River channel slope protection surface lining cast-in-place concrete expansion joint structure and construction method thereof

A construction method and technology of expansion joints, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of panel pollution forming effect, sealant coating is not full, construction is cumbersome, etc., to achieve anti-seepage and good drainage performance, Simple process, high quality and high aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

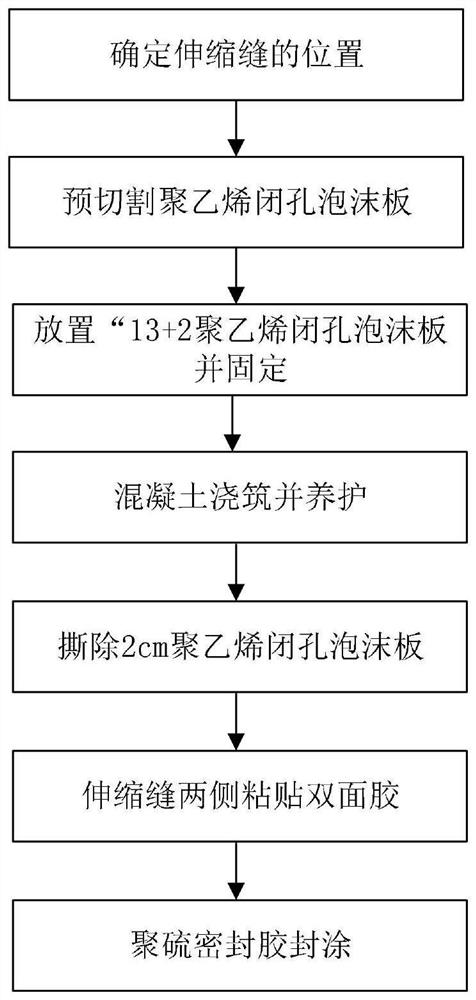

[0040] A cast-in-situ concrete joint structure and a construction method for lining a river slope protection surface, comprising the following steps:

[0041] S1 determines the position of the expansion joint 7;

[0042] S2 pre-cut polyethylene closed-cell foam board 2;

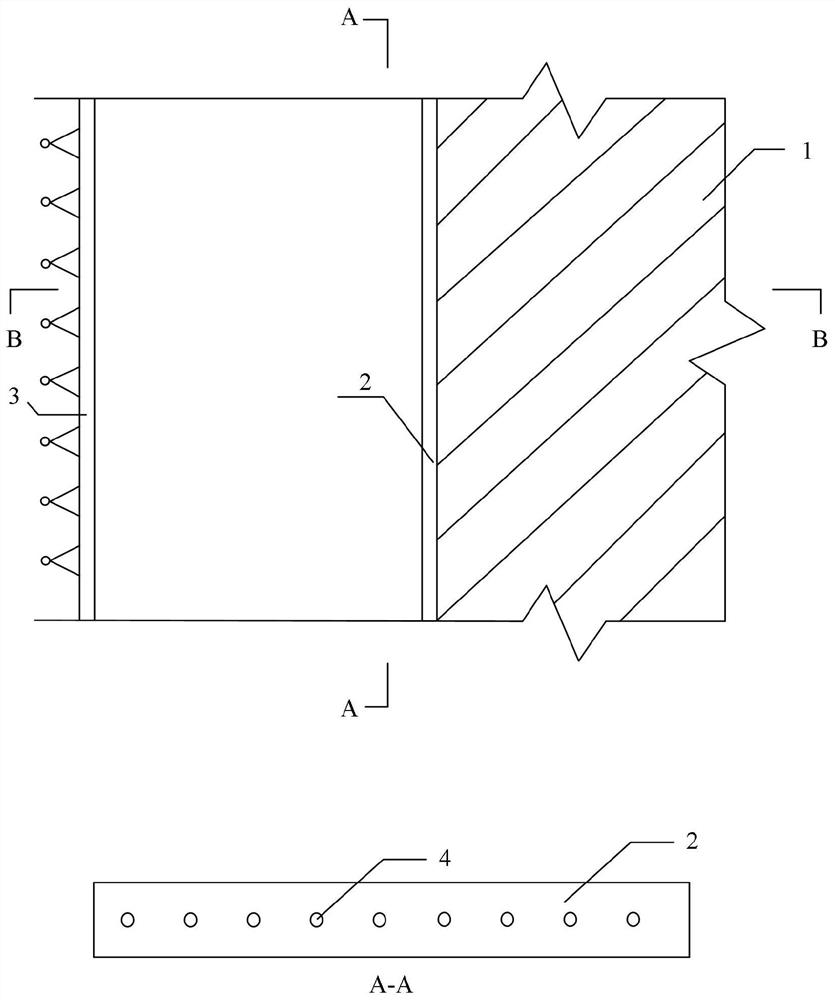

[0043] S3 places "13+2" polyethylene closed-cell foam board 2 and fixes it with iron nails 4;

[0044] Lay polyethylene closed-cell foam board 2 on the inner wall of the pouring box, and fix it with iron nails 4 after placement;

[0045] S4 Concrete layer 1 is poured and maintained;

[0046] Concrete layer 1 is poured in the installed pouring box, and the thickness of concrete layer 1 is 550mm;

[0047] S5 tear off the excess 2cm polyethylene closed-cell foam board 2;

[0048] S6 Paste double-sided adhesive tape 8 on both sides of the expansion joint 7;

[0049] S7 polysulfide sealant sealing coating;

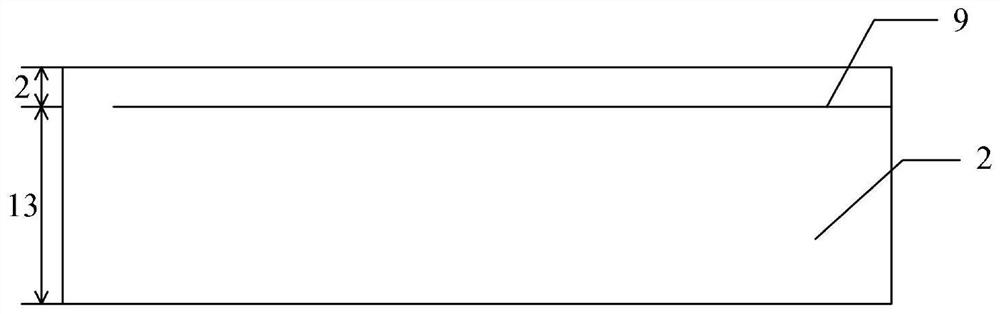

[0050] Specifically, "13+2" in step S2 is to pre-cut the 15 cm polyethylene closed-cell foam board 2 int

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap