Circuit board flat cable detection device and detection method

A detection device and circuit board technology, which is applied in the direction of measurement device, electronic circuit test, measurement device shell, etc., can solve the problems of long circuit board repair cycle, cumbersome inspection engineering, and cumbersome inspection process, so as to reduce the defect rate of products and avoid The effect of wiring confusion and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

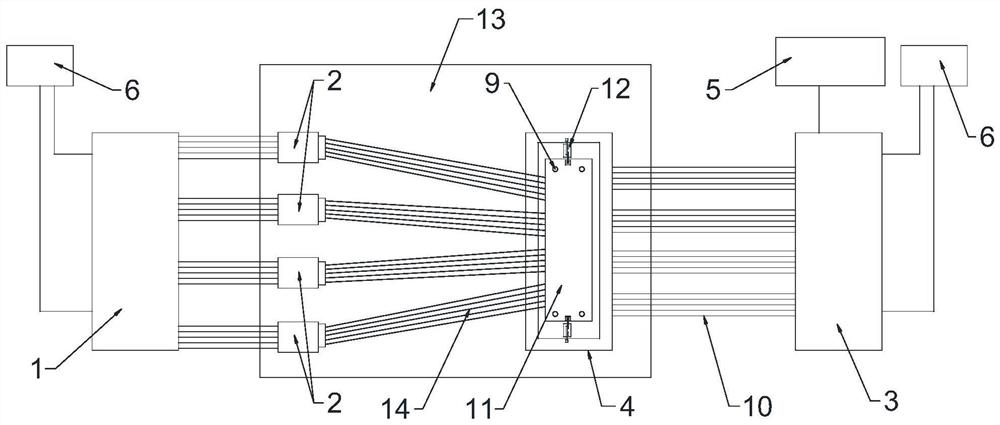

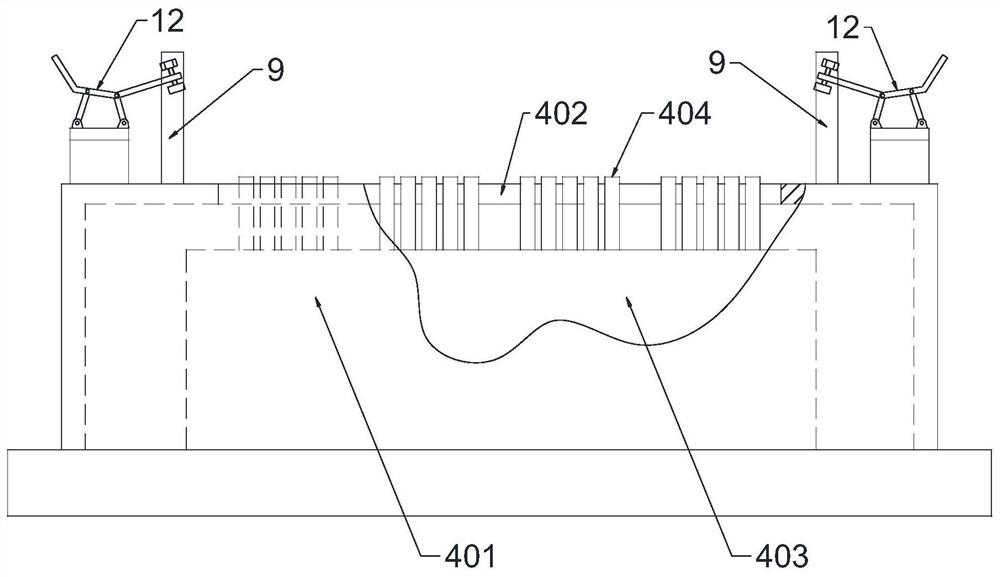

[0033] Such as Figure 1~Figure 5 As shown, the circuit board cable detection device in this embodiment includes a signal output module 1, an output terminal 2 electrically connected to the signal output module 1, a signal receiving and comparing module 3, and a detection device electrically connected to the signal receiving and comparing module 3. Seat 4, the detection result output module 5 electrically connected with the signal receiving comparison module 3 and the power supply 6 supporting the operation of the device, the detection seat 4 includes a rectangular shell 401, the upper end of the shell 401 is provided with a detection port 402, and the inside of the shell 401 is provided with An insulating base 403, a plurality of probes 404 corresponding to the cable connection points 8 on the circuit board 7 are inserted vertically on the base

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap