Dried fruit preparing and dicing device for food processing

A food processing and dicing technology, applied in metal processing, food processing, application, etc., can solve the problems of low work efficiency and complex production process, and achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

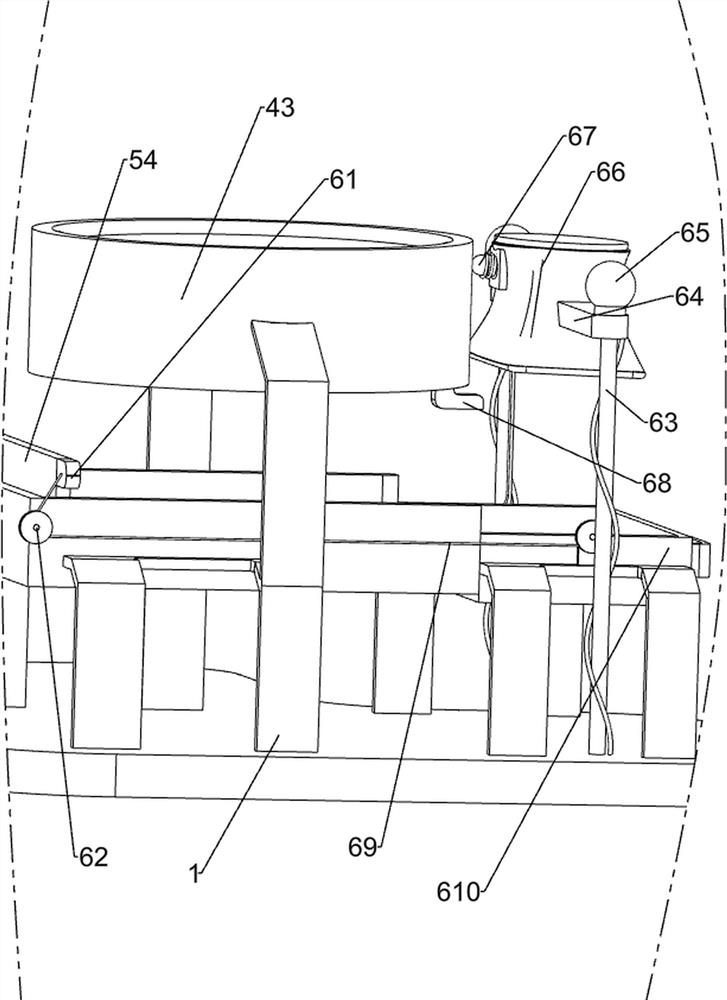

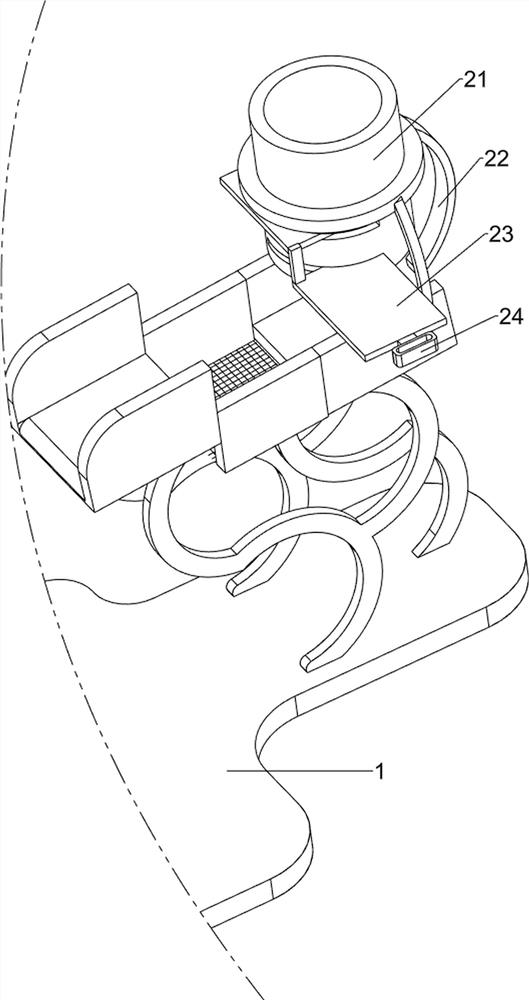

[0066] A device for preparing and dicing dried fruit for food processing, such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a base 1, a material control mechanism 2, a material feeding mechanism 3 and a cutting mechanism 4. The right side of the base 1 is provided with a material control mechanism 2, and the base 1 is provided with a material feeding mechanism 3. The mechanism 3 cooperates with the material control mechanism 2, and the left side of the base 1 is provided with a cutting mechanism 4.

[0067] When people use the present invention, first put the cleaned fruit in the material control mechanism 2, then drive the material control mechanism 2 to move the fruit on the base 1, and the material control mechanism 2 drives the feeding mechanism 3 to move, and the feeding The mechanism 3 sends the fruit on the base 1 to the cutting mechanism 4, and then starts the cutting mechanism 4 to cut the fruit into pieces, then closes the cutt

Embodiment 2

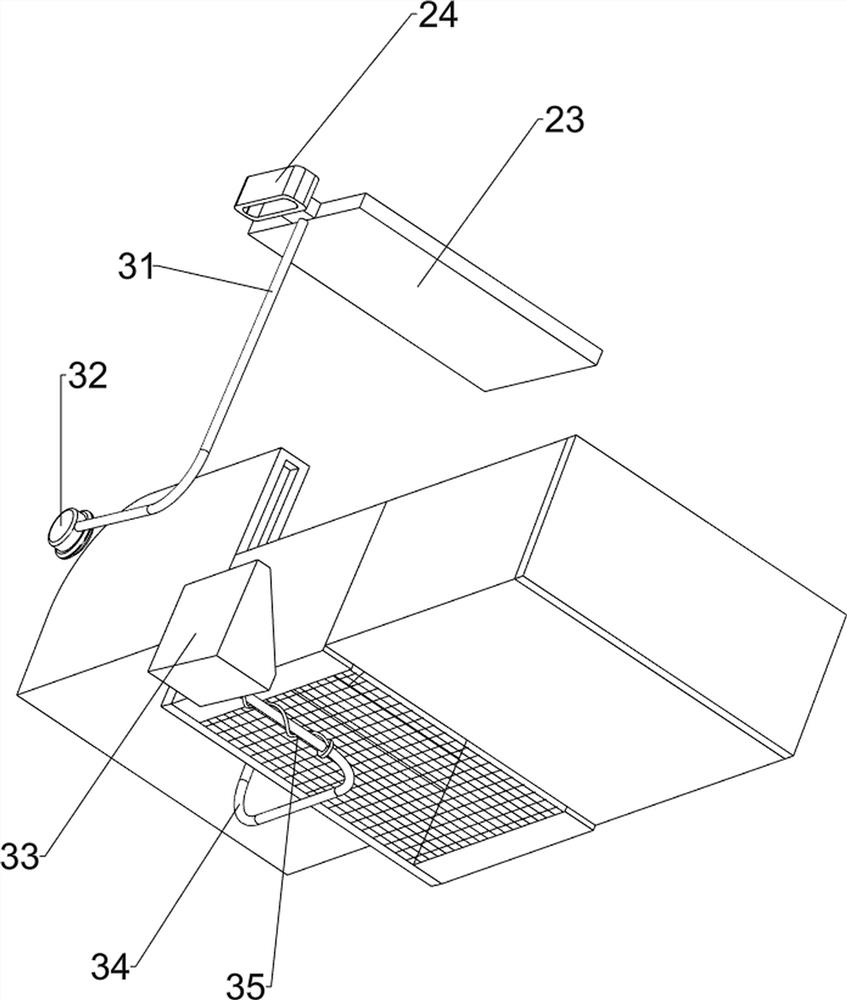

[0069] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the material control mechanism 2 includes a first material holding box 21, a first support frame 22, a material control assembly 23 and a handle 24, the right side of the base 1 is provided with a first support frame 22, and the first support frame 22 top A first material holding box 21 is provided, and a material control assembly 23 is slidably provided on the first material storage box 21 , and a handle 24 is provided on the front side of the material control assembly 23 .

[0070] First put the cleaned fruit in the first material storage box 21, then manually drive the handle 24 to move backward, the handle 24 drives the material control assembly 23 to move backward, and the fruit falls from the first material storage box 21 onto the base 1 , the material control assembly 23 drives the feeding mechanism 3 to move, the feeding mechanism 3 sends the fruit

Embodiment 3

[0076] On the basis of Example 2, such as figure 1 , Figure 5 , Figure 6 and Figure 7 Shown, also comprise pusher mechanism 5, be provided with pusher mechanism 5 on the material receiving funnel 45, pusher mechanism 5 includes support seat 51, push rod 52, spring 53 and push plate 54, the rear side of material receiving funnel 45 The middle part is provided with a support seat 51, and a push rod 52 is slidably arranged on the support seat 51, and a spring 53 is wound on the push rod 52, and the spring 53 is connected with the support seat 51 and the push rod 52, and a push plate 54 is provided on the front side of the push rod 52 .

[0077] After the fruit is cut into pieces, it falls onto the receiving funnel 45, a receiving box is placed in front of the receiving funnel 45, and then the push rod 52 is manually driven to move forward, the spring 53 becomes compressed, and the push rod 52 drives the push plate 54 Move forward to push the fruit block into the material rece

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap