Method for stably fixing first-section pipe section of super-large-diameter GRP pipeline under water

A super-large-diameter, pipeline-based technology, applied in the first section of super-large-diameter GRP pipelines to save water and stabilize and fix the field, to achieve the effects of improving construction quality, reducing construction costs, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and embodiments, but the present invention is not limited to the specific embodiments.

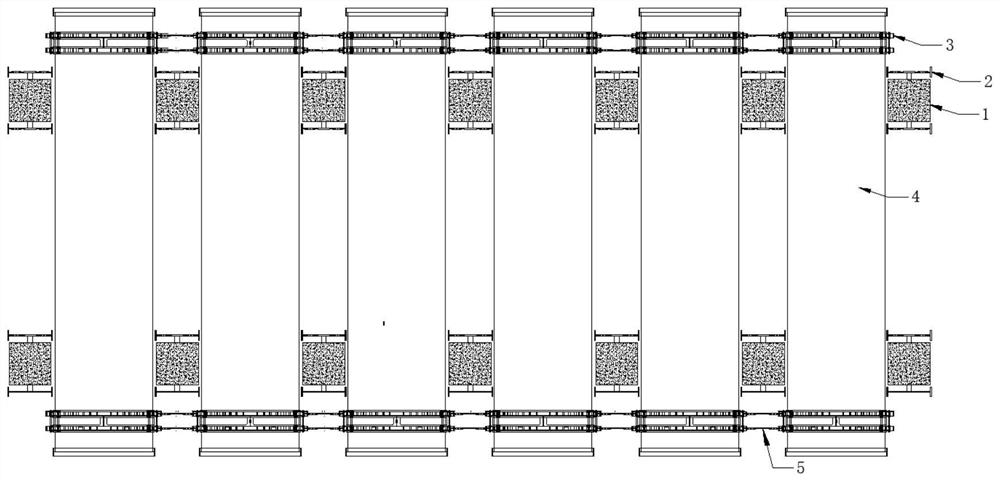

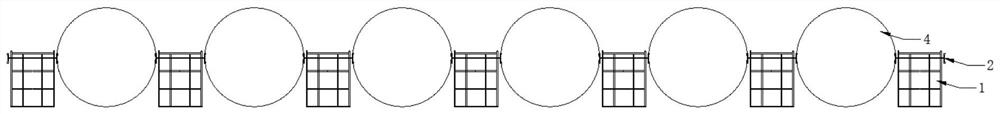

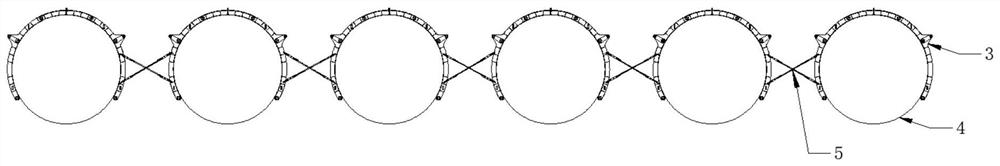

[0034] Such as Figure 1-4 As shown, a method for stably fixing the first section of a super-large-diameter GRP pipeline under water, including the following steps:

[0035] S1: Lower the first section of the first section of pipeline, lower the first section of the first section of pipeline according to the measurement and control system on the pipeline lifting tool, and adjust the position of pipeline 4 so that the error between the actual coordinates of the pipeline and the design coordinates of the pipeline shall not exceed 2cm;

[0036] S2: Lower the sandbox and fix the pipeline. After the installation of the first section of the first pipe joint is completed, lift the sandbox 1 and lower it to the position 10cm outside the two ends of the pipeline 4. The sandbox 1 is 2m long, 1.5m wide and 2.5m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap