High-solid-content colored transparent coating composition as well as preparation method and application thereof

A transparent coating and composition technology, applied in the field of high-solid colored and transparent coating compositions, can solve the problems of being unsuitable for the protection of carbon fiber substrates, restricting wider use, and limited color effects, etc., to achieve rich colors , good water resistance, good gloss and distinct image effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

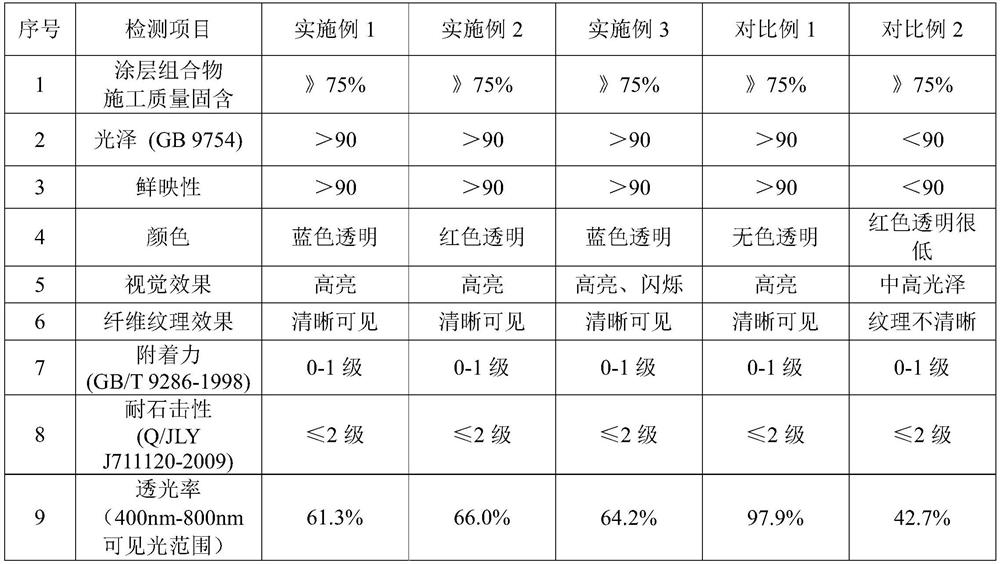

Examples

Embodiment 1

[0055] In this embodiment, a high-solid colored transparent coating composition 1 is provided, and the high-solid colored transparent coating composition 1 includes component A and component B, wherein,

[0056] A component comprises by weight:

[0057] Desmophen NH1420 78 parts;

[0058] 13 parts of butyl acetate;

[0059] 5 parts of propylene glycol methyl ether acetate;

[0060] Blue high transparent nano color paste (particle size about 150 nanometers) 2 parts

[0061] 0.15 parts of substrate wetting agent;

[0062] Wetting and dispersing agent 0.1 part;

[0063] Leveling agent 0.05 part;

[0064] 0.2 part of rheological additive;

[0065] 1 part of UV absorber;

[0066] 0.5 part of light stabilizer;

[0067] B component comprises by weight:

[0068] Desmodur N 3900 80 parts;

[0069] 10 parts of butyl acetate;

[0070] 10 parts of propylene glycol methyl ether acetate.

[0071] The specific steps of the preparation method of the above-mentioned high-solid colored

Embodiment 2

[0077] In this embodiment, a high-solid colored transparent coating composition 2 is provided, and the high-solid colored transparent coating composition 2 includes component A and component B, wherein,

[0078] A component comprises by weight:

[0079] Desmophen NH1420 78 parts;

[0080] 13 parts of butyl acetate;

[0081] 5 parts of propylene glycol methyl ether acetate;

[0082] Red high transparent nano color paste (particle size about 150 nanometers) 2 parts

[0083] 0.15 parts of substrate wetting agent;

[0084] Wetting and dispersing agent 0.1 part;

[0085] Leveling agent 0.05 part;

[0086] 0.2 part of rheological additive;

[0087] 1 part of UV absorber;

[0088] 0.5 part of light stabilizer;

[0089] B component comprises by weight:

[0090] Desmodur N 3900 80 parts;

[0091] 10 parts of butyl acetate;

[0092] 10 parts of propylene glycol methyl ether acetate.

[0093] The specific steps of the preparation method of the above-mentioned high-solid colored tr

Embodiment 3

[0099] In this embodiment, a high-solid colored transparent coating composition 3 is provided, and the high-solid colored transparent coating composition 3 includes component A and component B, wherein,

[0100] A component comprises by weight:

[0101] Desmophen NH1420 78 parts;

[0102] 13 parts of butyl acetate;

[0103] 5 parts of propylene glycol methyl ether acetate;

[0104] Blue high transparent nano color paste (particle size about 150 nanometers) 2 parts

[0105] 0.1 parts of pearl powder

[0106] 0.15 parts of substrate wetting agent;

[0107] Wetting and dispersing agent 0.1 part;

[0108] Leveling agent 0.05 part;

[0109] 0.2 part of rheological additive;

[0110] 1 part of UV absorber;

[0111] 0.5 part of light stabilizer;

[0112] B component comprises by weight:

[0113] Desmodur N 3900 80 parts;

[0114] 10 parts of butyl acetate;

[0115] 10 parts of propylene glycol methyl ether acetate.

[0116] The specific steps of the preparation method of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap