Electrostatic spinning nozzle structure based on capillary principle and application method thereof

An electrospinning and capillary technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of increasing the diffusion surface of spinning solution, achieve novel structure, improve yield and quality, increase The effect of a large diffusion surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

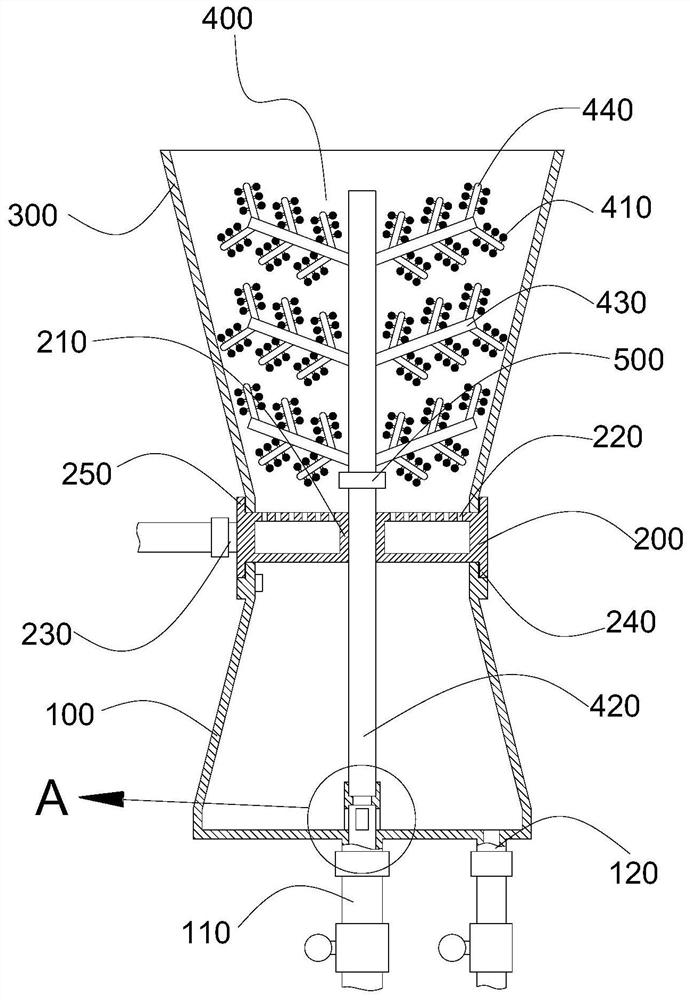

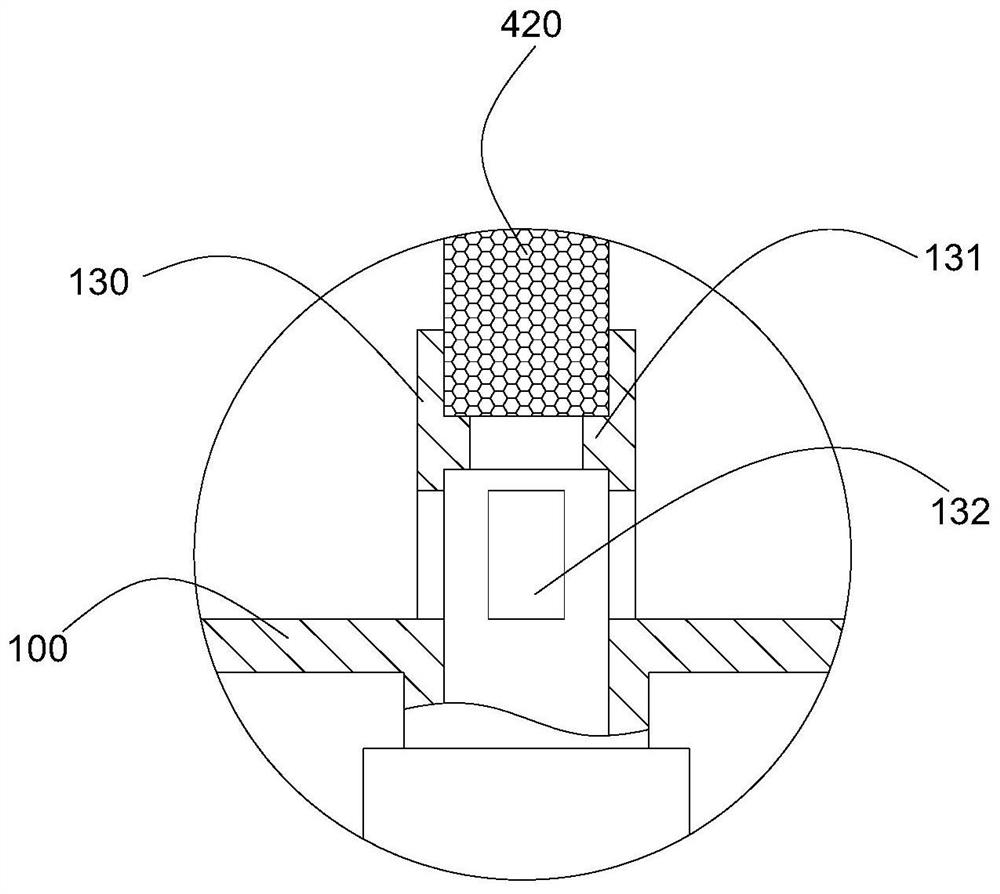

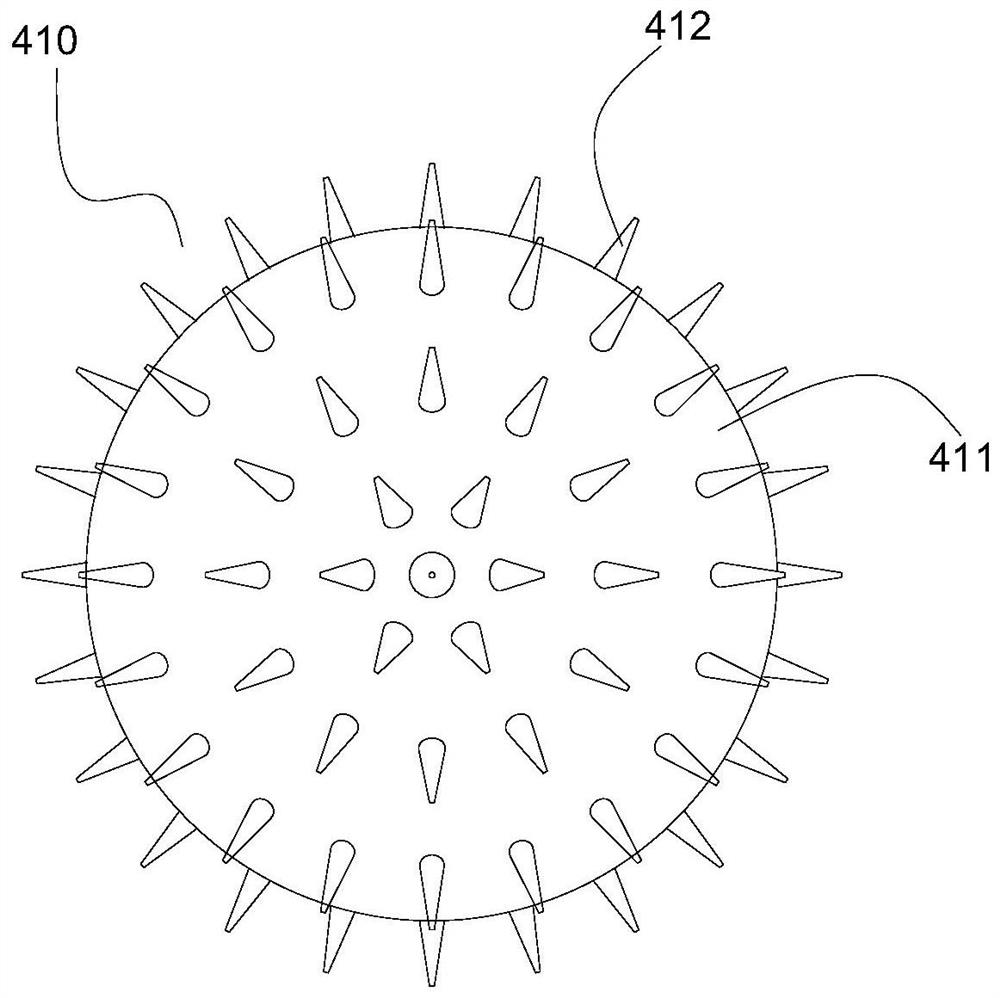

[0027] Such as Figure 1 to Figure 4 As shown, a specific embodiment of the present invention discloses an electrospinning nozzle structure based on the capillary principle, including a liquid storage tank 100, a splitter box 200 installed on the top of the liquid storage tank 100, and a guide tube installed on the top of the splitter box 200. The flow tube 300 adopts a detachable structure, which is convenient for production, processing and assembly; the middle part of the flow box 200 is provided with a socket 210 that runs through the upper and lower walls, and the top surface of the flow box 200 is provided with a plurality of air outlets 220, and the air outlets 220 and The distribution box 200 is internally connected, and the side wall of the distribution box 200 is connected with a gas supply pi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap