Laser Holing device and two-step holing method

A laser drilling and laser technology, which is applied in the direction of laser welding equipment, electrical components, welding/welding/cutting items, etc., can solve the problems of adverse effects of large-scale industrial use, slow drilling speed, good hole quality, etc., to achieve It is beneficial to industrial application, improving quality and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

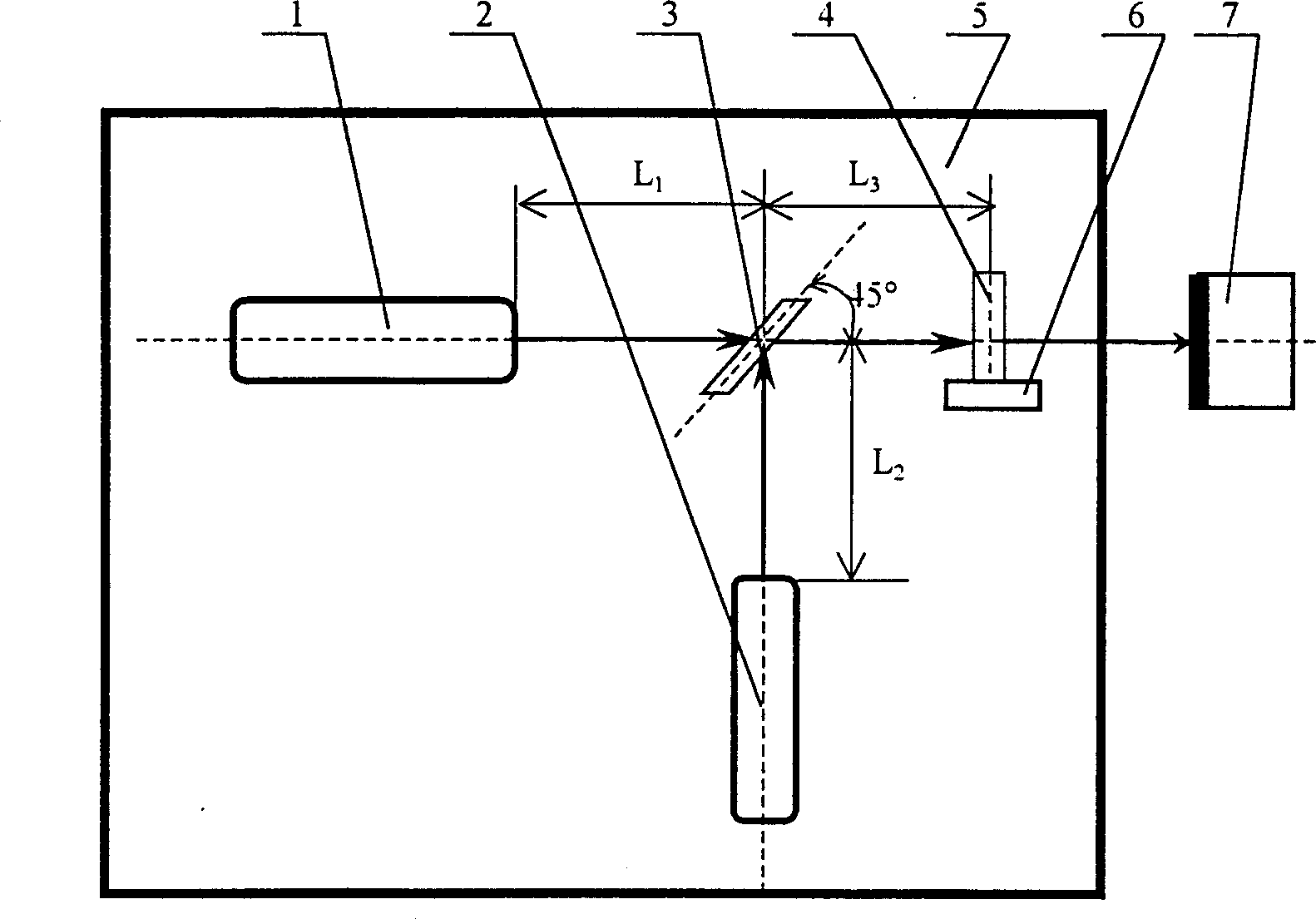

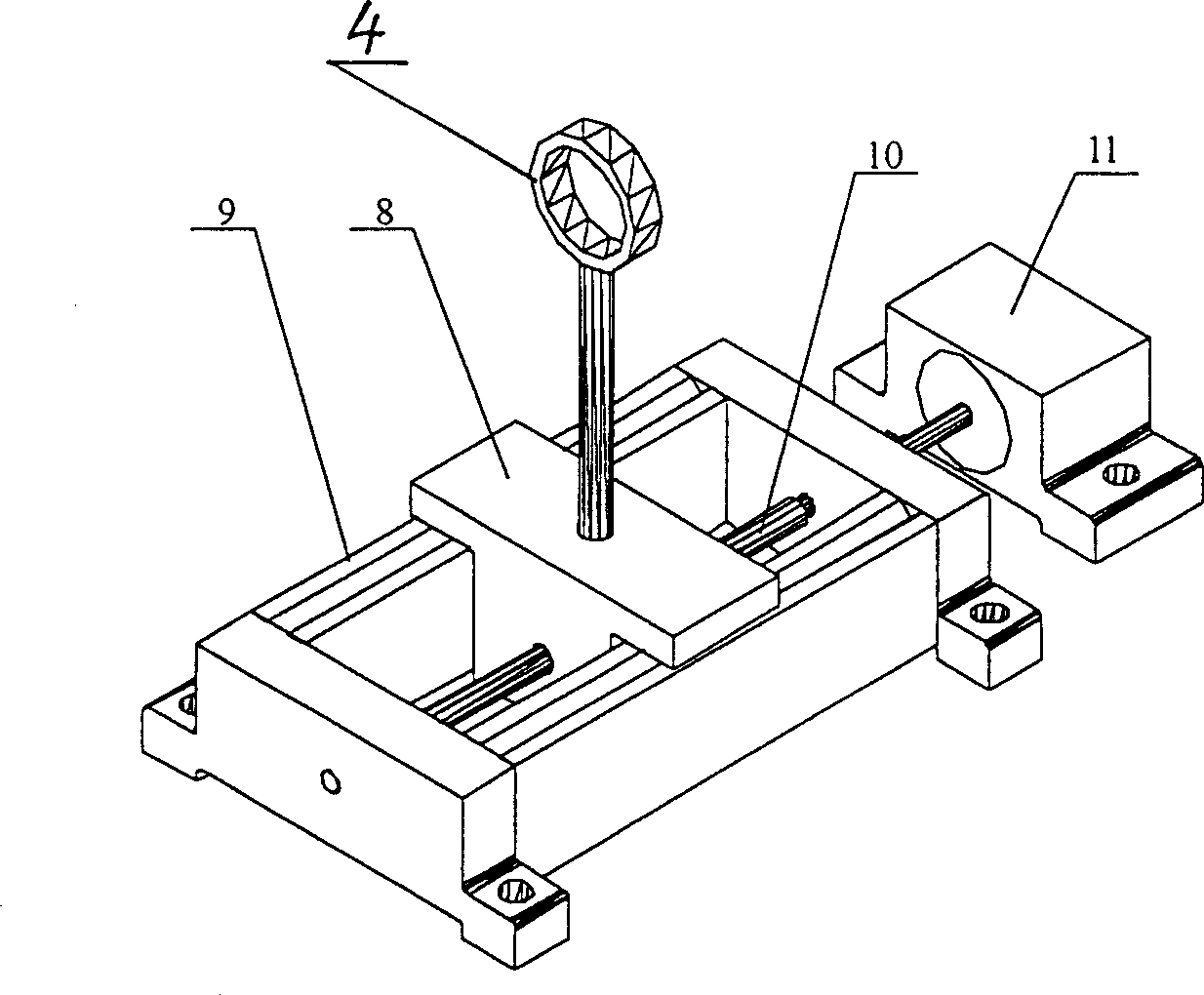

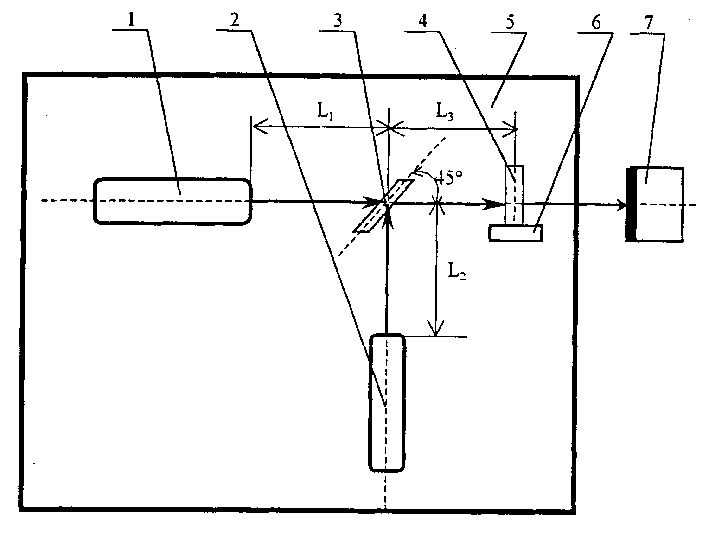

[0012] figure 1 Among them, 1 is the long-wavelength laser S 1 . 2 is short-wavelength laser S 2 . 3 is transmission / reflection plane mirror M 1 , It is able to completely transmit S 1 The output laser can be completely reflected S 2 The transmission / reflection optical plane mirror of the output laser light. 4 is focusing convex lens M 2 . 5 is the bottom plate. S 1 , S 2 , M 1 , M 2 All are installed on this bottom plate. Long Wavelength Laser S 1 With short-wavelength laser S 2 The output laser axis is on the same horizontal plane and perpendicular to each other, the transmission / reflection optical plane mirror M 1 Place the intersection with the axes of the two laser beams, and make an angle of 45° with the two axes respectively, and the two laser beams are located on both sides of the plane mirror respectively. 6 is to place the focusing convex lens M 2 的rail mechanism. 7 is the workpiece to be processed, and the laser axis output by the focusing convex lens is perpendicu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap