Three-dimensional memory and method for preparing three-dimensional memory

A memory and three-dimensional technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of increasing the curvature of the substrate of the semiconductor structure, increasing the difficulty of processing other process steps, and high heating temperature of the wafer. Improve performance, reduce cost, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

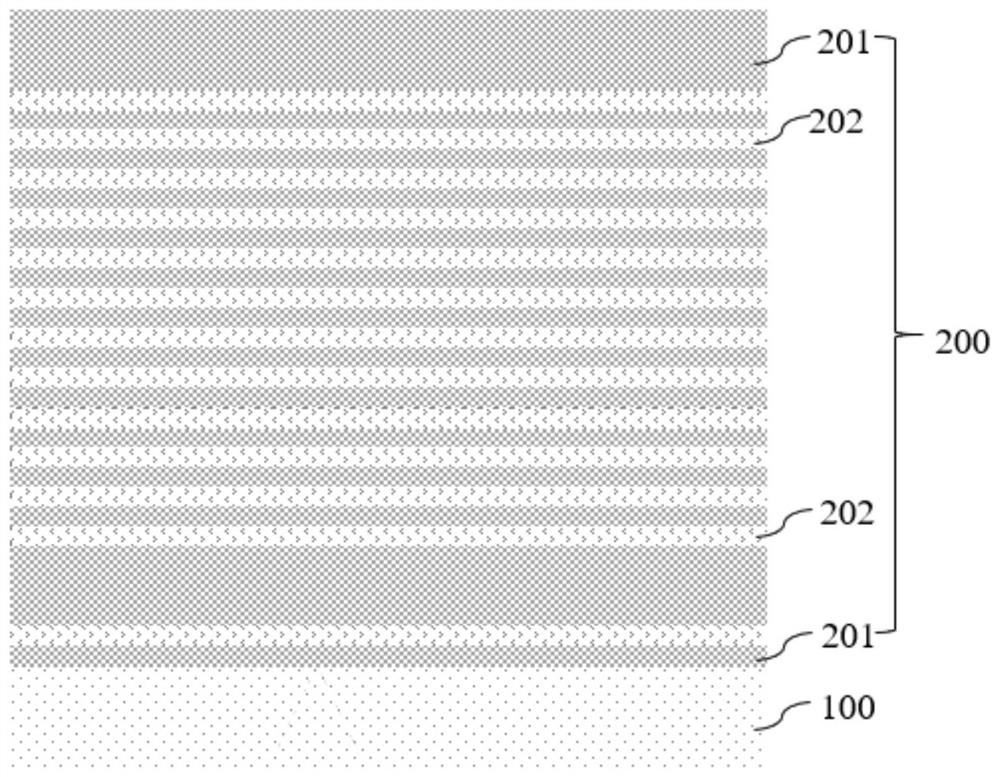

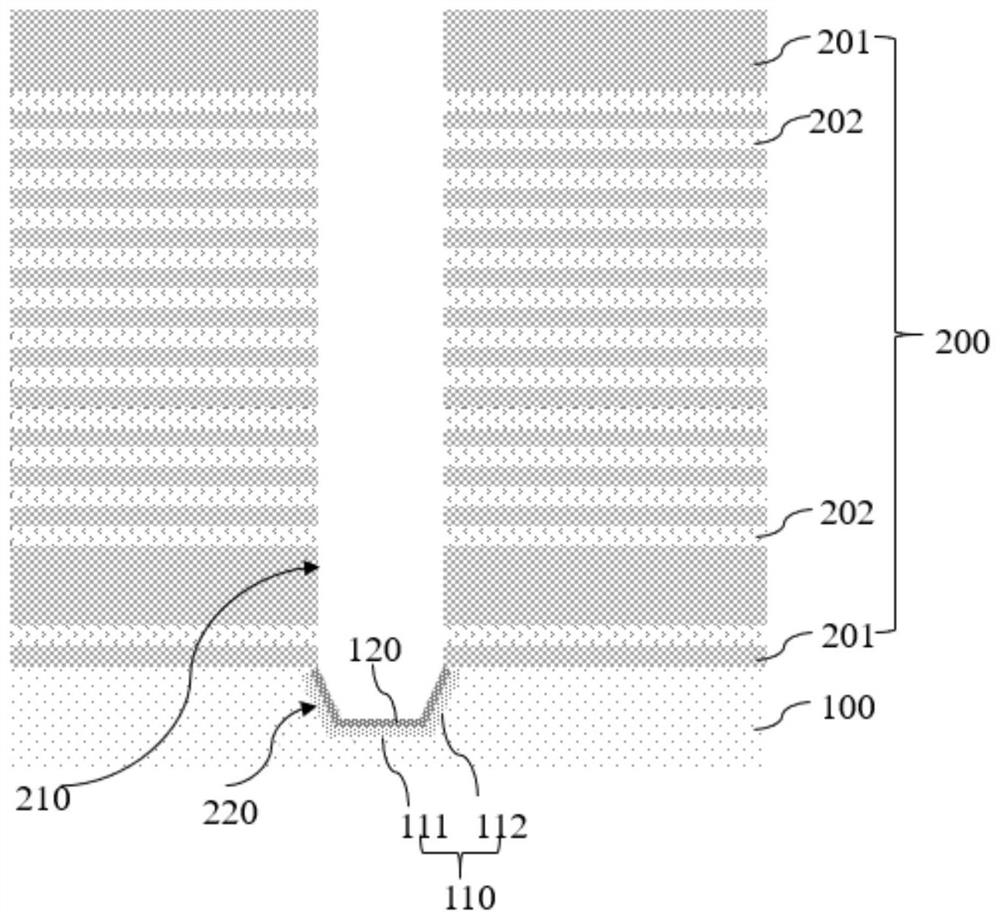

[0032] The present application will be described in detail below in conjunction with the accompanying drawings, and the exemplary implementations mentioned herein are only used to explain the present application, and are not intended to limit the scope of the present application.

[0033] The use of cross-hatching and / or shading is generally provided in the figures to clarify boundaries between adjacent elements. Accordingly, neither the presence nor absence of cross-hatching or shading conveys or indicates any assumptions about particular materials, material properties, dimensions, proportions, commonality between illustrated elements, and / or any other characteristics, properties, properties, etc. of the elements. preference or request unless otherwise stated. Furthermore, in the drawings, the size and relative sizes and shapes of elements have been adjusted for clarity and / or descriptive purposes. It should be understood that the drawings are only examples and are not st

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Pulse frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap