Silicone rubber mold

A silicone rubber and mold technology, applied in the direction of coating, etc., can solve the problems of long product cooling time, slow processing efficiency, low product quality, etc., and achieve the effects of ensuring sealing performance, improving processing quality, and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

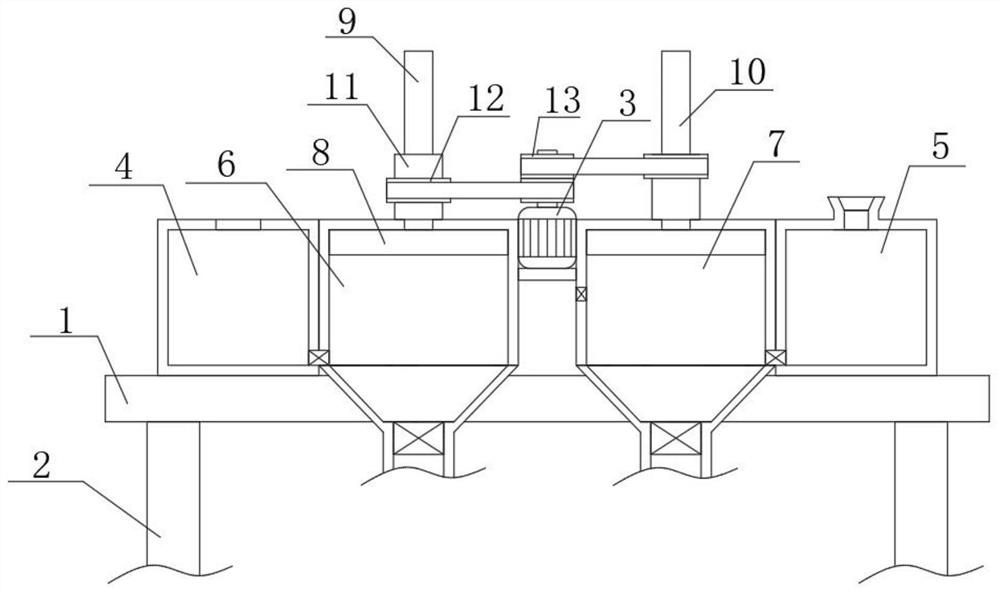

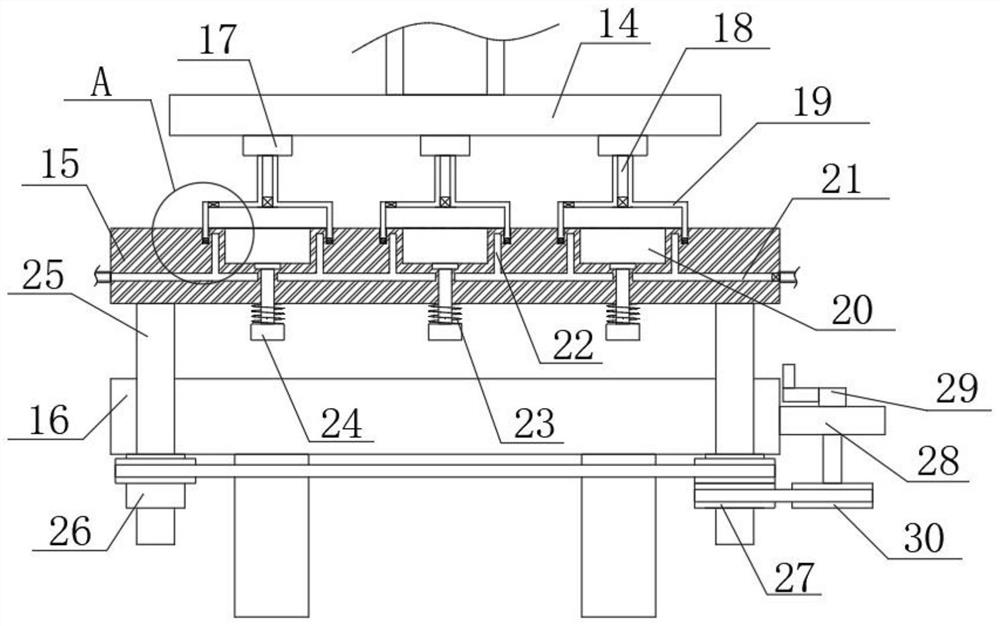

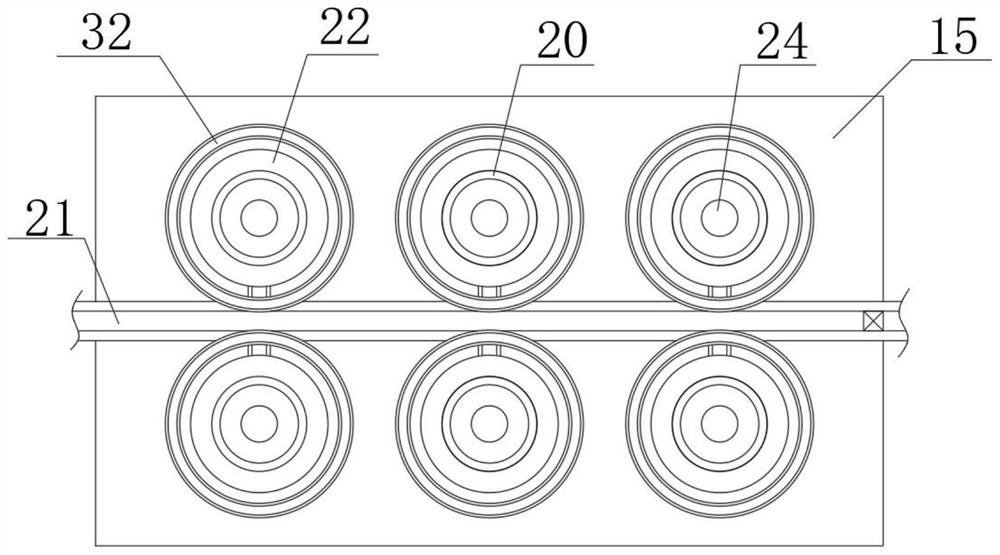

[0025] Refer Figure 1-4 A silicone rubber mold comprising a support plate 1 plurality of support frame 2, and the support plate 1 is fixedly coupled to the plurality of support frames 2, and the support plate 1 is fixed from the side wall of the support frame 2 to secure the water cooling device 4, the storage tank. 5, the water supply device 6 and the feed device 7, the water supply device 6 and the feed device 7 are provided with a piston plate 8, and the plurality of piston plate 8 side walls are fixedly connected to the first threaded rod 9 and the second threaded rod 10, first The threaded rod 9 and the second threaded rod 10 are all rotated by a threaded rotation with a first thr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap