Steel bar scattering machine and steel bar feeding machine

A technology for breaking up machines and steel bars, which is applied to conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of requiring manual assistance, operation, labor and safety hazards, etc., and achieve a wide range of applications and universal use. The effect of strong performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

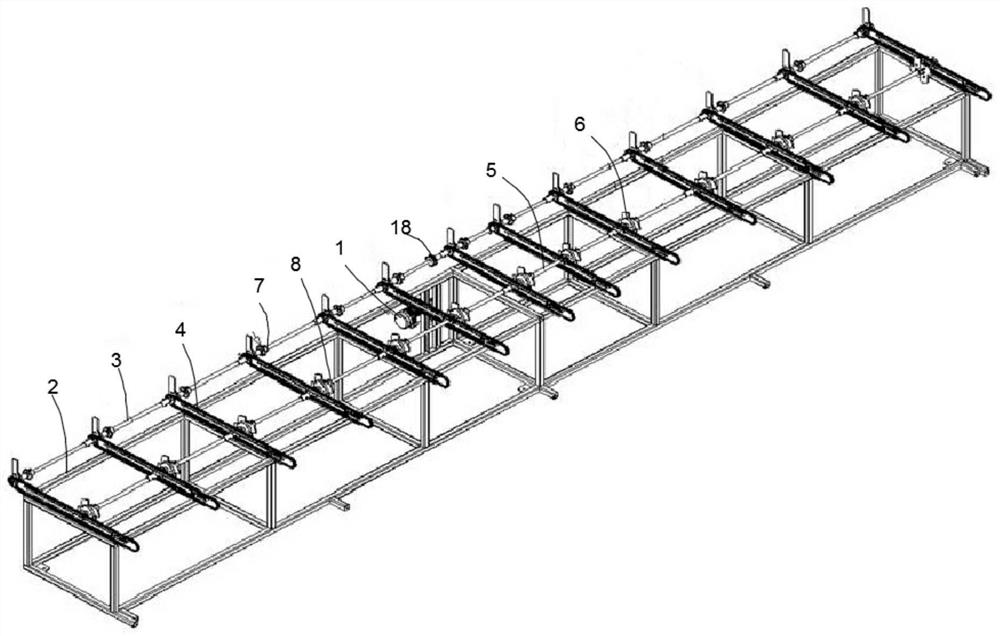

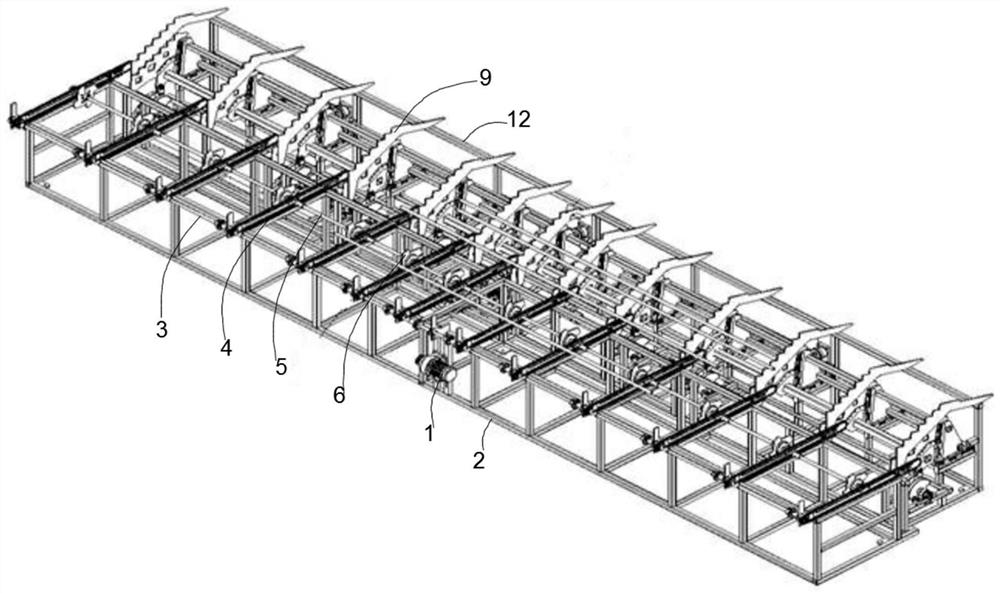

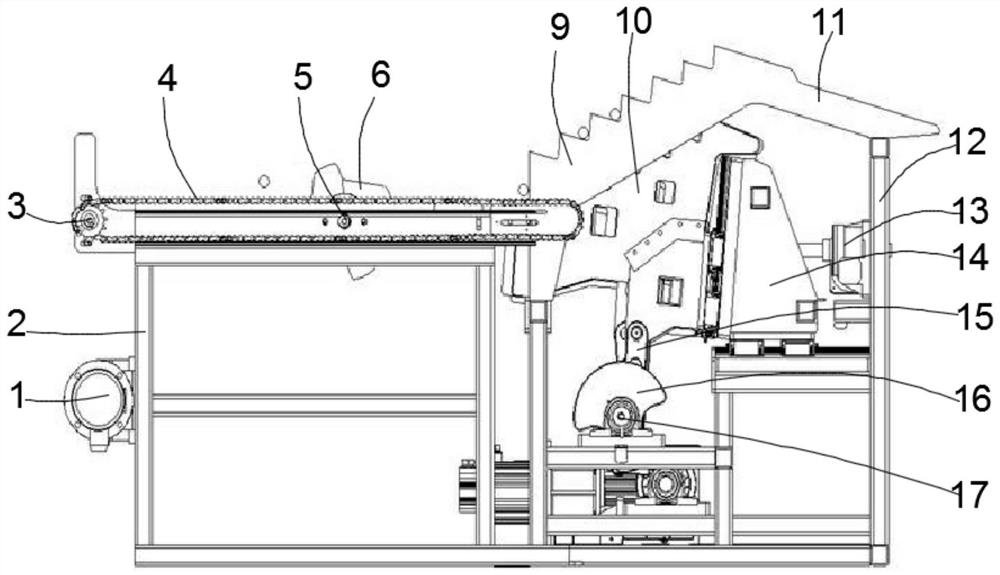

[0028] Such as Figure 1 to Figure 4 As shown, the steel bar breaking machine provided by this embodiment includes a frame 2, the top of the frame 2 is located in the same horizontal plane and is provided with multiple sets of sprocket chain transmission assemblies 4 in parallel, and the frame 2 is located on multiple sets of sprocket chains. The transmission feeding end of the transmission assembly 4 is provided with a sprocket transmission shaft 3, and the sprocket transmission shaft 3 is connected with a rotating drive mechanism; Wheel drive shaft 3 is fixedly connected with the same axis; The upper turret on the frame 2 within the transmission length range of sprocket chain drive assembly 4 is provided with a material transfer shaft 5 parallel to the sprocket drive shaft 3, and the material transfer shaft 5 is connected with Dial material driving mechanism, the material dial drive shaft 5 is coaxially fixed with a plurality of multi-tooth dial cam plates 6 .

[0029] In this

Embodiment 2

[0034] Such as figure 1 with Figure 4As shown, the steel bar feeding machine provided in this embodiment includes a steel bar breaking machine and a steel bar rubbing machine; the steel bar breaking machine includes a frame 2, and the top of the frame 2 is located in the same horizontal plane and is provided with multiple sets of sprockets in parallel Chain transmission assembly 4, the transmission feed end that is positioned at multiple groups of sprocket chain transmission assemblies 4 on frame 2 is provided with sprocket transmission shaft 3, and sprocket transmission shaft 3 is connected with rotary drive mechanism; The sprocket 7 is all sleeved on the sprocket drive shaft 3 and is coaxially fixedly connected with the sprocket drive shaft 3; Parallel material shifting transmission shaft 5 is connected with a material shifting drive mechanism, and a plurality of multi-tooth dialing cam plates 6 are coaxially fixed on the dialing transmission shaft 5 at intervals.

[0035] I

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap