Pressure vessel and vehicle

A technology for pressure vessels and bottle valves, which is applied to pressure vessels, road vehicles, vehicle parts, etc. It can solve the problems of pressure vessel A0 sealing failure and poor sealing reliability, so as to achieve reliable vehicle operation, strong sealing reliability, and reduce sealing difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] It should be noted that the features in the present invention in the present invention can be combined with each other in the case of an unable conflict.

[0027] The present invention will be described in detail below with reference to the drawings.

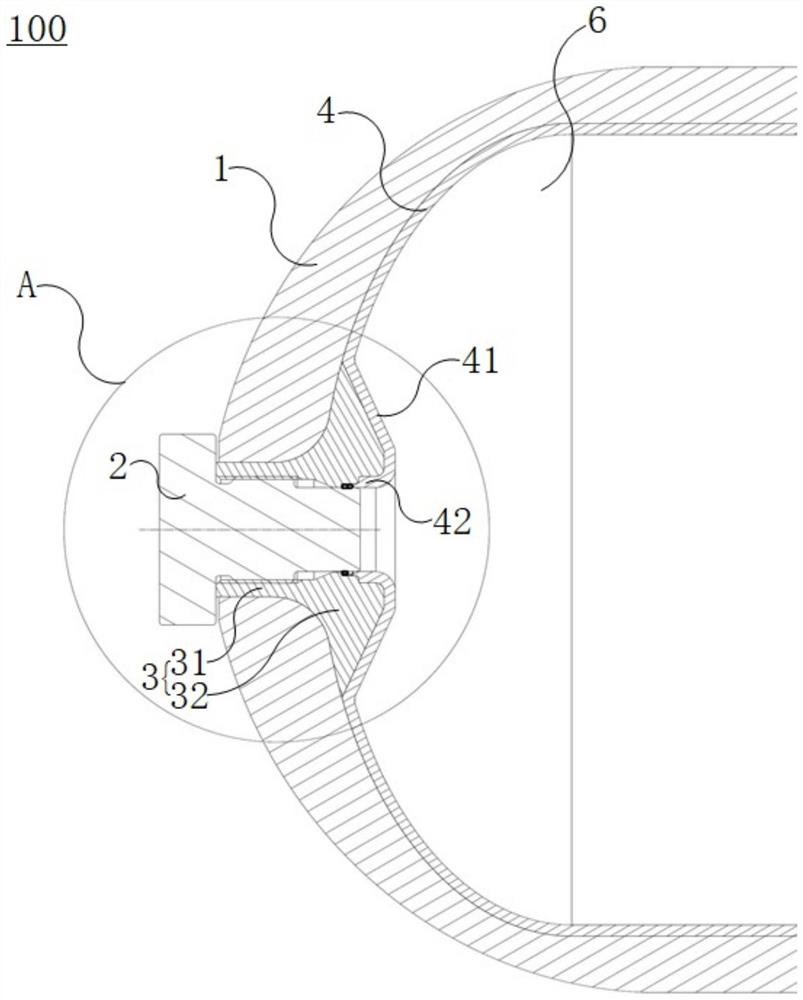

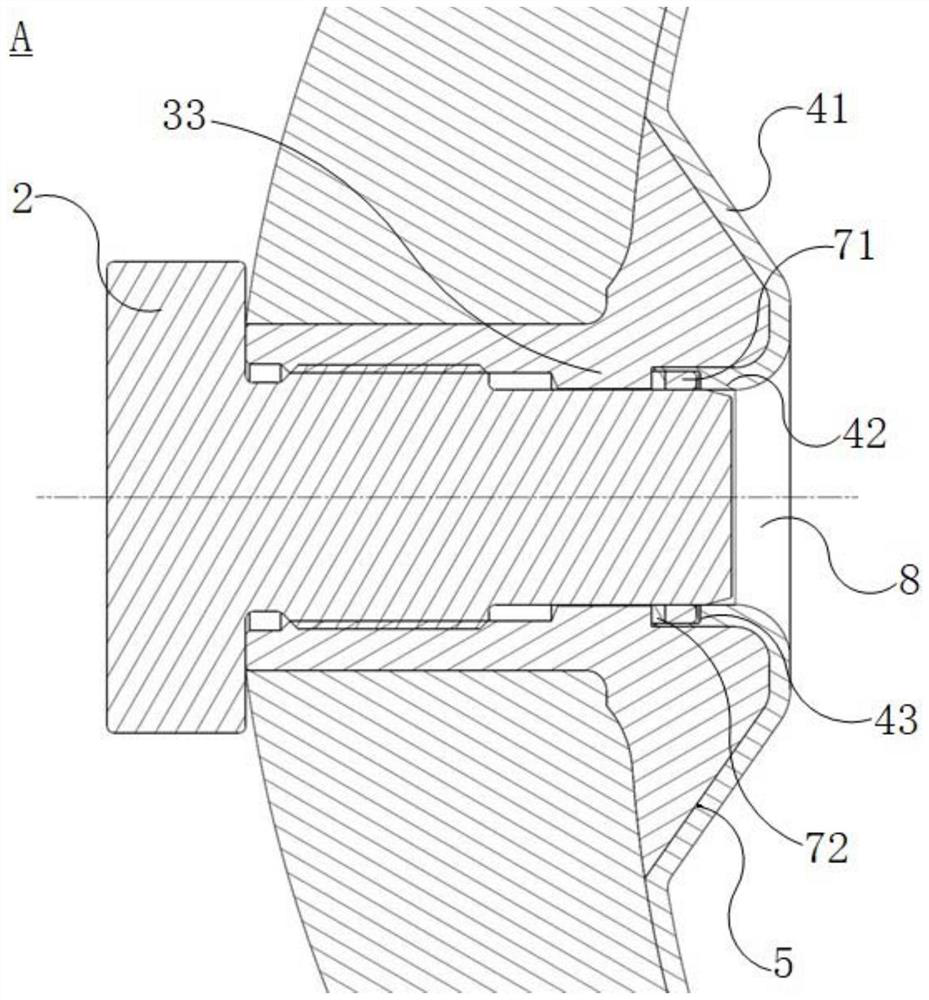

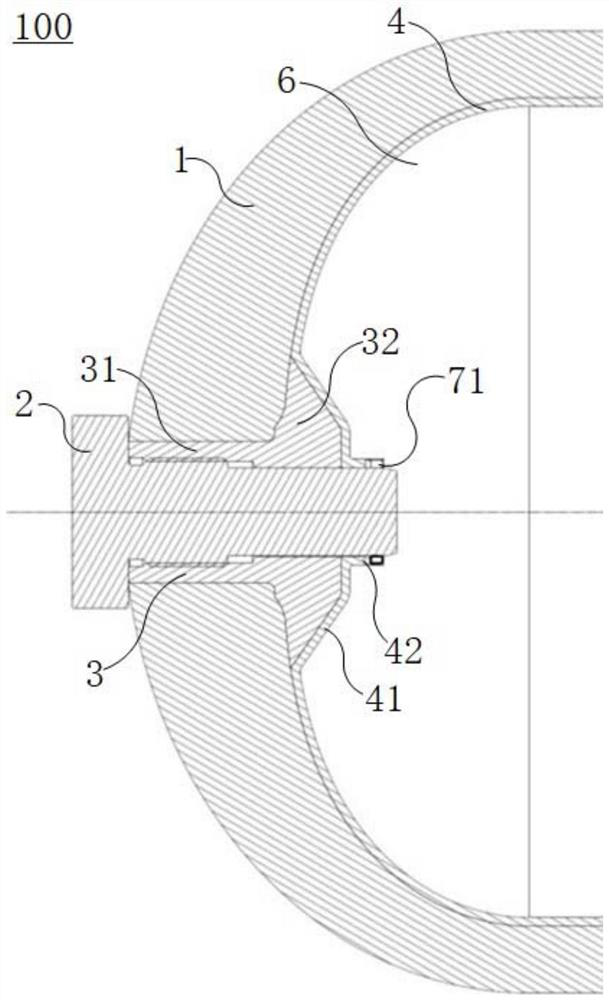

[0028] Below Figure 1 - Figure 3 The pressure vessel 100 of the embodiment of the present invention will be described with reference to the examples.

[0029] Such as Figure 1 - Figure 3 As shown, the pressure vessel 100 can include a housing 1, a bottle valve 2, a valve seat 3, a housing 4 having a storage space 6, a storage space 6 for storing a gas, a liquid, and the like. The housing 1 has a communication passage 8 that communicates with the outside, and the bottle valve 2 is provided at the communication passage 8 for adjusting the opening degree of the communication passage 8, and the bottle valve 2 is opened, and the external fluid can pass through the bottle valve 2 through communication. The passage 8 enters the press

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap