Automatic arrangement die-pressing concrete die-pressing device

A technology of automatic arrangement and compression molding device, which is applied in the field of compression molding concrete, can solve the problems of large angle error, inconvenient laying, manual cleaning efficiency of mold boards, etc., and achieve the effect of preventing inaccurate fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

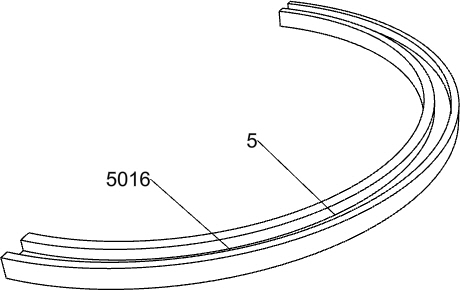

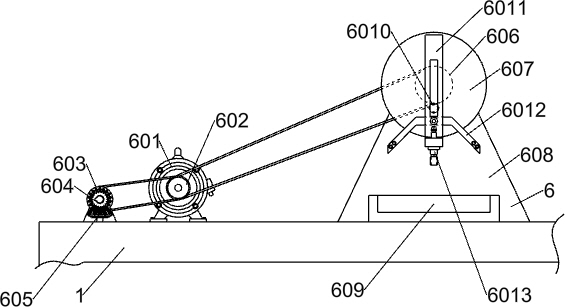

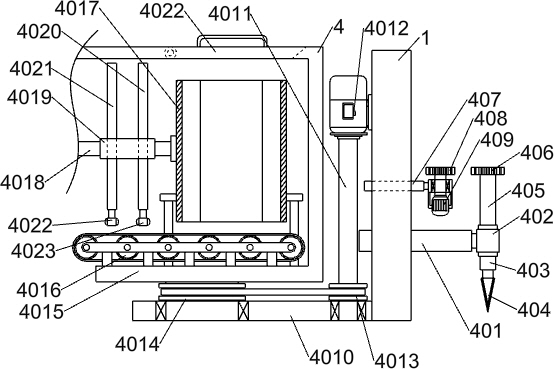

[0084] A device for automatically arranging press molded concrete press molds, such as Figure 1-7 As shown, it includes car body frame 1, electric wheel 2, battery 3, mold placement system 4, compaction system 5, cleaning system 6 and regular hexagonal mold plate 7; the upper part of electric wheel 2 is connected with car body frame 1 The bottom of the battery 3 is bolted to the car body frame 1; the mold placement system 4 is connected to the car body frame 1; the compaction system 5 is connected to the car body frame 1; the cleaning system 6 is connected to the car body frame 1, cleaning The system 6 is connected with the compacting system 5 ; the regular hexagonal mold plate 7 is connected with the mold placement system 4 .

[0085] Working steps: When using the automatic arrangement of compression molded concrete compression molding device, first connect the controller externally, then connect the battery 3 inside the device to supply power to the device, the manual control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap