Electromagnetic actuator with redundant air gaps

An electromagnetic actuator and air gap technology, which is applied in the aerospace field, can solve the problems of large volume and mass of the actuator, and achieve the effects of easy installation and carrying application in aerospace, small size, and alleviating magnetic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

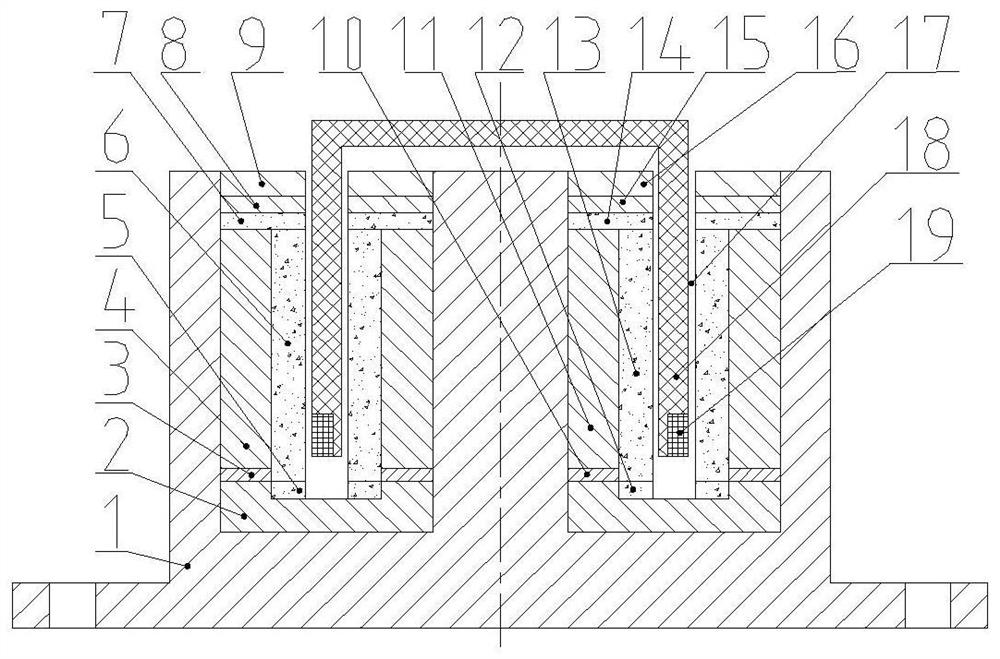

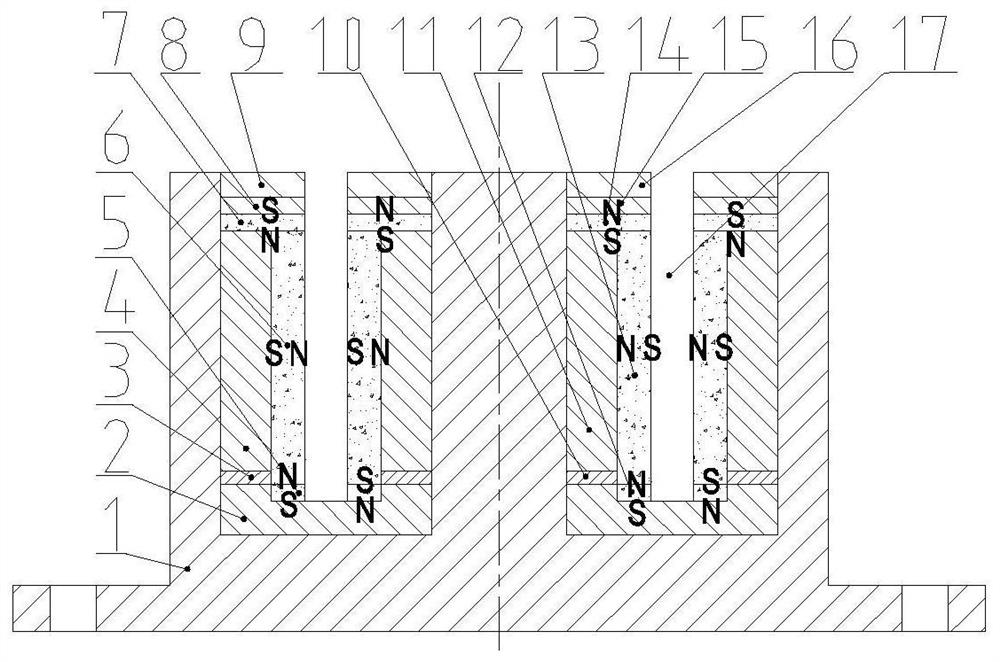

[0029] Specific implementation mode one: see Figure 1-5 This embodiment will be described.

[0030] figure 1 The radial cross-sectional view of the electromagnetic actuator that is the technical solution of the present invention is mainly composed of a stator and a mover. It is characterized in that the stator mainly includes: a stator frame 1, an end yoke 2, an outer magnetic ring 3, an outer magnetic Yoke 4, outer lower magnetic ring 5, outer magnetic ring 6, outer upper magnetic ring 7, outer upper magnetic yoke 8, outer lock nut 9, inner spacer magnetic ring 10, inner magnetic yoke 11, inner lower magnetic ring 12, inner magnetic Ring 13, inner upper magnetic ring 14, inner upper magnetic yoke 15, inner lock nut 16 and main air gap 17; the mover mainly includes: coil bobbin 18 and ring coil 19; the end yoke 2 is located at the bottom of the annular groove of stator frame 1 , the outer magnetic ring 3 is located at the axial upper end of the outer ring protrusion of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap