Soft capsule for supplementing vitamin E and production process of soft capsule

A technology for supplementing vitamins and production technology, which is applied in the field of vitamin E ingredients and production, can solve the problems of vitamin E rubber shell rupture, low vitamin E absorption rate, stomach discomfort, etc., and achieve the goal of improving absorption rate, increasing content, and preventing rupture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

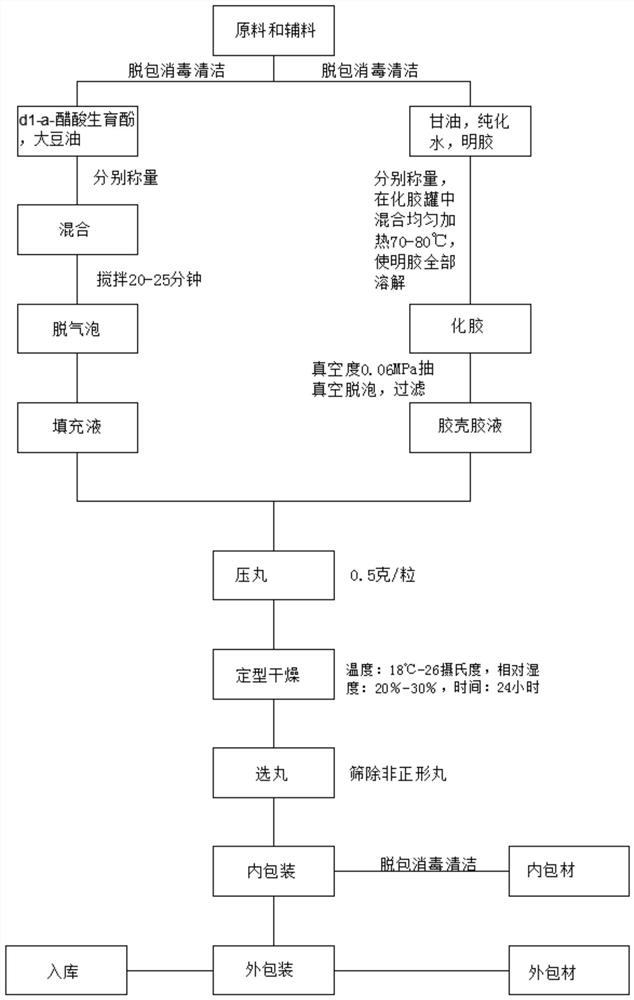

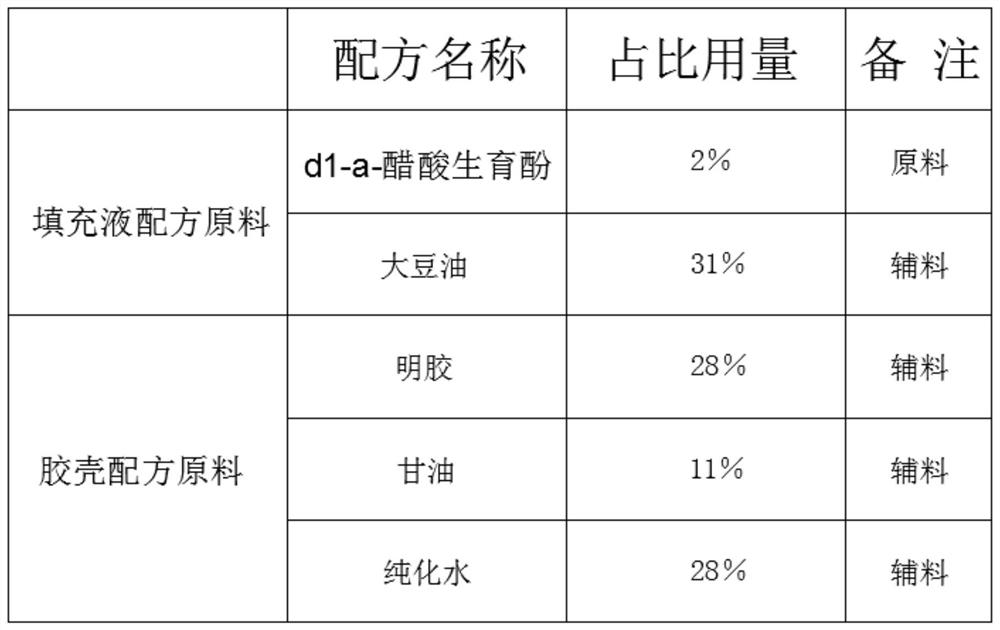

[0027] see Figure 1-2 , the present invention provides the following technical solutions: a soft capsule for vitamin E supplementation and its production process, characterized in that it includes capsule raw materials, auxiliary materials and component dosage: the raw material is d1-a-tocopheryl acetate, and the The auxiliary materials are soybean oil, gelatin, glycerin and purified water respectively, the amount of d1-a-tocopherol acetate accounts for 2%, the amount of soybean oil accounts for 31%, and the amount of gelatin accounts for 28%. The proportion of the glycerin consumption is 11%, the proportion of the purified water consumption is 28%, and each capsule has a specification of 0.5 grams. The capsule production process includes:

[0028] S1: said d1-a-tocopheryl acetate and soybean oil are mixed and stirred for 20-25 minutes after being weighed respectively according to production capacity;

[0029] S2: performing defoaming treatment on the mixed and stirred liquid o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap