Inventory management method based on raw material warehouse scale

A technology of inventory management and raw material warehouse, applied in data processing applications, instruments, logistics, etc., can solve the problems of reduced inventory control, lagging inventory management, large inventory fluctuations, etc., to avoid human error in materials, timely and stable transportation, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The technical solutions in the embodiments in the embodiments will be described in detail below with reference to the accompanying drawings in the embodiment of the present invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

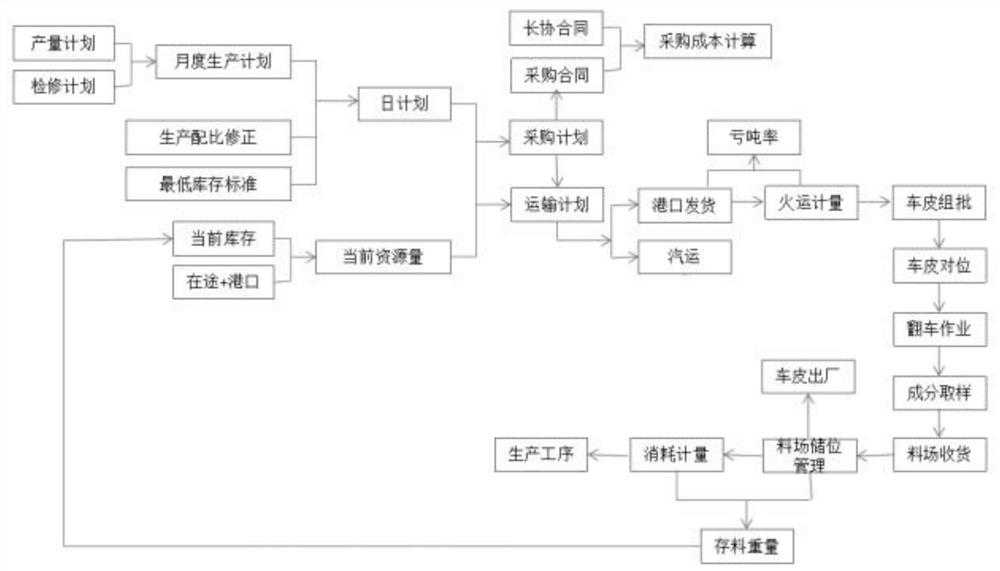

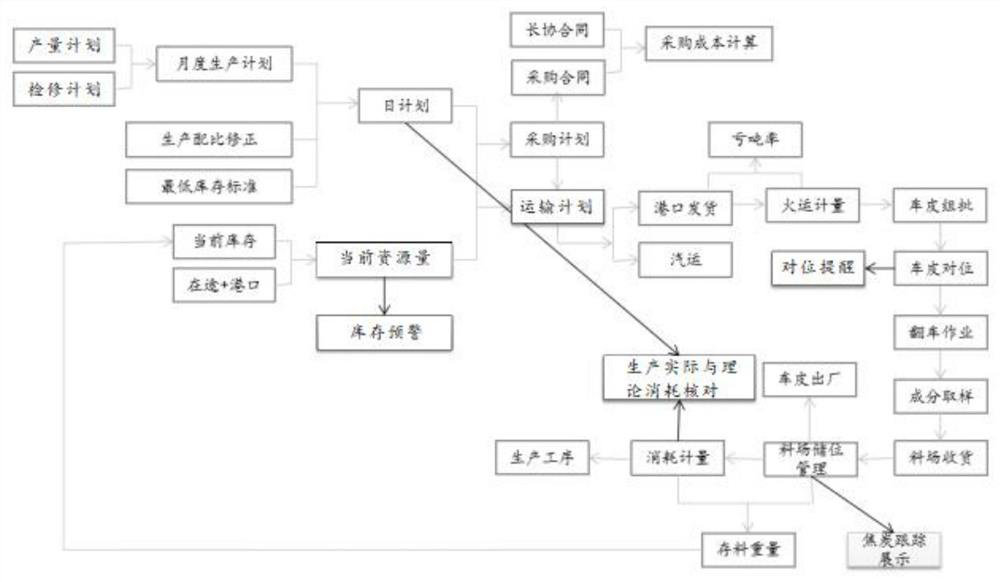

[0024] Such as Figure 1-2 As shown, an inventory management method based on raw material library, including the following steps:

[0025] 1, combing the current raw material inventory, procurement, consumption and other processes, flow charts figure 1 As shown, according to figure 1 Knowing: With the inventory as a rush to achieve the effective management of inventory, the downstream to achieve the principle of preparation according to the ratio, through the production plan, the ratio plan and inventory standard, the compaction plan and actual consumption compaction, realization The amount of the charge and belt weighing; upstream to a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap