Method for producing isopropanolamine and 1, 2-propane diamine by cracking 2, 6-dimethyl piperazine

A technology of dimethylpiperazine and isopropanolamine, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve problems such as inability to use, and achieve easy parameter control, easy industrialization promotion, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

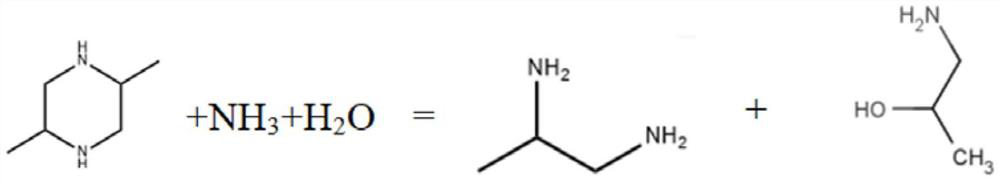

Image

Examples

Embodiment 1

[0043] The method for producing isopropanolamine and 1,2-propylenediamine by cracking 2,6-dimethylpiperazine described in Example 1 consists of the following steps:

[0044] (1) Pass 2,6-dimethylpiperazine into the vaporizer of the reaction system, heat and vaporize the mixed gas of ammonia and water, and then mix with Co-Mo-Pd / Al in the reactor 2 o 3 The catalyst carries out the contact cracking reaction;

[0045] (2) After condensing the reaction product obtained in step (1), enter the distillation separation system to obtain pure isopropanolamine and 1,2-propanediamine.

[0046] in:

[0047] The Co-Mo-Pd / Al 2 o 3 For the catalyst, based on the weight of the metal oxide, CoO is 2% of the weight of the catalyst, MoO is 2% of the weight of the catalyst, and PdO is 2% of the weight of the catalyst.

[0048]The Co-Mo-Pd / Al 2 o 3 The catalyst has a pore volume of 0.5ml / g and a specific surface area of 280m 2 / g.

[0049] The temperature of the mixed gas of ammon

Embodiment 2

[0071] The method for producing isopropanolamine and 1,2-propylenediamine by cracking 2,6-dimethylpiperazine described in Example 2 consists of the following steps:

[0072] (1) Pass 2,6-dimethylpiperazine into the vaporizer of the reaction system, heat and vaporize the mixed gas of ammonia and water, and then mix with Co-Mo-Pd / Al in the reactor 2 o 3 The catalyst carries out the contact cracking reaction;

[0073] (2) After condensing the reaction product obtained in step (1), enter the distillation separation system to obtain pure isopropanolamine and 1,2-propanediamine.

[0074] in:

[0075] The Co-Mo-Pd / Al 2 o 3 For the catalyst, based on the weight of the metal oxide, CoO is 3% of the weight of the catalyst, MoO is 2% of the weight of the catalyst, and PdO is 3% of the weight of the catalyst.

[0076] The Co-Mo-Pd / Al 2 o 3 The catalyst has a pore volume of 0.8ml / g and a specific surface area of 350m 2 / g.

[0077] The temperature of the mixed gas of ammo

Embodiment 3

[0099] The method for producing isopropanolamine and 1,2-propylenediamine by cracking 2,6-dimethylpiperazine described in Example 3 consists of the following steps:

[0100] (1) Pass 2,6-dimethylpiperazine into the vaporizer of the reaction system, heat and vaporize the mixed gas of ammonia and water, and then mix with Co-Mo-Pd / Al in the reactor 2 o 3 The catalyst carries out the contact cracking reaction;

[0101] (2) After condensing the reaction product obtained in step (1), enter the distillation separation system to obtain pure isopropanolamine and 1,2-propanediamine.

[0102] in:

[0103] The Co-Mo-Pd / Al 2 o 3 As for the catalyst, based on the weight of the metal oxide, CoO is 3% of the weight of the catalyst, MoO is 1% of the weight of the catalyst, and PdO is 4% of the weight of the catalyst.

[0104] The Co-Mo-Pd / Al 2 o 3 The catalyst has a pore volume of 0.3ml / g and a specific surface area of 200m 2 / g.

[0105] The temperature of the mixed gas of a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap