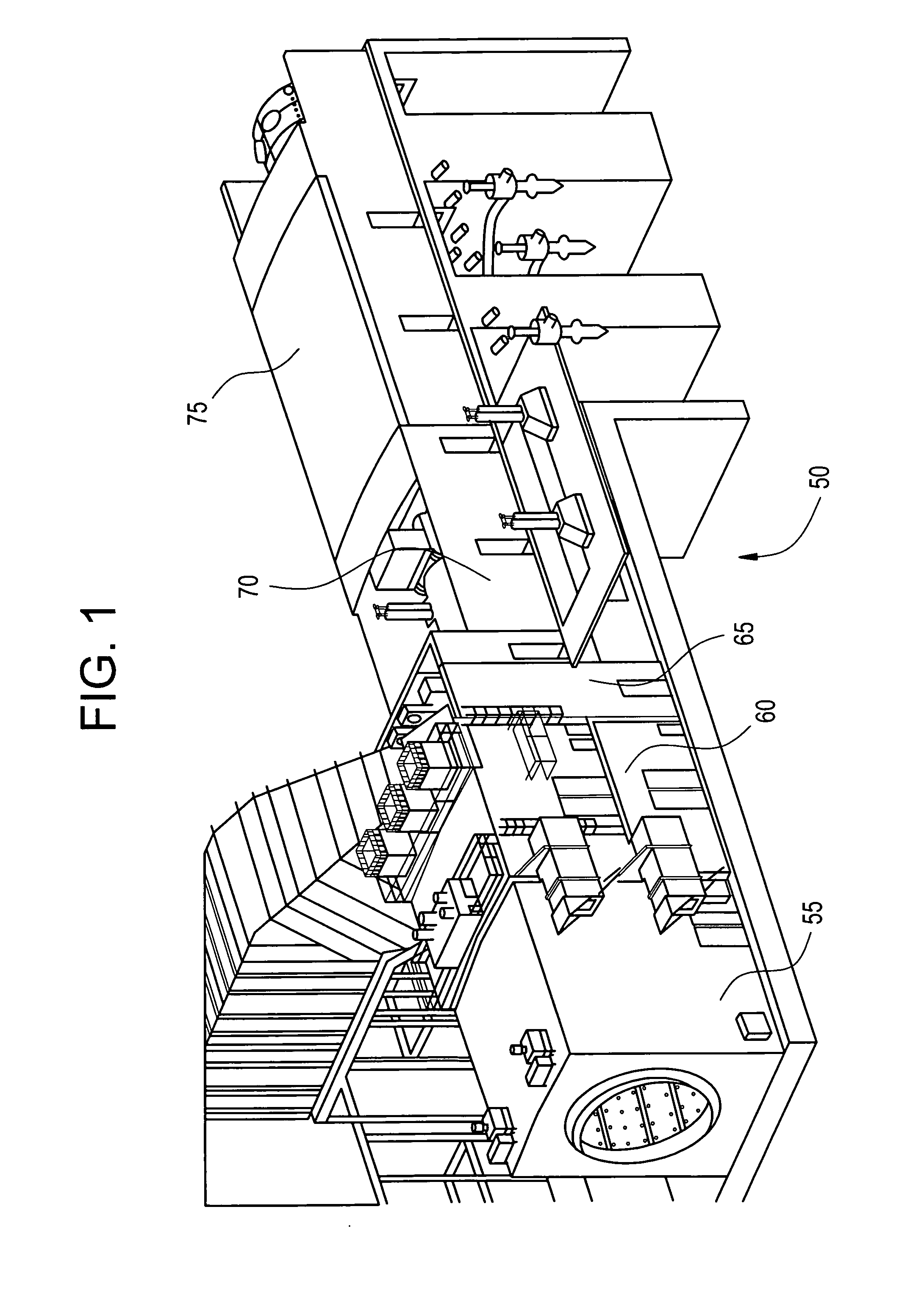

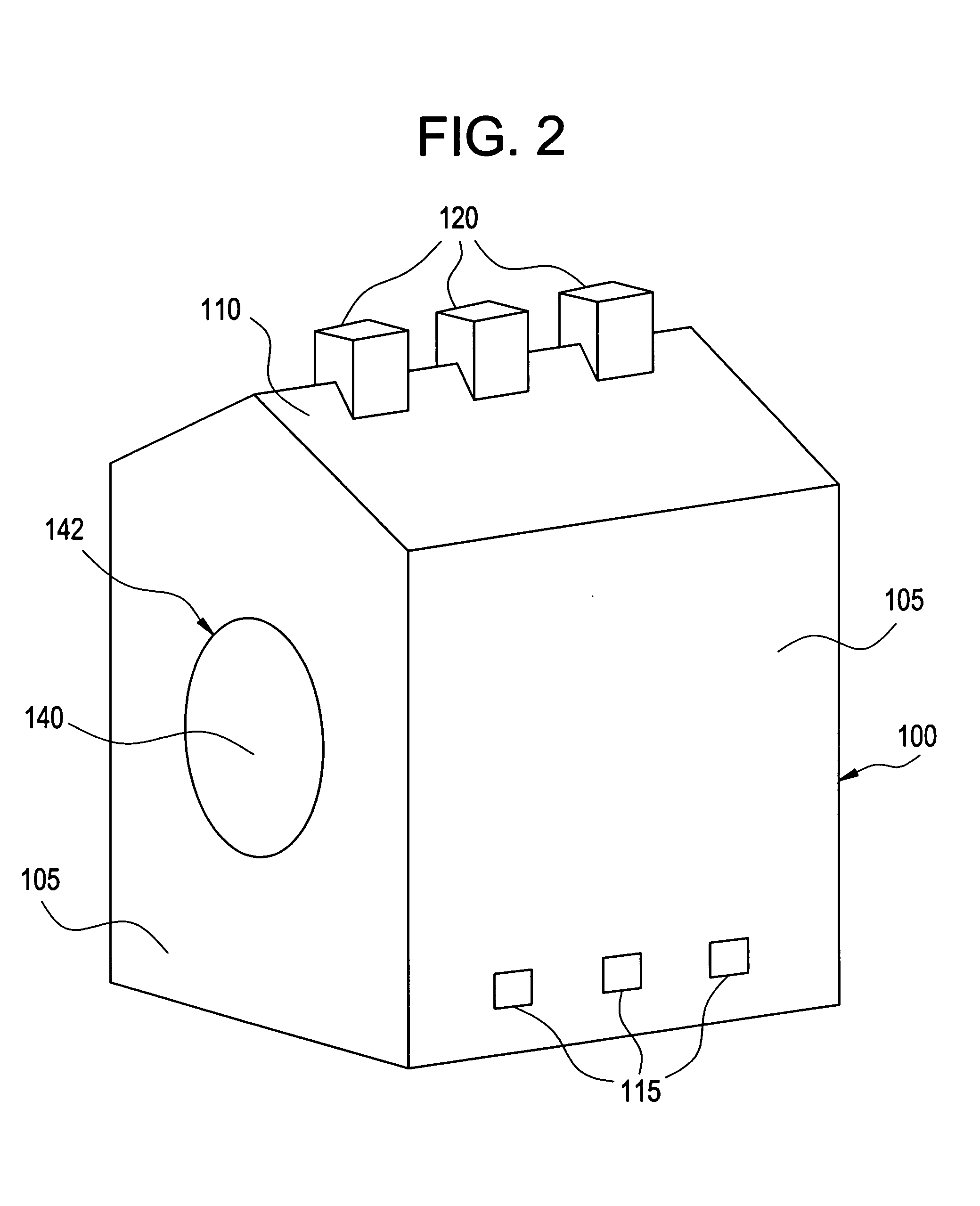

System and apparatus for enclosing equipment

InactiveUS20070249279A1Lighting and heating apparatusMachines/enginesElectrical and Electronics engineeringCooling medium

Owner:GENERAL ELECTRIC CO

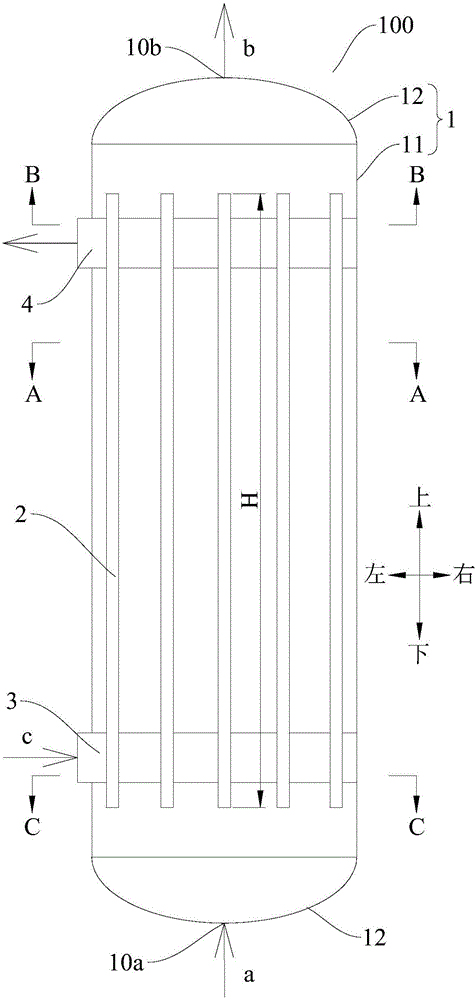

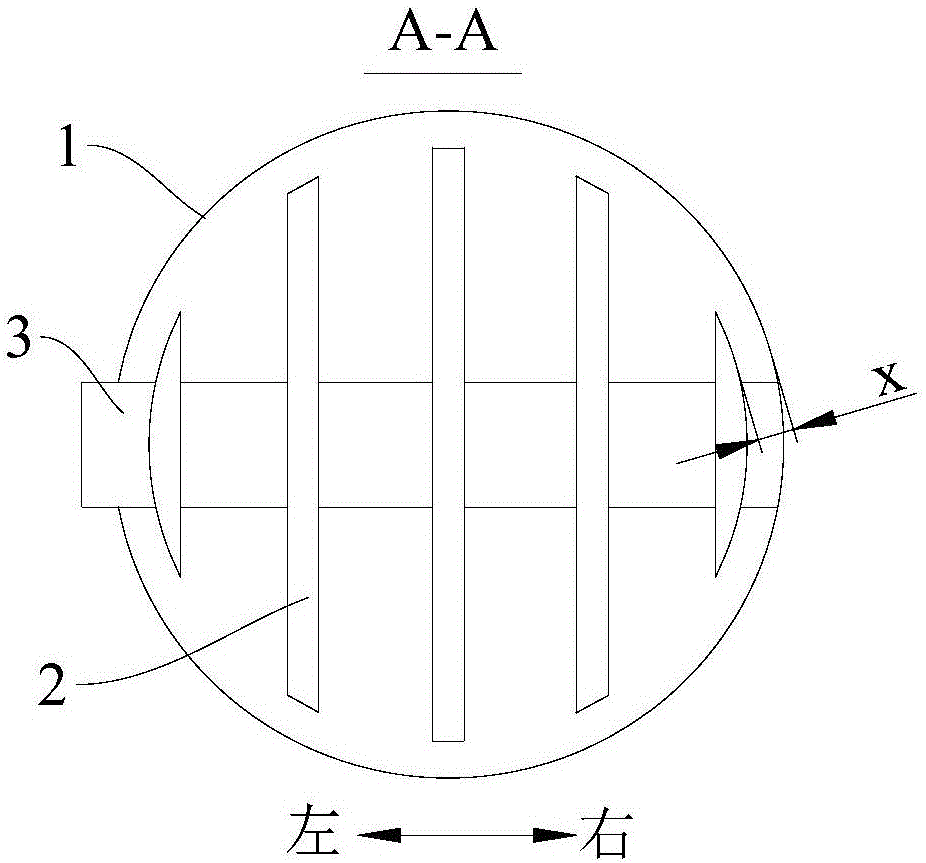

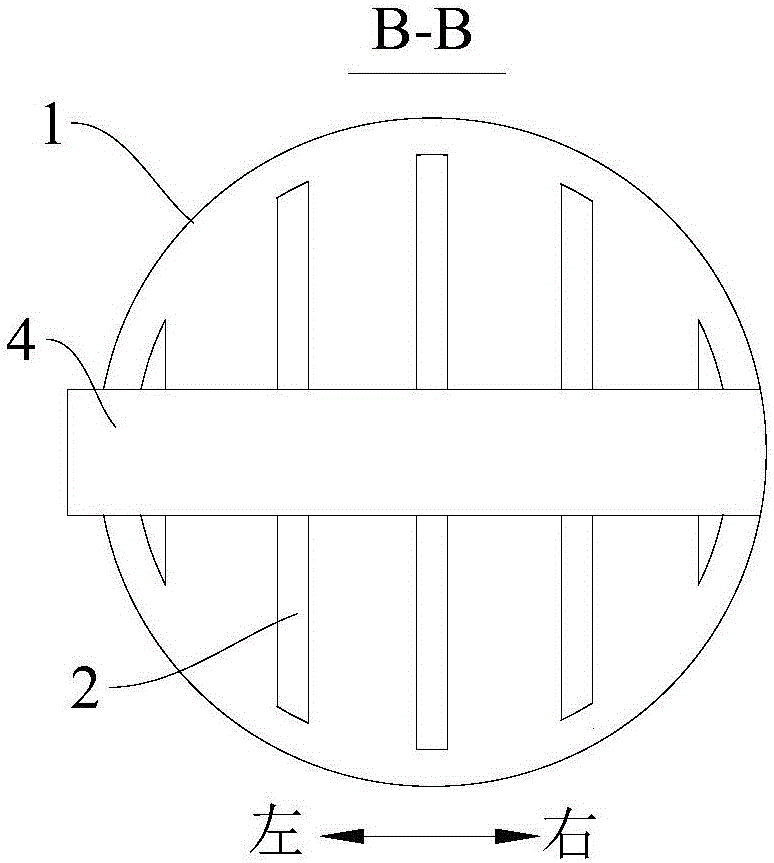

Slurry bed reactor

PendingCN106824021AStable temperatureIncrease the heat exchange areaChemical/physical processesProcess engineeringSlurry

Owner:SHENWU TECH GRP CO LTD

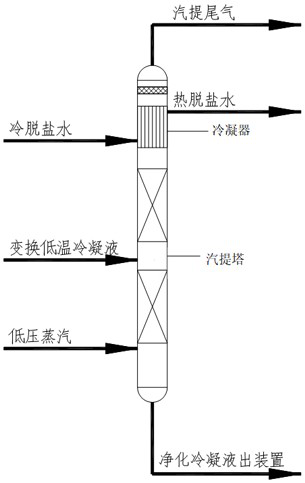

Coal chemical industry conversion low-temperature condensate steam stripping process

ActiveCN111744227AThorough strippingGood stripping effectDistillation regulation/controlVapor condensationCoal chemical industryPetroleum engineering

Owner:EAST CHINA ENG SCI & TECH

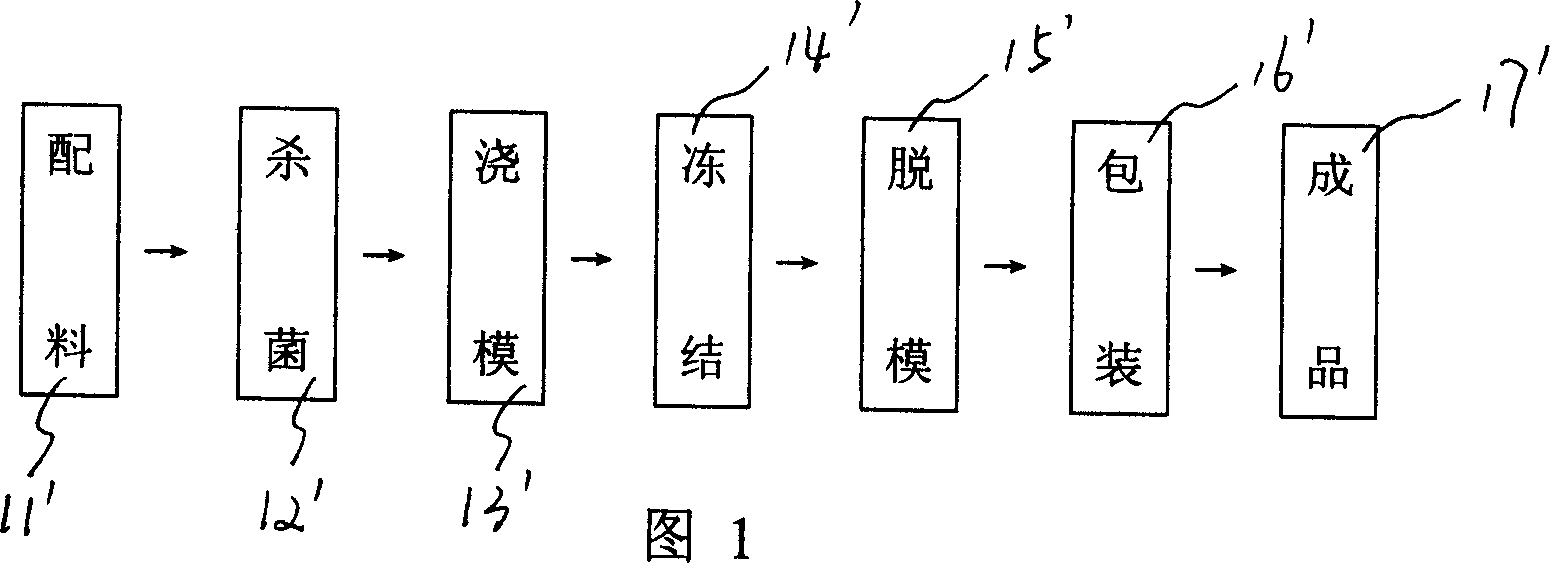

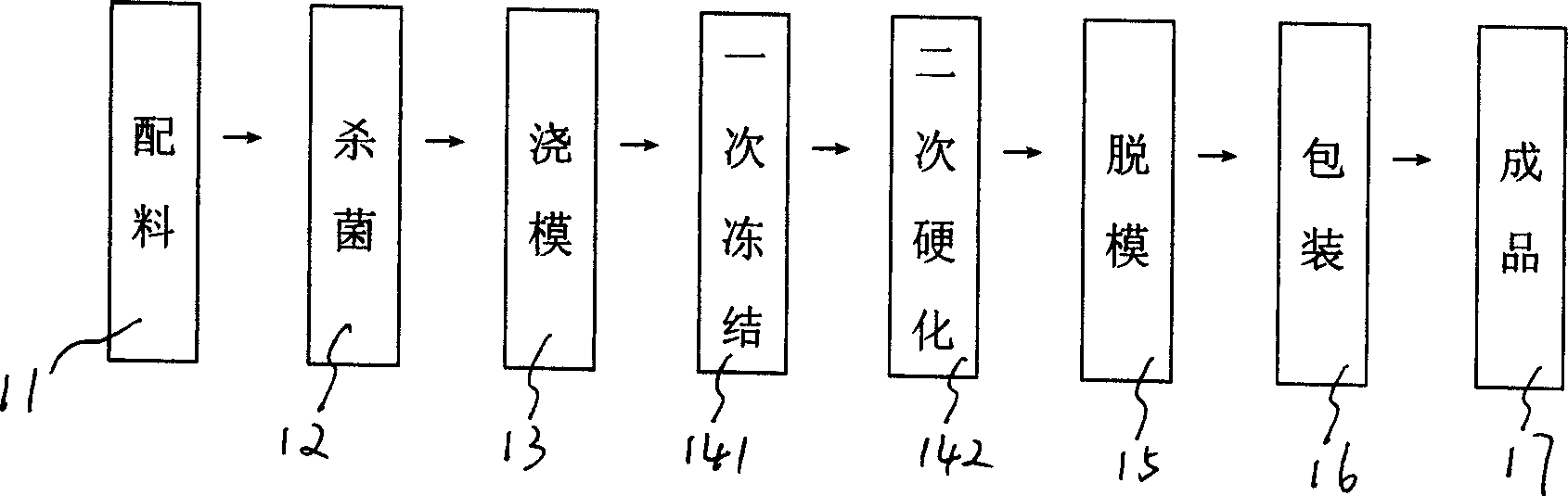

A cold drink preparation method

Owner:张军

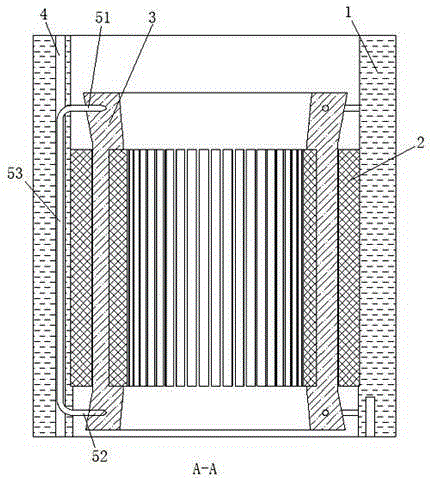

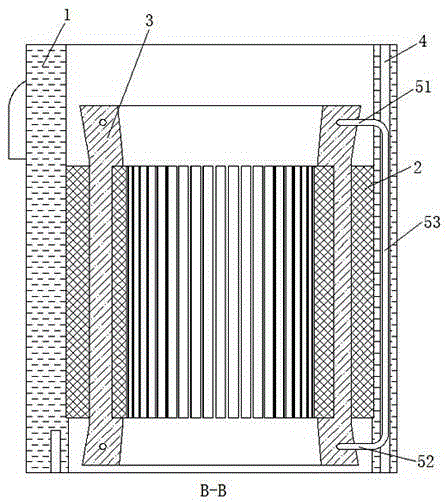

Cooling devices, semiconductor processing chambers and equipment

ActiveCN110610878BAvoid seal failureImprove sealingSemiconductor/solid-state device manufacturingThermodynamicsProcess engineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

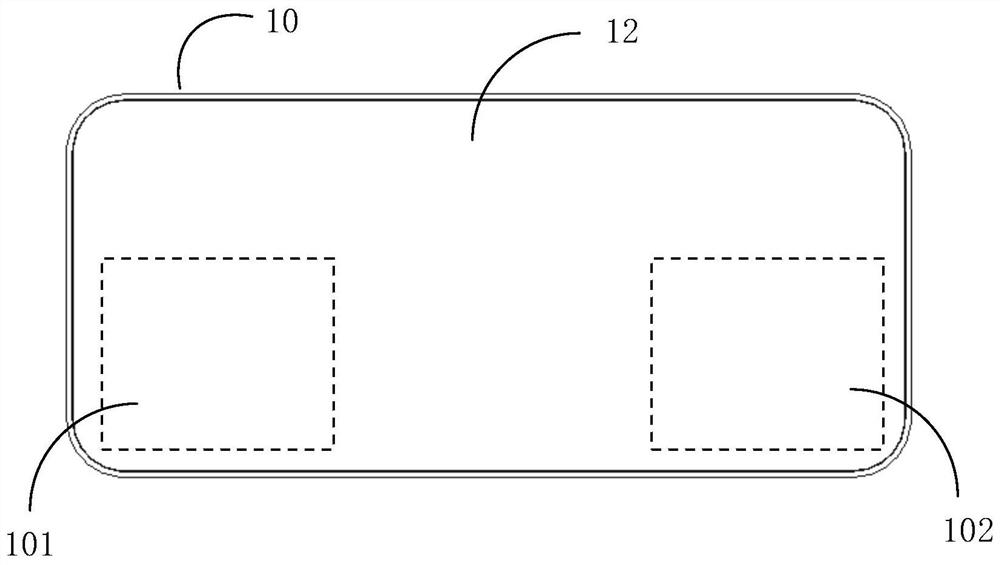

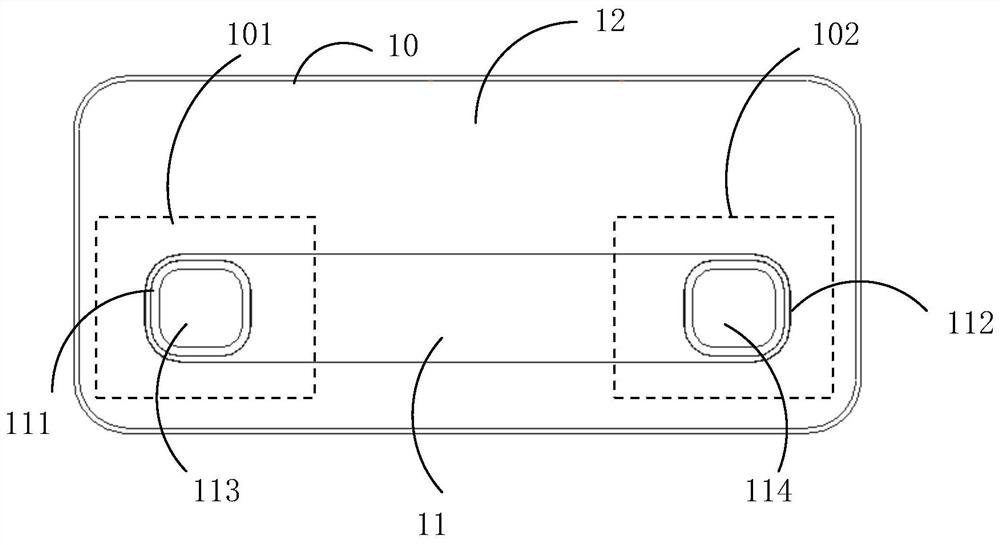

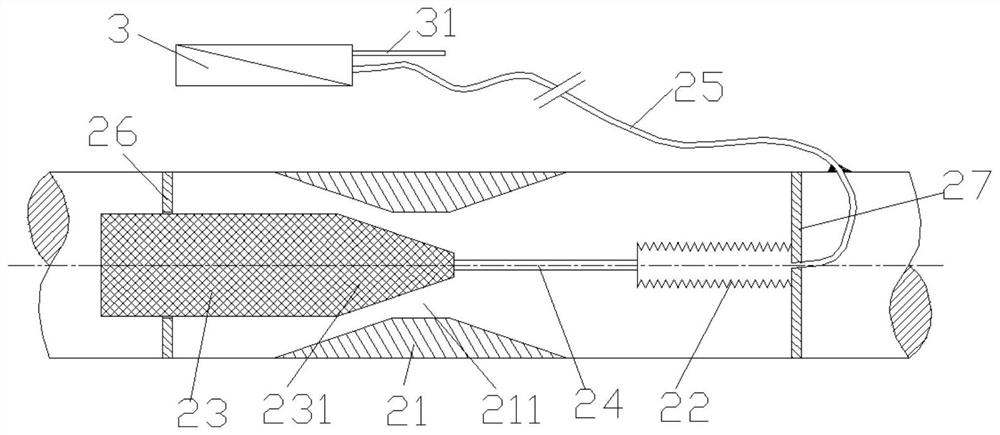

Ice cup having flashy base

InactiveCN107647736ANovel structureEasy to useDrinking vesselsAtmosphereElectrical and Electronics engineering

The technical scheme of the invention is an ice cup having a flashy base. The ice cup includes a cup body and a base connected to a lower end of the cup body; the cup body includes an inner cup wall and an outer cup wall; bottoms of the inner cup wall and the outer cup wall are in sealed connection with the base, and the inner cup wall, the outer cup wall and the base form a hollow region filled with a cooling medium; a top surface of the base and the inner cup wall form an inner wall cavity of the cup body; flashy lamps, a circuit board and a power supply are arranged in the base; a positiveelectrode conductive column and a negative electrode conductive column are arranged on the circuit board; the positive electrode conductive column and the negative electrode conductive column pass through the top surface of the base; and the height of top surfaces of the positive electrode conductive column and the negative electrode conductive column is not lower than the height of a bottom surface of the inner wall of the cup body. The ice cup is novel in structure, is safe and reliable to use, has lamp colors as needed, can enhance atmosphere, and can be used in entertainment venues such asKTV.

Owner:何慧民

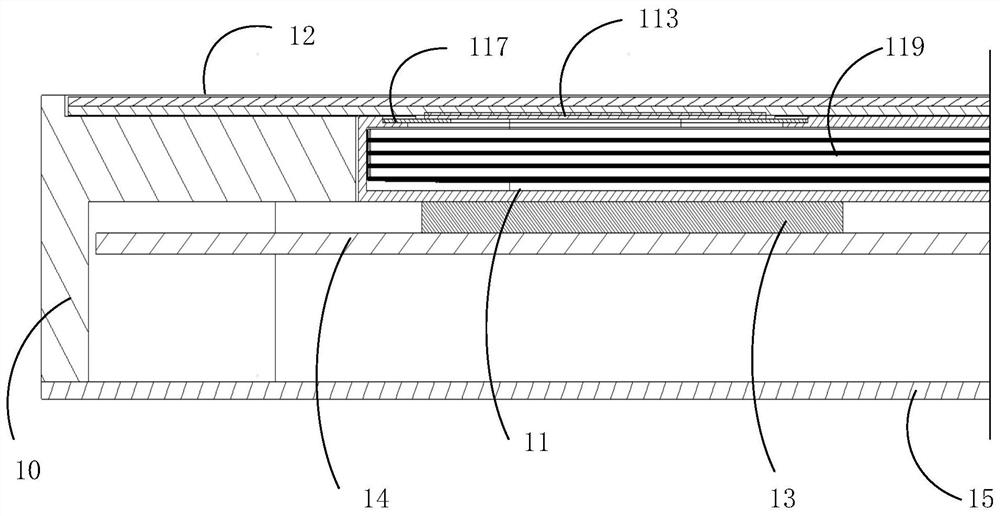

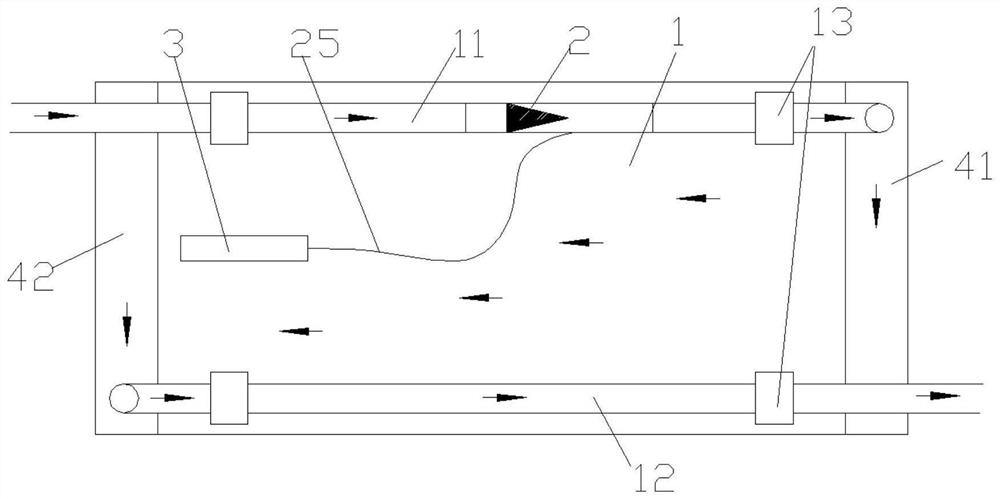

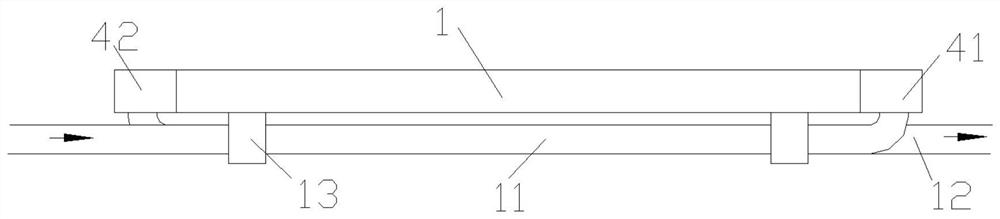

Electronic device

ActiveCN113141760AImprove cooling efficiencyImprove cooling effectModifications using liquid coolingEngineeringFlexible display

Owner:VIVO MOBILE COMM CO LTD

Heat exchange substrate assembly, heat exchange module, controller and air conditioner

PendingCN112185913AAvoid condensationThermometer detailsLighting and heating apparatusThermodynamicsEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Double-liquid quenching method for screw rod based on infrared temperature detection

InactiveCN109423547AGet temperature in real timeReduce the chance of crackingFurnace typesHeat treatment process controlRoom temperatureCooling fluid

Owner:南京雄豹精密机械有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap